-

Be sure to read this post! Beware of scammers. https://www.indianagunowners.com/threads/classifieds-new-online-payment-guidelines-rules-paypal-venmo-zelle-etc.511734/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Drill Bits breaking

- Thread starter radar8756

- Start date

The #1 community for Gun Owners in Indiana

Member Benefits:

Fewer Ads! Discuss all aspects of firearm ownership Discuss anti-gun legislation Buy, sell, and trade in the classified section Chat with Local gun shops, ranges, trainers & other businesses Discover free outdoor shooting areas View up to date on firearm-related events Share photos & video with other members ...and so much more!

Member Benefits:

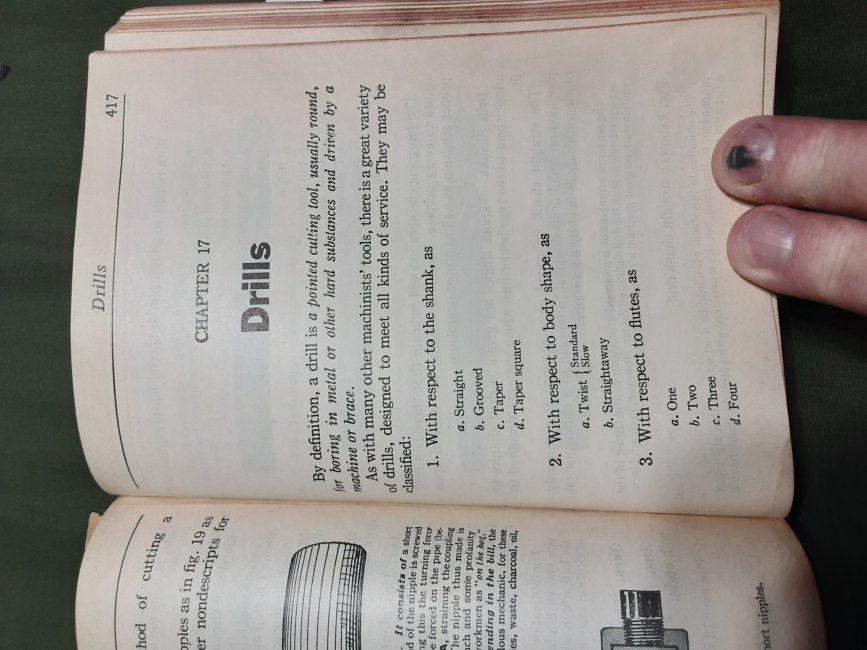

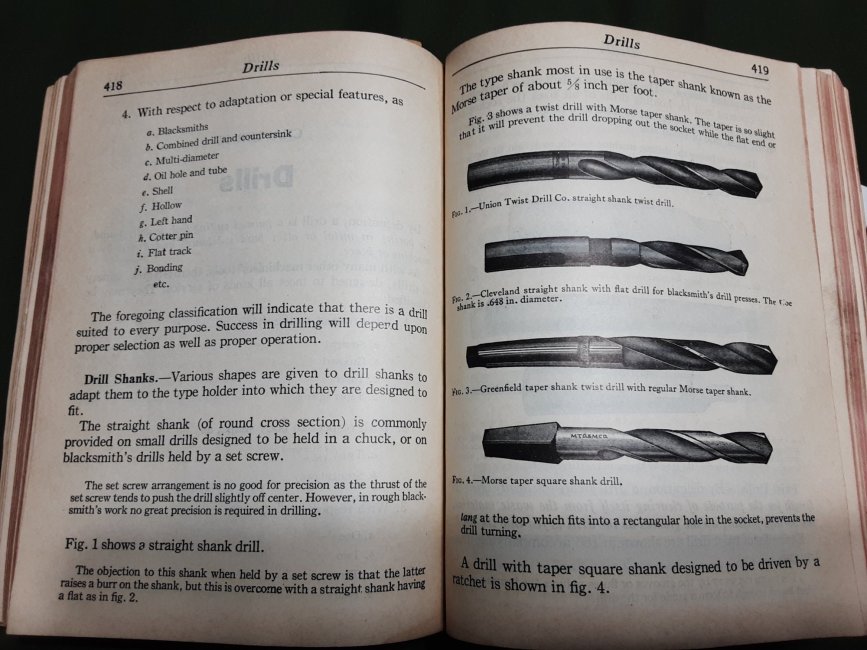

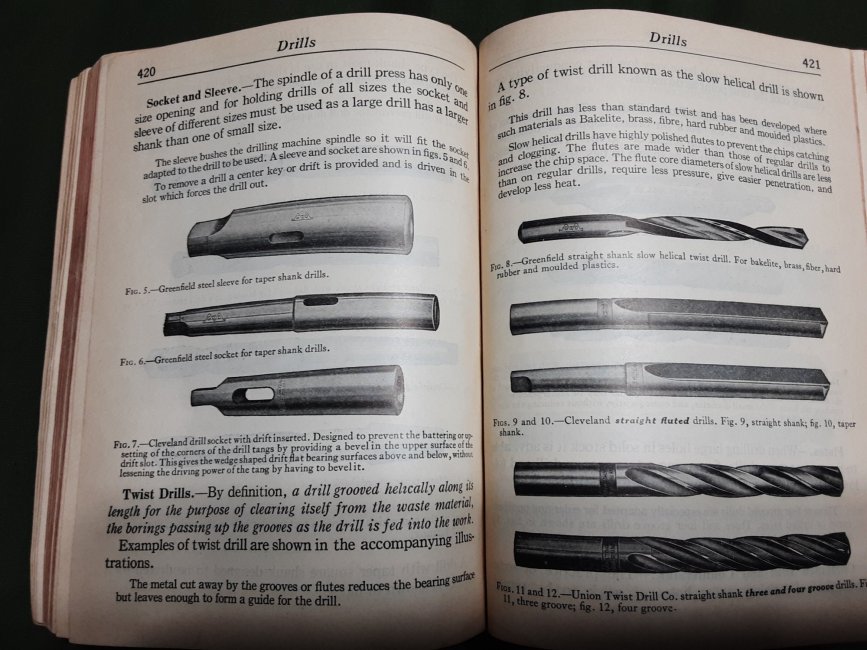

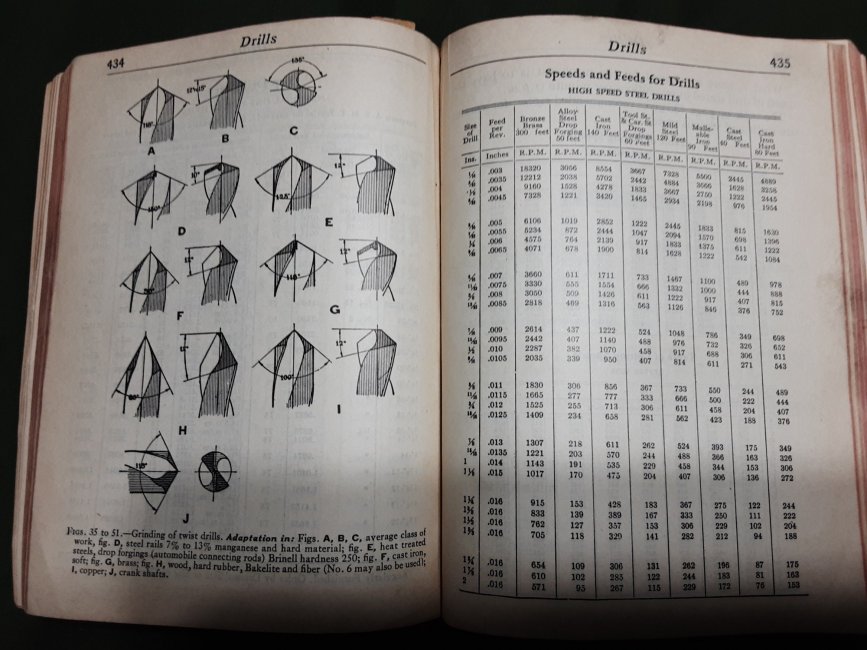

This reminds me of the clip vs magazine conundrumI checked 3 different machinist & tool maker books I own. No mention of drill bits, small sample from this particular book. View attachment 257543 View attachment 257544 View attachment 257545 View attachment 257546 View attachment 257547

Question for @55fairlane ... What do you call this?

I'll give you a hint Wheel of Fortune style... __race and __it

I'll give you a hint Wheel of Fortune style... __race and __it

Jaybird1980

Grandmaster

Pain in the A** is what I call themQuestion for @55fairlane ... What do you call this?

I'll give you a hint Wheel of Fortune style... __race and __it

View attachment 257591

The first cordless drill?Question for @55fairlane ... What do you call this?

I'll give you a hint Wheel of Fortune style... __race and __it

View attachment 257591

I have one and like it! The hole into which my drive through gate's drop rod falls sometimes gets clogged with dirt and debris, and it's perfect for clearing it.Pain in the Ass is what I call them

No. According to 55fairlane, all "drills" are cordless since they're just pieces of metal designed to poke holes in things.The first cordless drill?

Jaybird1980

Grandmaster

I know the first time I worked with someone from overseas he asked me for a drill and I handed him my cordless. He was confused, then I was confused. We got it sorted out though.No. According to 55fairlane, all "drills" are cordless since they're just pieces of metal designed to poke holes in things.

He called them drills and drill machines.

Maybe 55fairlane is from overseas.I know the first time I worked with someone from overseas he asked me for a drill and I handed him my cordless. He was confused, then I was confused. We got it sorted out though.

He called them drills and drill machines.

Kidding aside, he is the only one I've seen referring to them as "drills" as opposed to "drill bits" in my 63 years on this earth. Obviously he posted some evidence that they were indeed referred to as such back in the olden days.

