I am not saying the half-inch socket is the problem.Why are you so hung up on the 1/2"? It is nothing more than the size of the whole in the socket. Rookie tried to explain that earlier, and you just seem to ignore it.

I've used 1/2" drive sockets with my impact driver on a number of occasions. I either didn't have a smaller drive version of the socket, or I was too lazy to find the one I needed. There is nothing odd about doing so.

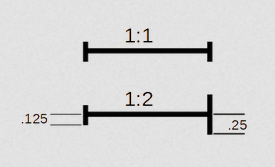

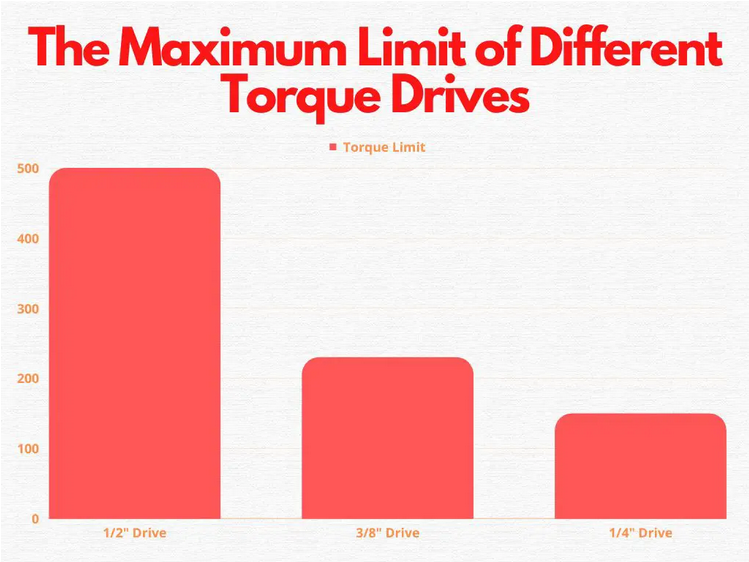

It’s because the torque is being transferred from the driver through a 1/4” shaft that could never hold up to the torque that the 1/2” square drive attached to it can place on it.

For an example, let’s say you have a 1/4” driveshaft on a vehicle that has a 5 hp output. Do you think you could put 10 hp through it and not twist that driveshaft apart? No, you would probably need a 1/2 inch driveshaft to withstand that extra torque no matter what differential it is connected to.

He said he was breaking the 1/2" adapters, so the weak point is the 1/4" shaft with the 1/2" end on it.

See @Methane Herder ’s reply above.

Last edited:

Someone get the lights.

Someone get the lights.