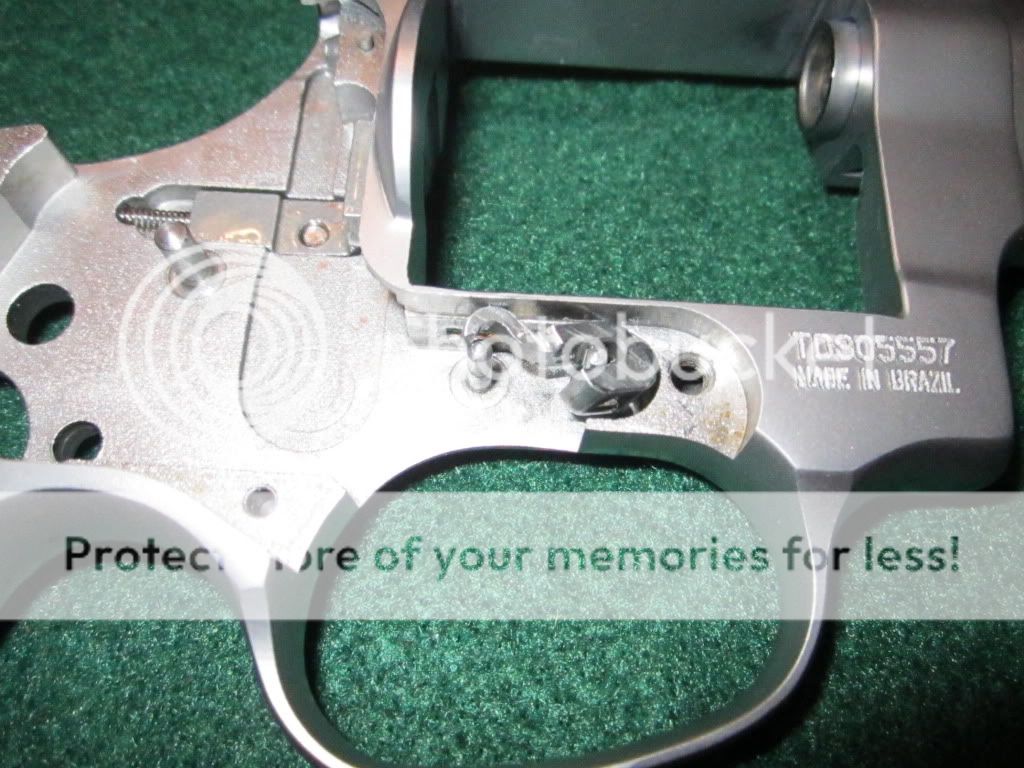

These two photos kind of show the bafore-and-after polishing of the sides of the trigger. The first right side is the dull "bead-blasted" finish from the manufacturer and the second picture shows the left side when I was done with it. The finished side actually shows the clear reflection of the workmat in it! The entire trigger looks like this.

Just be meticulous with everything you do, buy the right tools, buy good parts and take your time.

Just be meticulous with everything you do, buy the right tools, buy good parts and take your time.