Inlaws brought me a wiring harness today to fix.

Suddenly their wood shop breaker tripped. So they started unplugging things. Eventually they discovered it was their 30+YO saw. The insulation on the cord dried out and shorted.

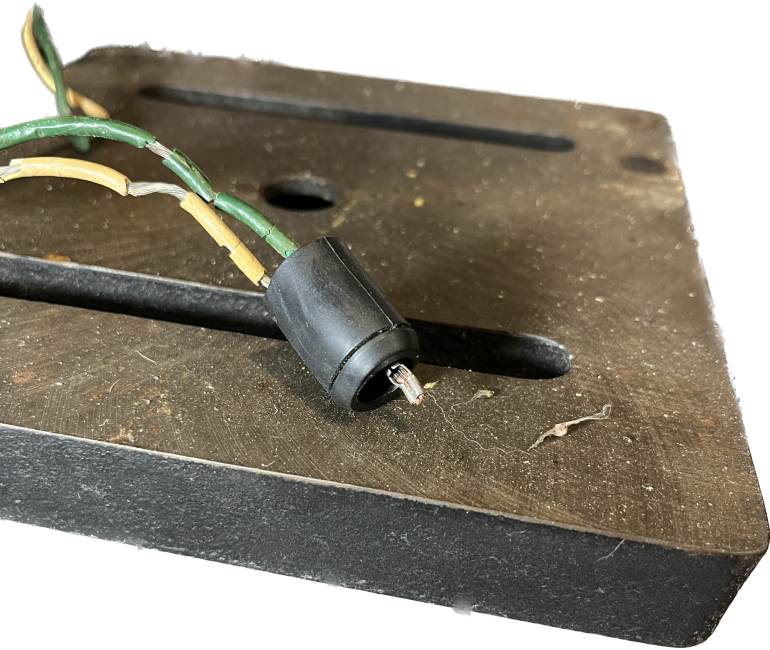

But the connection between the cord and the motor is unique. And there is not enough wire on the motor side to replace the QD connector.

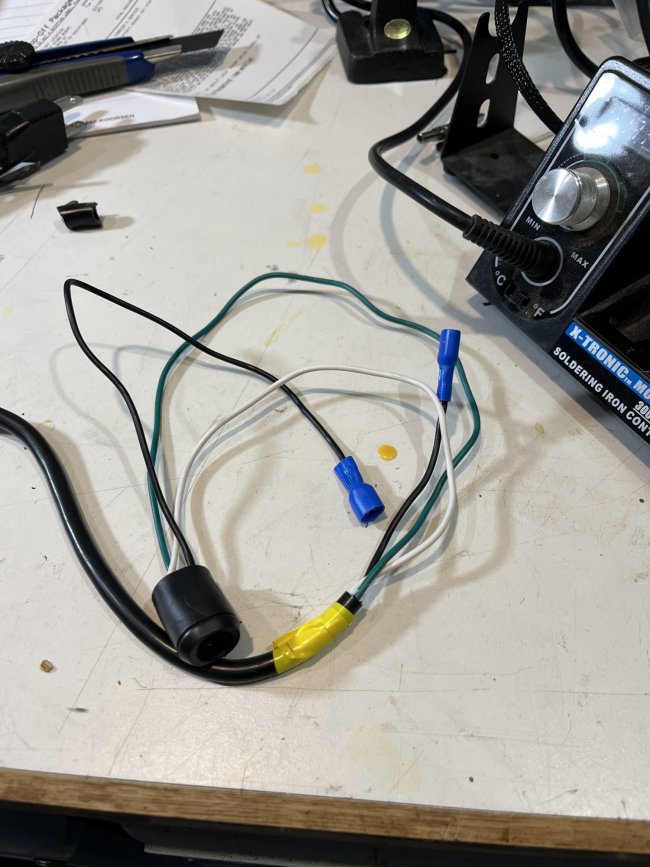

I can pull the individual barrel contacts from the cord and reattach wires to rebuild it with a new cord. But its going to be a tight fit in the rubber housing if I just try to solder a new wire to the old crimp leaves. Its a 2 leaf fold over style crimp where its stamped out as a T and the two leaves are folded over together to crimp onto the wire. But I dont see an easy way to get anything under the leaves to open them back up.

ideas? Its not a cheap saw and it works awesome otherwise, so not something they want to just replace. Plus they are retired, so income isnt as plentiful as it used to be.

Ideas?

Suddenly their wood shop breaker tripped. So they started unplugging things. Eventually they discovered it was their 30+YO saw. The insulation on the cord dried out and shorted.

But the connection between the cord and the motor is unique. And there is not enough wire on the motor side to replace the QD connector.

I can pull the individual barrel contacts from the cord and reattach wires to rebuild it with a new cord. But its going to be a tight fit in the rubber housing if I just try to solder a new wire to the old crimp leaves. Its a 2 leaf fold over style crimp where its stamped out as a T and the two leaves are folded over together to crimp onto the wire. But I dont see an easy way to get anything under the leaves to open them back up.

ideas? Its not a cheap saw and it works awesome otherwise, so not something they want to just replace. Plus they are retired, so income isnt as plentiful as it used to be.

Ideas?