I am starting a new project this week. A little more challenging then assembling a AR15 or a 10-22 trigger job. Those are fun too but get to be a little to routine after a few dozen.

I am taking a WW2 British sub machine parts kit and turning it in to a semi auto pistol. I really wanted to do this as a semi auto rifle. But there are too many hoops to jump threw for 922r compliance. It can be done and I will do one sooner or later. The Mark V is the one I really want to as a rifle.

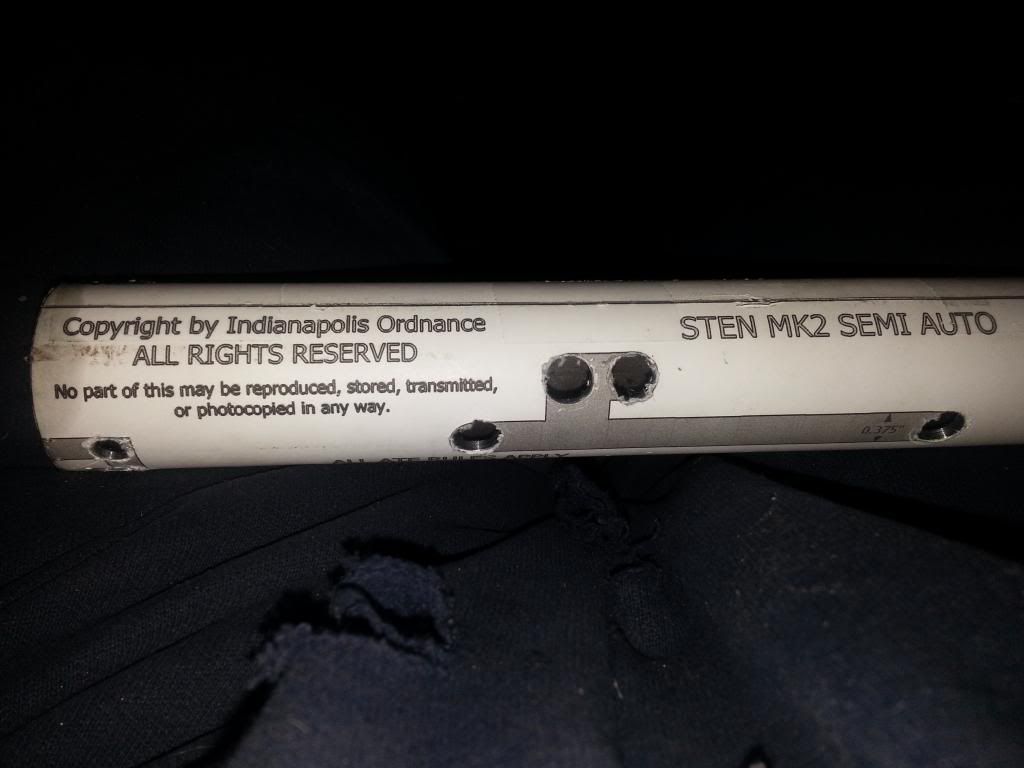

The semi auto conversion and receiver tube blank is from Indianapolis Ordnance. The Sten Gun parts kits are available from a lot of sources. The Sten came in many versions and configurations. It is well worth Googling Sten Gun if you are a weaposns history buff. If you want to know what a completed one looks like Google it or I am gonna make you wait! I am mean Iike that.

I have several versions of the Sten. This will be my first build. It's a pretty simple build(so it seems). A Dremel tool or mill, welder, drill press or drill and a few hand tools is all you need to get started. It will be fully legal when complete. The original full auto bolt will not fit in. Semi auto only. A rifle stock will not fit on it. I want any ATF worries.

Here is the semi auto kit:

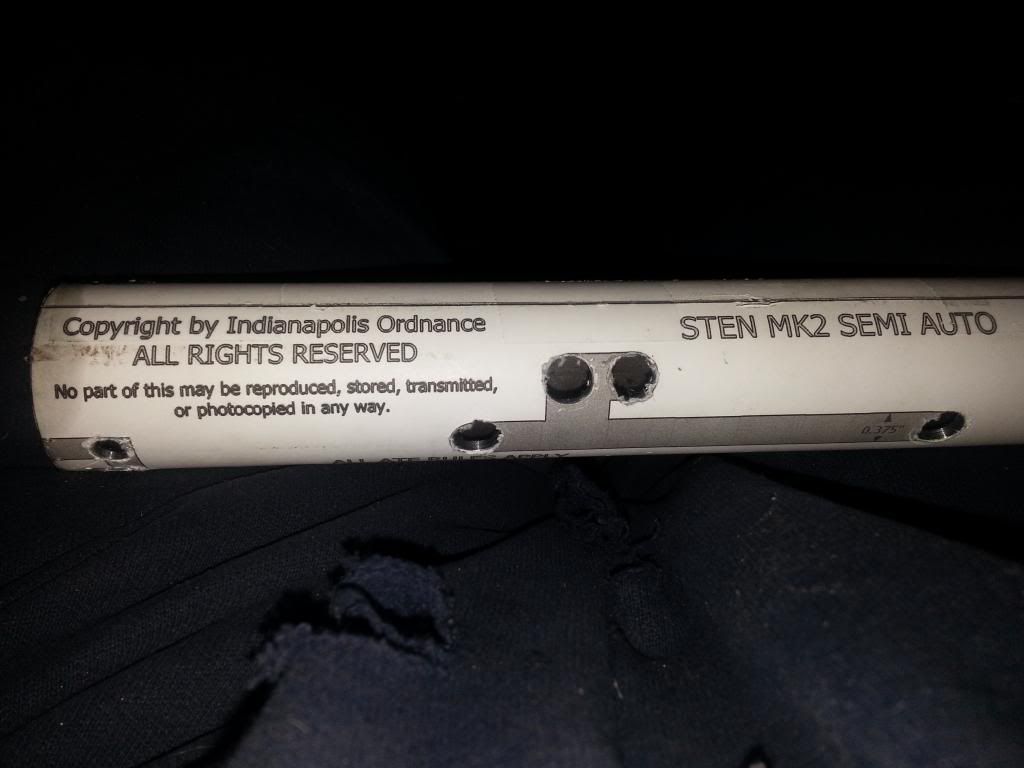

I drilled the holes to start the cuts:

The mag well and ejection port cut Front barrel nut is just pushed in place. It will be welded. I did the cuts with a dremel. I was going to use the mill but my back is killing me and I was able to sit and dremel. It was not as hard as it sounds. I will use the mill on the major cuts next time.

The charging handle slots are cut out and the bolt is fit. It slides freely and seems great.

Lots more to do. Stripping the parts kit is next. Then welding the barrel nut and the trigger guard. Then putting in the semi auto bolt kit and lots of tuning to make reliable. Then I have to decide on the finish. I think that will be an AllenM job. I am going to need a dove tail cut for the front sight. Maybe a AllenM job too?

.

I am having a medical procedure done tomorrow so I will be a little delayed in getting it complete. Hopefully I will get it shooting in the week or so. Providing I have no major issues with me or the buld. I am in uncharted territory on this build. Hopefully all goes well.

More info to follow... Stay tuned...

I am taking a WW2 British sub machine parts kit and turning it in to a semi auto pistol. I really wanted to do this as a semi auto rifle. But there are too many hoops to jump threw for 922r compliance. It can be done and I will do one sooner or later. The Mark V is the one I really want to as a rifle.

The semi auto conversion and receiver tube blank is from Indianapolis Ordnance. The Sten Gun parts kits are available from a lot of sources. The Sten came in many versions and configurations. It is well worth Googling Sten Gun if you are a weaposns history buff. If you want to know what a completed one looks like Google it or I am gonna make you wait! I am mean Iike that.

I have several versions of the Sten. This will be my first build. It's a pretty simple build(so it seems). A Dremel tool or mill, welder, drill press or drill and a few hand tools is all you need to get started. It will be fully legal when complete. The original full auto bolt will not fit in. Semi auto only. A rifle stock will not fit on it. I want any ATF worries.

Here is the semi auto kit:

I drilled the holes to start the cuts:

The mag well and ejection port cut Front barrel nut is just pushed in place. It will be welded. I did the cuts with a dremel. I was going to use the mill but my back is killing me and I was able to sit and dremel. It was not as hard as it sounds. I will use the mill on the major cuts next time.

The charging handle slots are cut out and the bolt is fit. It slides freely and seems great.

Lots more to do. Stripping the parts kit is next. Then welding the barrel nut and the trigger guard. Then putting in the semi auto bolt kit and lots of tuning to make reliable. Then I have to decide on the finish. I think that will be an AllenM job. I am going to need a dove tail cut for the front sight. Maybe a AllenM job too?

.

I am having a medical procedure done tomorrow so I will be a little delayed in getting it complete. Hopefully I will get it shooting in the week or so. Providing I have no major issues with me or the buld. I am in uncharted territory on this build. Hopefully all goes well.

More info to follow... Stay tuned...

) just use a really tiny piece of paper and put it between the ejector and the tube. It makes it a breeze to weld the ejector. It will stay in place while you weld it. The paper will just burn away. Put the bolt cocking lever in the bolt to keep it centered. If for some reason you don't end up with enough clearance you can dremel the ejector edge a little. The ejector tab has to only be close. As long as the bolt moves free and the tab hits the back of the shell it will work.

) just use a really tiny piece of paper and put it between the ejector and the tube. It makes it a breeze to weld the ejector. It will stay in place while you weld it. The paper will just burn away. Put the bolt cocking lever in the bolt to keep it centered. If for some reason you don't end up with enough clearance you can dremel the ejector edge a little. The ejector tab has to only be close. As long as the bolt moves free and the tab hits the back of the shell it will work.