Niles Coyote

Plinker

I have wanted to try out a Bell & Carlson Tactical Medalist A3 since I first saw them a year or so ago. I had a few extra bucks from some OT at work so I splurged… The 308 Tactical is getting yet another face lift. I am impressed with the feel and quality of construction plus an added benefit, it’s a ¼ inch longer in pull so it should fit me a little better than the HS stock it is replacing… the backend doesn’t sound hollow either. Initial fitting was good but like to put a little love into my rifles and decided to skim bed it anyway.

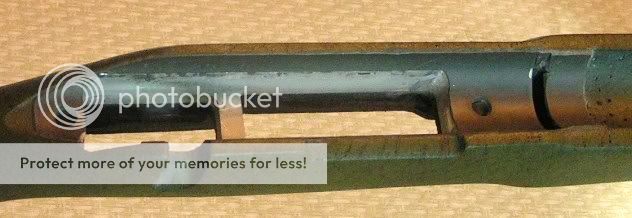

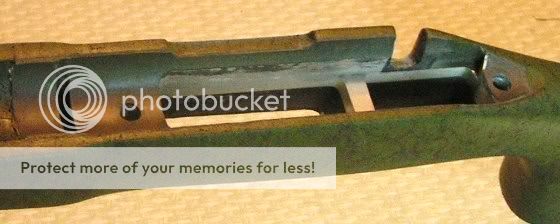

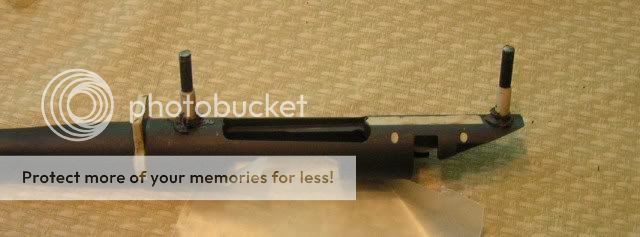

Step 1: Strip action down and mask barrel to support the action. This will allow no play in the action while the bedding compound hardens and act as a centering guide with in the barrel channel. Tape sides and front of recoil lug, this makes it easier to remove the action from the stock after the compound hardens. Screw in action screw guides and tape to fill and center the screws in the stock’s action block. You want the action clean, so to remove gun oils I use rubbing alcohol for this.

Step 2: Fill all voids with modeling clay

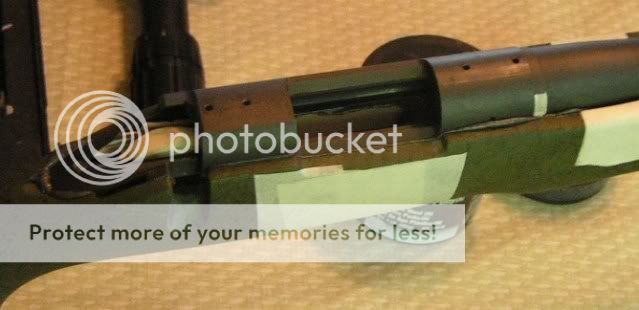

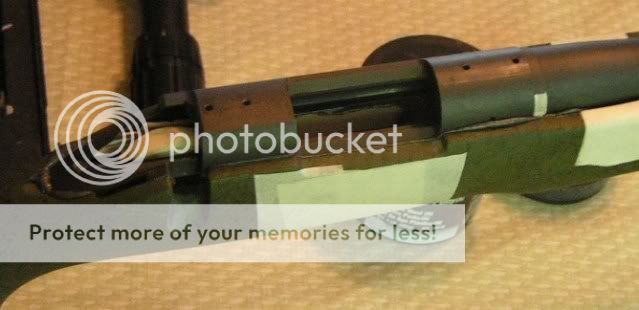

Step 3: Tape stock to form a little dam, I like to have a little barrel bed so I allowed about an inch and a half forward of where the lug will reside.

Step 4: Rough up the stock to give the compound something to adhere to and apply release agent (neutral shoe polish) to action and barrel. Apply the release agent on the barrel several inches forward of the lug. Be generous here as this keeps mistakes from happening.

Step 5: Since I am using Devcon here, I weight out a 9/1 mixture of bedding and hardener.

Step 6: After mixing/blending the two together for several minutes I apply the compound to the stock using toothpicks and work it into all the areas I want to be bedded and just about fill the lug well in the stock with compound.

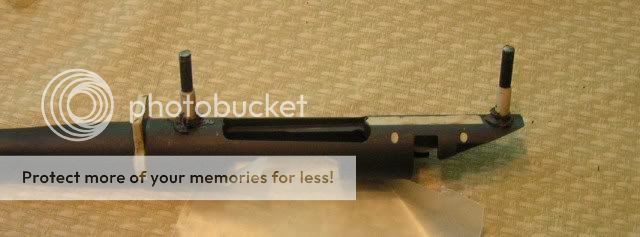

Step 7: Now apply a little compound around the action guides.

Step 8: Line the guides up and squeeze the action down into the stock until it can’t go in any deeper. Excess bedding will squeeze out around the action.

Step 9: clean off the excess that squeezed out with toothpicks to get the bulk of the bedding off, then I go back with Q-tips loaded with WD-40 and wipe off the remaining compound.

Step 1: Strip action down and mask barrel to support the action. This will allow no play in the action while the bedding compound hardens and act as a centering guide with in the barrel channel. Tape sides and front of recoil lug, this makes it easier to remove the action from the stock after the compound hardens. Screw in action screw guides and tape to fill and center the screws in the stock’s action block. You want the action clean, so to remove gun oils I use rubbing alcohol for this.

Step 2: Fill all voids with modeling clay

Step 3: Tape stock to form a little dam, I like to have a little barrel bed so I allowed about an inch and a half forward of where the lug will reside.

Step 4: Rough up the stock to give the compound something to adhere to and apply release agent (neutral shoe polish) to action and barrel. Apply the release agent on the barrel several inches forward of the lug. Be generous here as this keeps mistakes from happening.

Step 5: Since I am using Devcon here, I weight out a 9/1 mixture of bedding and hardener.

Step 6: After mixing/blending the two together for several minutes I apply the compound to the stock using toothpicks and work it into all the areas I want to be bedded and just about fill the lug well in the stock with compound.

Step 7: Now apply a little compound around the action guides.

Step 8: Line the guides up and squeeze the action down into the stock until it can’t go in any deeper. Excess bedding will squeeze out around the action.

Step 9: clean off the excess that squeezed out with toothpicks to get the bulk of the bedding off, then I go back with Q-tips loaded with WD-40 and wipe off the remaining compound.

Last edited: