ROLEXrifleman

Master

There are many factors that go into a precision rifle. What you are about to read is the break down on one of the few “from the ground up” built “sniper” weapon systems. Here is the break down on the Accuracy International AT model. While this model is no longer in production you can se how it spawned the AW model currently in use and has but 2 changes, one for the better and one for the … well I’ll let you decide.

At a quick glance the AI rifle seems like nothing more than a traditional bolt gun with a thumbhole stock. Dig a little deeper and you will find this is the furthest thing from average.

By removing 8 screws you are able to strip away the skin of this rifle to expose what it really is.

A bomb proof factory built custom that exceeds about every option imaginable.

You begin with a steel, precision machined square action with integral recoil lug. The machining of this action holds tolerances so close that you can take the bolt from ANY other rifle of the same caliber and model and use it with no issue. They then take this action and PERAMNETLY attach it to the aluminum chassis with 4 bolts and epoxy making it a NON – user serviceable item. Unlike the common rifle where you can swap stocks out as you feel this rifle gives you no option for this. Part of what makes this weapon system what it is, is the fact that this “option” isn’t an option. So right off the bat we start with a “trued” action, a bomb proof, non warping aluminum chassis and a bedding job that marries it all together. Things that most people have done as an after thought when they have their “custom” gun built is done right from the factory with AI.

In addition, you have an adjustable cheek piece built in to the rear of the stock along with adjustable recoil pad.

Detachable box magazine is an internal part of the one piece chassis and uses the ever popular Accuracy International magazine that many other companies don’t even bother to try and copy. They just buy AI mags and include them with their product.

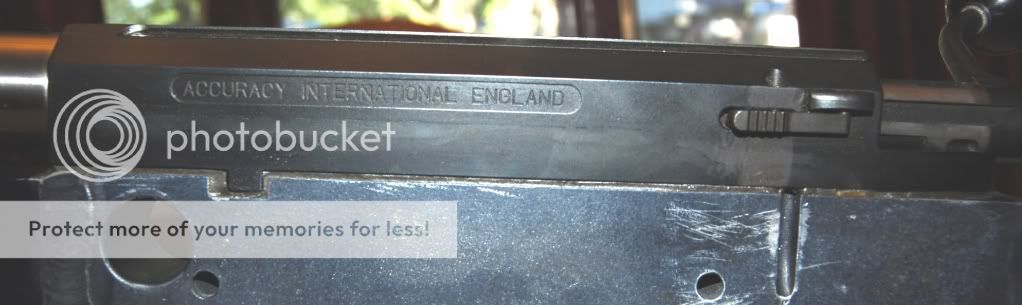

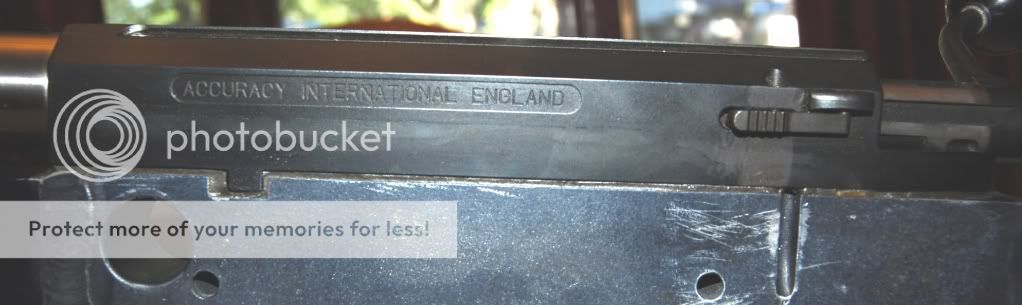

We now come to the bolt. Again, held to tolerances that allow the use of any matching caliber gun to be shot with any matching bolt, this in itself is a feat not even capable by 99% of custom guns out there. You’ll also notice that the bolt stop is of the push button design located on the action, not part of the trigger.

A key feature of the bolt that is noticeable right away is the fact that it has machined grooves in it. These grooves were designed in order to help break up ice that might have built up on the bolt in harsh arctic conditions. In addition they help to funnel away any debris that may jam the bolt. Oversized bolt handle and cocking indicator round out the basic features.

Next are the two features that differ from the AW series.

1) The safety. On the AT model it is a 2 position safety, you are either in SAFE or FIRE. In safe the firing pin is blocked and the bolt is able to be manipulated. The AW model offers a 3rd position that allows the bolt to be locked closed and the firing pin blocked. ( safety pictured above)

2) The Bolt head itself. The AT model has 6 locking lugs to hold it on place while the AW has 3. In comparison the Remington 700 and variants have but 2 locking lugs. Even an over pressured round will have a hard time shearing these lugs off.

Moving forward of the bolt and action we come to the match grade 26” SS 1:11.25. As you can see from the picture this barrel is completely free floated and makes no contact with anything other than the threads holding it in the action. Yet again, the machining of these items allows for ANY barrel cut for this rifle to simply be spun on and torque with no need for head spacing of any kind.

We now flip the gun over on it’s back to address it’s modular trigger. The trigger can be removed at any time by simply taking off the skins and removing the two bolts that keep it’s retainer plate fastened. Once the plate is removed the trigger can be easily pulled free. The trigger is adjustable for both pull weight and sear engagement by using a 2mm allen to adjust the corresponding screw. A nice window is also provided for visual inspection of sear engagement. ( also pictured are the 4 bolts that aid in attaching the action to the chassis)

And finally we come to the dovetail. AI, while offering pic rails as an option, pride themselves on the dovetail design. The dove tail is machined directly into the receiver as a 0 MOA mount. With the dovetail being machined into the receiver and the high level of QC that goes into these rifles what you don’t have is receiver that may have issues to begin with, you don’t have screw holes that you hope were drilled properly and square, you don’t have to mount a separate scope base that you hope was machined correctly… etc. By keeping it simple and doing it right in the 1st place there design IS the platform to beat in the long range game. (another image that shows this well is the one that shows the bolt release)

While this post has been an overview of the AI rifle system, keep it in mind as I further document the assembly of my “tack driver” and you will see how all my posts in this series are directly related.

And as a side note, the average cost of a base model AI AW is $5,500.00

At a quick glance the AI rifle seems like nothing more than a traditional bolt gun with a thumbhole stock. Dig a little deeper and you will find this is the furthest thing from average.

By removing 8 screws you are able to strip away the skin of this rifle to expose what it really is.

A bomb proof factory built custom that exceeds about every option imaginable.

You begin with a steel, precision machined square action with integral recoil lug. The machining of this action holds tolerances so close that you can take the bolt from ANY other rifle of the same caliber and model and use it with no issue. They then take this action and PERAMNETLY attach it to the aluminum chassis with 4 bolts and epoxy making it a NON – user serviceable item. Unlike the common rifle where you can swap stocks out as you feel this rifle gives you no option for this. Part of what makes this weapon system what it is, is the fact that this “option” isn’t an option. So right off the bat we start with a “trued” action, a bomb proof, non warping aluminum chassis and a bedding job that marries it all together. Things that most people have done as an after thought when they have their “custom” gun built is done right from the factory with AI.

In addition, you have an adjustable cheek piece built in to the rear of the stock along with adjustable recoil pad.

Detachable box magazine is an internal part of the one piece chassis and uses the ever popular Accuracy International magazine that many other companies don’t even bother to try and copy. They just buy AI mags and include them with their product.

We now come to the bolt. Again, held to tolerances that allow the use of any matching caliber gun to be shot with any matching bolt, this in itself is a feat not even capable by 99% of custom guns out there. You’ll also notice that the bolt stop is of the push button design located on the action, not part of the trigger.

A key feature of the bolt that is noticeable right away is the fact that it has machined grooves in it. These grooves were designed in order to help break up ice that might have built up on the bolt in harsh arctic conditions. In addition they help to funnel away any debris that may jam the bolt. Oversized bolt handle and cocking indicator round out the basic features.

Next are the two features that differ from the AW series.

1) The safety. On the AT model it is a 2 position safety, you are either in SAFE or FIRE. In safe the firing pin is blocked and the bolt is able to be manipulated. The AW model offers a 3rd position that allows the bolt to be locked closed and the firing pin blocked. ( safety pictured above)

2) The Bolt head itself. The AT model has 6 locking lugs to hold it on place while the AW has 3. In comparison the Remington 700 and variants have but 2 locking lugs. Even an over pressured round will have a hard time shearing these lugs off.

Moving forward of the bolt and action we come to the match grade 26” SS 1:11.25. As you can see from the picture this barrel is completely free floated and makes no contact with anything other than the threads holding it in the action. Yet again, the machining of these items allows for ANY barrel cut for this rifle to simply be spun on and torque with no need for head spacing of any kind.

We now flip the gun over on it’s back to address it’s modular trigger. The trigger can be removed at any time by simply taking off the skins and removing the two bolts that keep it’s retainer plate fastened. Once the plate is removed the trigger can be easily pulled free. The trigger is adjustable for both pull weight and sear engagement by using a 2mm allen to adjust the corresponding screw. A nice window is also provided for visual inspection of sear engagement. ( also pictured are the 4 bolts that aid in attaching the action to the chassis)

And finally we come to the dovetail. AI, while offering pic rails as an option, pride themselves on the dovetail design. The dove tail is machined directly into the receiver as a 0 MOA mount. With the dovetail being machined into the receiver and the high level of QC that goes into these rifles what you don’t have is receiver that may have issues to begin with, you don’t have screw holes that you hope were drilled properly and square, you don’t have to mount a separate scope base that you hope was machined correctly… etc. By keeping it simple and doing it right in the 1st place there design IS the platform to beat in the long range game. (another image that shows this well is the one that shows the bolt release)

While this post has been an overview of the AI rifle system, keep it in mind as I further document the assembly of my “tack driver” and you will see how all my posts in this series are directly related.

And as a side note, the average cost of a base model AI AW is $5,500.00

*************************

Original thread here: https://www.indianagunowners.com/forums/long_guns/104543-pt_2_anatomy_of_a_true_sniper_rifle.html

Original thread here: https://www.indianagunowners.com/forums/long_guns/104543-pt_2_anatomy_of_a_true_sniper_rifle.html

Last edited by a moderator: