Caveat Primer:

As a gun owner, recreational shooter and shooting sports enthusiast, I enjoy doing just about anything shooting-related with friends or with family. I can’t imagine anything more productive, educational and rewarding than teaching someone else how to properly handle a firearm for their own enjoyment or protection, including how to service the gun they may ultimately own for themselves.

The catch for most folks (especially me) is that we’re not all gunsmiths to know everything there is to know about the mechanical aspects of a gun, yet we may need or want to modify our guns to do whatever we want, for the purpose we want- without having to spend the coin or time to have our guns serviced by a professional gunsmith. Translation- I like to tackle the minor stuff myself.

That said, I’m certainly NOT minimizing the expertise and abilities of a Professional Gunsmith in their field, nor the costs they charge, because in all likelihood, they are typically very good at what they do, they often charge prices that are commiserate with the services they offer and sometimes- a Pro Gunsmith is just what a guy really needs to get the job done right on their gun. In other words, I respect them greatly and wish I knew half of what they have forgotten!

As a DIY’er, *I LOVE* to take on a task or challenge that I know nothing about, because the research needed to get to the point of actually doing the work is half the fun, where after I’m done, I’m wiser about the subject than before I started- whether the project went good or bad.

I’m thankful God blessed me with a good mechanical aptitude, a garage full of professional tools and I’m proficient in using them. I’m a mechanical engineer by profession and perform basic manual machining/MIG-TIG welding operations for myself. I’ve done a LOT of stuff in my 40 years, so I guess I’m kind of a “jackazz of all trades”.

However, I’m probably just like most anyone else who owns guns; I certainly don’t know everything about even the guns I have, much less on to service them mechanically, so if the work they need is something I think I can handle, I’ll try to do it myself- if for nothing else but to learn how my stuff works.

I’d bet that most folks’ who can field strip a gun or reload their own ammo can most likely do the minor stuff the pros do, we just need a little guidance on how to do the job and use common sense in doing so. In other words, if you’re good with your hands, you can likely become a proficient DIY’er gunsmith for your own stuff.

As a caveat- I’m no gun expert and I’m not a Gunsmith. The improvements or upgrades I do to my guns, I do so with full knowledge that I might muck something up, making the thing unusable, so I never do anything I’m not comfortable with or don’t have the tools to do them. Heck, the real pro’s may not even call what I’m doing “gunsmithing”, but whatever you want to call it, the mods DO make the gun more reliable, perform better and shoot more accurately, which is what my intended goals are.

Everyone’s ability is different and if the mods you see me post here isn’t what YOU feel comfortable with, than by all means DON’T DO IT! However, if you’d like to take the job on yourself, I can tell you that it’s very rewarding in the end to know you’ve done the work yourself, where the gun now means more than ever before, because a part of you is now in it. Plus, it’s just a boat-load lot of fun!!

Please feel free to ask questions & leave comments, as there are some extremely knowledgeable people on here who will likely be happy to help answer questions and/or correct me if I error.

I hope you find this thread informative & helpful. It’s been fun putting it together.

Here we go!

As a gun owner, recreational shooter and shooting sports enthusiast, I enjoy doing just about anything shooting-related with friends or with family. I can’t imagine anything more productive, educational and rewarding than teaching someone else how to properly handle a firearm for their own enjoyment or protection, including how to service the gun they may ultimately own for themselves.

The catch for most folks (especially me) is that we’re not all gunsmiths to know everything there is to know about the mechanical aspects of a gun, yet we may need or want to modify our guns to do whatever we want, for the purpose we want- without having to spend the coin or time to have our guns serviced by a professional gunsmith. Translation- I like to tackle the minor stuff myself.

That said, I’m certainly NOT minimizing the expertise and abilities of a Professional Gunsmith in their field, nor the costs they charge, because in all likelihood, they are typically very good at what they do, they often charge prices that are commiserate with the services they offer and sometimes- a Pro Gunsmith is just what a guy really needs to get the job done right on their gun. In other words, I respect them greatly and wish I knew half of what they have forgotten!

As a DIY’er, *I LOVE* to take on a task or challenge that I know nothing about, because the research needed to get to the point of actually doing the work is half the fun, where after I’m done, I’m wiser about the subject than before I started- whether the project went good or bad.

I’m thankful God blessed me with a good mechanical aptitude, a garage full of professional tools and I’m proficient in using them. I’m a mechanical engineer by profession and perform basic manual machining/MIG-TIG welding operations for myself. I’ve done a LOT of stuff in my 40 years, so I guess I’m kind of a “jackazz of all trades”.

However, I’m probably just like most anyone else who owns guns; I certainly don’t know everything about even the guns I have, much less on to service them mechanically, so if the work they need is something I think I can handle, I’ll try to do it myself- if for nothing else but to learn how my stuff works.

I’d bet that most folks’ who can field strip a gun or reload their own ammo can most likely do the minor stuff the pros do, we just need a little guidance on how to do the job and use common sense in doing so. In other words, if you’re good with your hands, you can likely become a proficient DIY’er gunsmith for your own stuff.

