... I've been contemplating making a glue-laminate one out of wood and sheet metal just to see if I can, not for any practical reason...

Ooh, I'd like to see some pics of how this goes.

Thanks for the review Robby!

... I've been contemplating making a glue-laminate one out of wood and sheet metal just to see if I can, not for any practical reason...

If you ever decide to "give one away", I'll take the one with theand the "Pants/No Pants" selector.

Update:

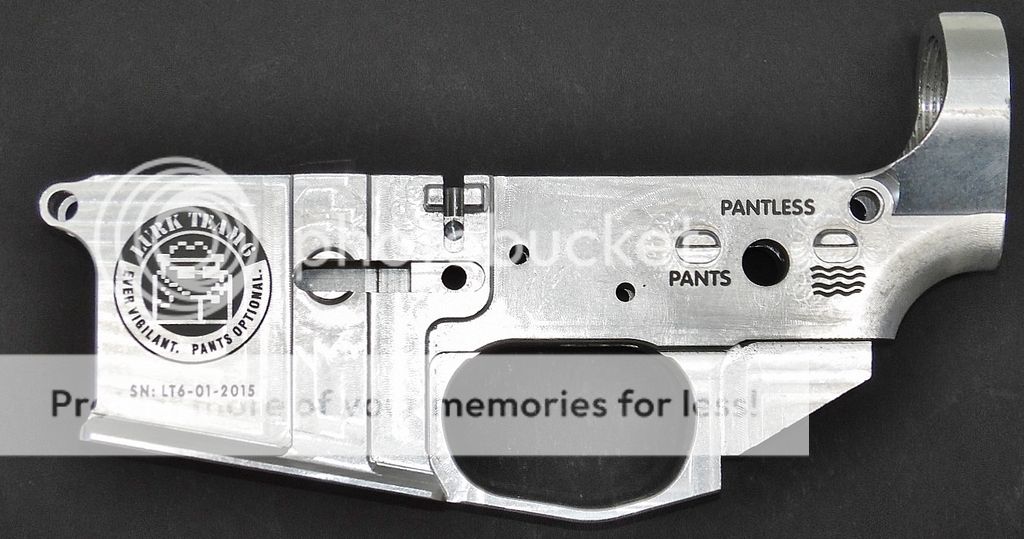

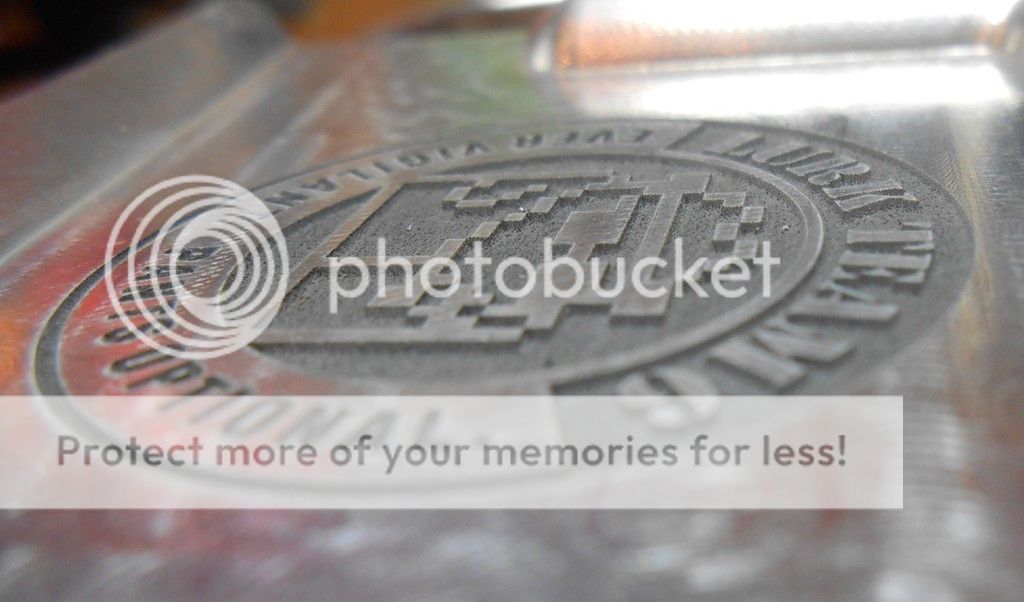

Got my lowers back from INGO Advertiser Veritas. They did a most excellent job laser engraving the lowers!!!!

Awesome experience. Amazing detail to be had with their lasers. I feel bad for having such great engraving done on my shadetree milled lower!!!

If LT6 existed, they might have a lower that looks something like this:

Now to get them media blasted, and decide what sort of finish I want

OMG!!! F'n awesome Robby!!! I love it.

What is this LT-6 you speak of??

QFT!!This project is getting awesomer and awesomer!

Based on this thread I got the EZ jig and did my first lower. Took about three hours over the course of an afternoon and other than having to slightly ream out te safety selector hole the LPK went in no problem.

You know the drill, pics or it didn't happen!

Nope, I ain't selling it so you get no pics. But imagine if you will, a mirror bright sheen on the internal millings, a nice contrast to the black anodizing on the outside. I imagine that too because it looks more like something someone gouged out with a dremel. Well, not quite, but it's functional so that's all I care about. I have four more to make.

Did you guys run the tools dry. I use wax or oil to keep the tools clear of chips so they cut smoother.

Did you guys run the tools dry. I use wax or oil to keep the tools clear of chips so they cut smoother.

I used cutting fluid liberally throughout. I put some in the flutes up high so it can run down the tool and I also puddle it at the cutting surfaces.

Update:

Got my lowers back from INGO Advertiser Veritas Machining. They did a most excellent job laser engraving the lowers!!!!

Awesome experience. Amazing detail to be had with their lasers. I feel bad for having such great engraving done on my shadetree milled lower!!!

If LT6 existed, they might have a lower that looks something like this:

Now to get them media blasted, and decide what sort of finish I want