Lost Californian

Expert

wellhell. Went to the barn to do some tractor work, and the lift won't lift. Heh, no air. Mebbe the pressure switch got stuck with the current weather changes, it has before. Nothing so easy.

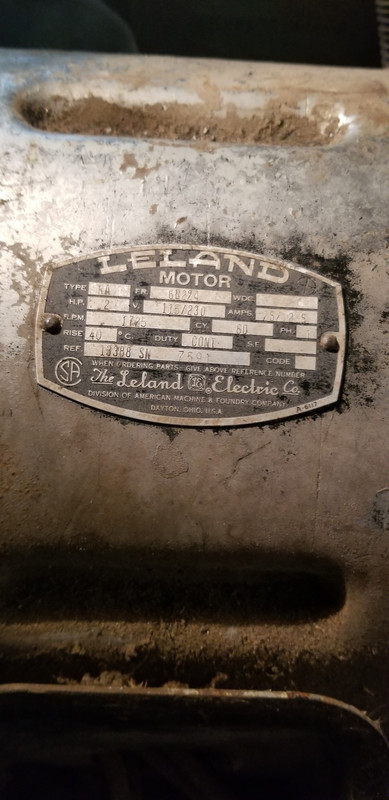

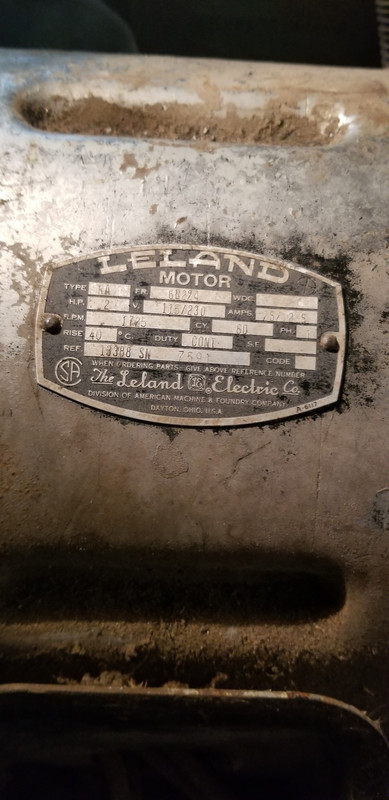

I have power to the motor, but the motor won't run. spin it by hand, and there is a not nice yucky sounding grinding. Here are pichers of the confounded thing...

Since the tank is 68 years old, I am guessing the rest of it is, also. Is it time to replace the entire setup, or just see about finding a new 2hp electric motor that would fit this thing?

I ain't knowledgeable about these things.

I have power to the motor, but the motor won't run. spin it by hand, and there is a not nice yucky sounding grinding. Here are pichers of the confounded thing...

Since the tank is 68 years old, I am guessing the rest of it is, also. Is it time to replace the entire setup, or just see about finding a new 2hp electric motor that would fit this thing?

I ain't knowledgeable about these things.