As a caveat- I’m no gun expert and I’m not a Gunsmith. The improvements or upgrades I do to my guns, I do so with full knowledge that I might muck something up, making the thing unusable, so I never do anything I’m not comfortable with or don’t have the tools to do them. Heck, the real pro’s may not even call what I’m doing “gunsmithing”, but whatever you want to call it, the mods DO make the gun more reliable, perform better and shoot more accurately, which is what my intended goals are.

Everyone’s ability is different and if the mods you see me post here isn’t what YOU feel comfortable with, than by all means DON’T DO IT! However, if you’d like to take the job on yourself, I can tell you that it’s very rewarding in the end to know you’ve done the work yourself, where the gun now means more than ever before, because a part of you is now in it. Plus, it’s just a boat-load lot of fun!!

Please feel free to ask questions & leave comments, as there are some extremely knowledgeable people on here who will likely be happy to help answer questions and/or correct me if I error.

I hope you find this thread informative & helpful. It’s been fun putting it together.

Here we go!

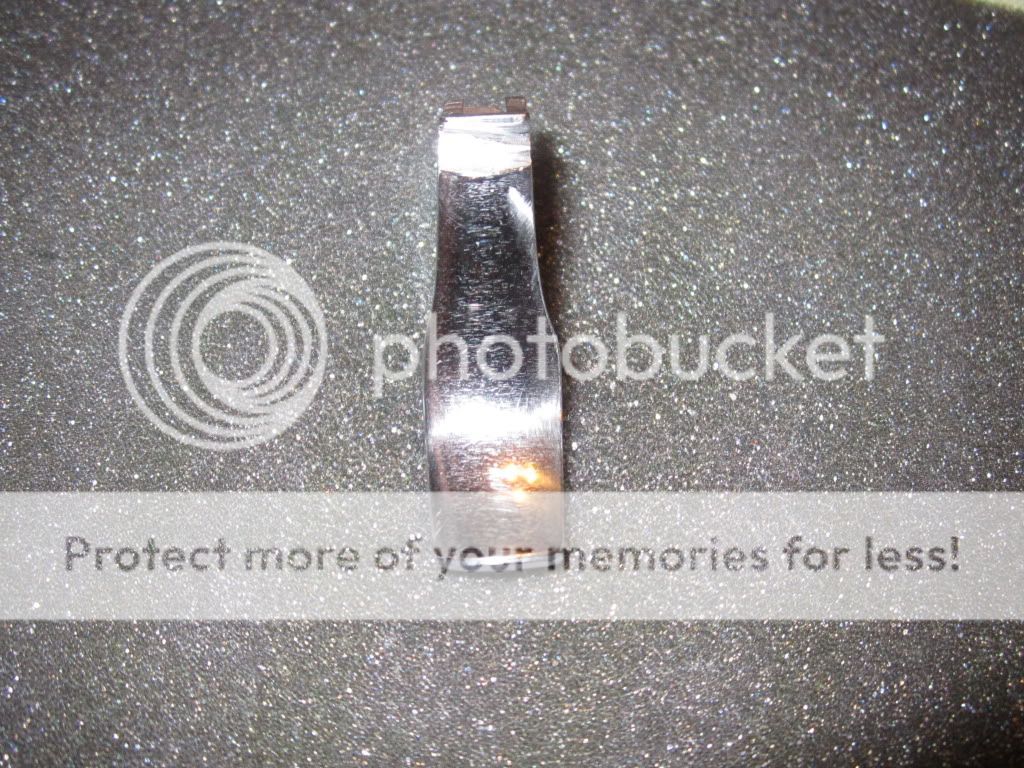

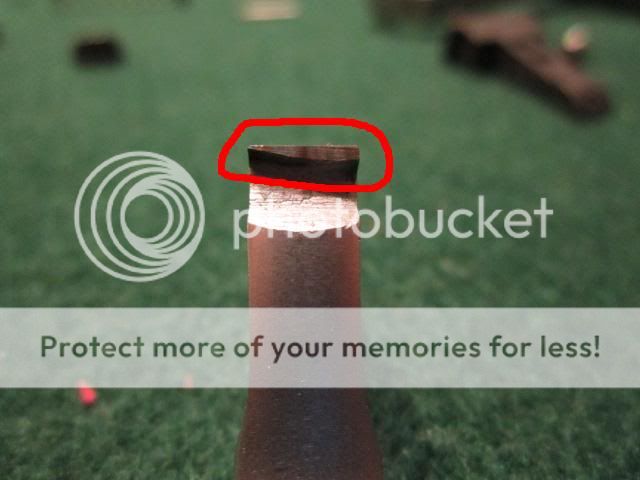

It was in there at some point, as you can clearly see the witness marks left in the spring pockets on the frame and on the sight insert, by the spring itself at some time in the gun's past.

It was in there at some point, as you can clearly see the witness marks left in the spring pockets on the frame and on the sight insert, by the spring itself at some time in the gun's past.

I only have our "point-n-shoot" camera to use and it leaves a lot to be desired in the photo quality department- especially macro and it's always hard to keep the "glare" out of the photos too....

I only have our "point-n-shoot" camera to use and it leaves a lot to be desired in the photo quality department- especially macro and it's always hard to keep the "glare" out of the photos too....