Kidding aside, he is the only one I've seen referring to them as "drills" as opposed to "drill bits" in my 63 years on this earth. Obviously he posted some evidence that they were indeed referred to as such back in the olden days.Jaybird1980

Grandmaster

They're still referred to as drills by some people in the trades, especially during training or literature. I had never heard it until I was 18 or so on the job.Maybe 55fairlane is from overseas.Kidding aside, he is the only one I've seen referring to them as "drills" as opposed to "drill bits" in my 63 years on this earth. Obviously he posted some evidence that they were indeed referred to as such back in the olden days.

Kind of like Bolts and Screws. In some a bolt is a screw until it has a nut, but with most a screw is tapered and bolts are not.

Machine screws have a nut. Sometimes a nut just means the screw is over...Kind of like Bolts and Screws. In some a bolt is a screw until it has a nut, but with most a screw is tapered and bolts are not.

Jaybird1980

Grandmaster

A machine screw is a bolt in a lot of literatureMachine screws have a nut. Sometimes a nut just means the screw is over...

And sometimes you have to bolt in the middle of a screw...A machine screw is a bolt in a lot of literature

An idiot tool? Cause only an idiot wants to drill holes with this tool....Question for @55fairlane ... What do you call this?

I'll give you a hint Wheel of Fortune style... __race and __it

View attachment 257591

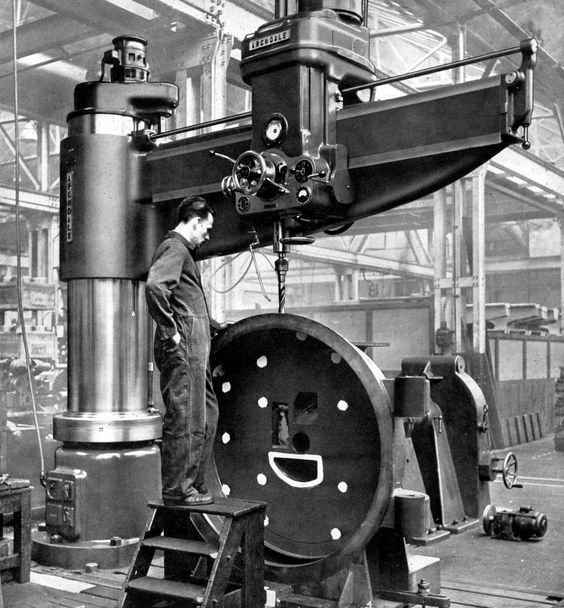

A drill motor is the habd held item used to power a drill. To be more technical there are, cordless drill motor, an air powered drill motor, a drill press ......and radial arm drill press, like the one in this pictureI know the first time I worked with someone from overseas he asked me for a drill and I handed him my cordless. He was confused, then I was confused. We got it sorted out though.

He called them drills and drill machines.

Drills make cylindrical shapes voids in metalNo. According to 55fairlane, all "drills" are cordless since they're just pieces of metal designed to poke holes in things.

Reamers take the "hole" to size

Counter bores add an additional cylindrical shaped void , true to the axis line of the "hole"

A drill motor is the habd held item used to power a drill. To be more technical there are, cordless drill motor, an air powered drill motor, a drill press ......and radial arm drill press, like the one in this picture View attachment 257651

In my younger days in the trades I worked with some old timers (and great workers) who would refer to the mechanical object that twists the drill [bit], as a “drill motor”. I don’t recall what they called the drills.

Double Margin drills have an additional margin ground behind the leading margin,providing twice the number of contact points.The second margin performs various functions to improve hole quality.

- The trailing margin burnishes the cavity, making a true hole and smoother finish, helping to provide a more concentric drilled hole

- A reamer finish can be achieved with double margin drills, eliminating a second operation.

- When a double margin drill is used with a drill bushing, the four margins locate in the bushing, providing increased bushing support in excess of 200%.

- When intermittent cutting is required, the double margin drill performs in two ways: Enhanced margin support in the first cavity cut, and support on breakthrough, which stops the drill from wandering when in contact with the work space.

- Drill back taper is more tightly controlled than a regular drill, enhancing a rounder hole location.

- 135-degree split point provides immediate self-centering on contact with the work piece, and reduces thrust, due to its notch-type web thinning at the chisel edge length. The split point is excellent for drilling harder materials (titanium, stainless steel, and high temperature alloys.)

- Will all these features incorporated in this double margin drill, it is excellent for hand drilling.

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

Members online

- 68kidd

- DoggyDaddy

- Dutchmaster

- erasure

- Creedmoor

- SEIndSAM

- 63PGP

- XDdreams

- 2tonic

- ROOTS54454

- Tradesylver

- snapping turtle

- nad63

- nobletucky

- backtrail540

- Indy574

- NHT3

- junglerogue

- slims2002

- snowwalker

- Dean C.

- jbm1521

- WhitleyStu

- 42769vette

- simpleman44

- 357 Terms

- JimH

- CMB69

- Slow Hand

- phylodog

- Count Blackula

- Mgderf

- Timjoebillybob

- pewpew2232

- Reece'sPieces

- rdbs505

- vzdude

- Glocktard

- Rafterman

- buckwheat65

- DDadams

- x34822

- FireBirdDS

- JAL

- Squid556

Total: 1,532 (members: 52, guests: 1,480)