Looking at the next thing, For me it may be a CNC wood router, Anyone have hands on experience with the current offerings. Wanting to do panels for cabinets, and other type wood projects, Not really interested in making pictures of dogs on a 4 inch square, I want to be able to mill out a custom tool box of furniture grade plywood. or similar items. Let me see pics if you have them.

-

Be sure to read this post! Beware of scammers. https://www.indianagunowners.com/threads/classifieds-new-online-payment-guidelines-rules-paypal-venmo-zelle-etc.511734/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CNC routing 4x8 sheet

- Thread starter x10

- Start date

The #1 community for Gun Owners in Indiana

Member Benefits:

Fewer Ads! Discuss all aspects of firearm ownership Discuss anti-gun legislation Buy, sell, and trade in the classified section Chat with Local gun shops, ranges, trainers & other businesses Discover free outdoor shooting areas View up to date on firearm-related events Share photos & video with other members ...and so much more!

Member Benefits:

A brother has a shaper and I have a 3 1/2 HP Hitachi plunge router for cabinet fronts.Looking at the next thing, For me it may be a CNC wood router, Anyone have hands on experience with the current offerings. Wanting to do panels for cabinets, and other type wood projects, Not really interested in making pictures of dogs on a 4 inch square, I want to be able to mill out a custom tool box of furniture grade plywood. or similar items. Let me see pics if you have them.

I don't own one personally, but a big part of my job is programming CNC machines, including big 3 axis routers. Our routers are all CR Onsrud brand. To my knowledge, they don't really make a consumer grade machine.

How much experience do you have with the CAD/CAM side of machining?

How much experience do you have with the CAD/CAM side of machining?

I've got some experience, but the good news is that there are consumer friendly software out there, were not talking aerospace tolerances.

But from what I'm hearing there are no CNC router owners in the Ingo community. Right now I'm partnering up with a cabinet maker in the area but I'm going to have to find a laser engrave or an small table cnc router to achieve the results I want

But from what I'm hearing there are no CNC router owners in the Ingo community. Right now I'm partnering up with a cabinet maker in the area but I'm going to have to find a laser engrave or an small table cnc router to achieve the results I want

I've had an xCarve 1mx1m for several years now. Gives a cutting area of about 30"x30". Been pleased with it as a hobbyist. Strong enough for light commercial work, but all machines of these types have several downsides.

--Rick

- The aluminum frames aren't as stiff as a commercial steel framed unit. Can drive cutting depth differences in the middle vs edges.

- They use stepper motors, rather than servos. Therefore the machine doesn't know where it is in space. If it jams and misses a step the rest of the cut will be out of place.

- The drive belts can stretch under load/time. Forces light cuts, like no more than 1/8 inch depth at a time.

- bit changes are totally manual and require resetting the zero (height) axis every time.

--Rick

This is exactly the response I was looking for, I'm trying to figure out some things, and I think for right now I'm going to contract out my routing work, at some point that will have to change but jumping into a 10k machine doesn't make good business sense right now, but I'm going to need ID marks and logo's and info, I may fall back on a silk screen process just to get things moving.I've had an xCarve 1mx1m for several years now. Gives a cutting area of about 30"x30". Been pleased with it as a hobbyist. Strong enough for light commercial work, but all machines of these types have several downsides.

I'm not bringing any of these up to diss on the machines. They are very capable if used within the parameters they were made for. However, if you want to toss a full sheet of ply and make 1 pass through cuts like you see factories doing on youtube, this isn't for you.

- The aluminum frames aren't as stiff as a commercial steel framed unit. Can drive cutting depth differences in the middle vs edges.

- They use stepper motors, rather than servos. Therefore the machine doesn't know where it is in space. If it jams and misses a step the rest of the cut will be out of place.

- The drive belts can stretch under load/time. Forces light cuts, like no more than 1/8 inch depth at a time.

- bit changes are totally manual and require resetting the zero (height) axis every time.

--Rick

You say "routing cabinet doors" which can mean a ton of different things. If you are wanting to route the edges of raised panel doors, not gonna happen w/ these machines. However, since you mentioned laser engraver or silk screen, they may work fine. I've made the following on my machine:

Cut the stars from the background, inverse carved inlay stars and glued in place..

https://photos.google.com/album/AF1.../AF1QipOaEyLzrhgzG3f29kGSbsOHV_MqDdyWV4_awgQH

https://photos.google.com/album/AF1.../AF1QipOaEyLzrhgzG3f29kGSbsOHV_MqDdyWV4_awgQH

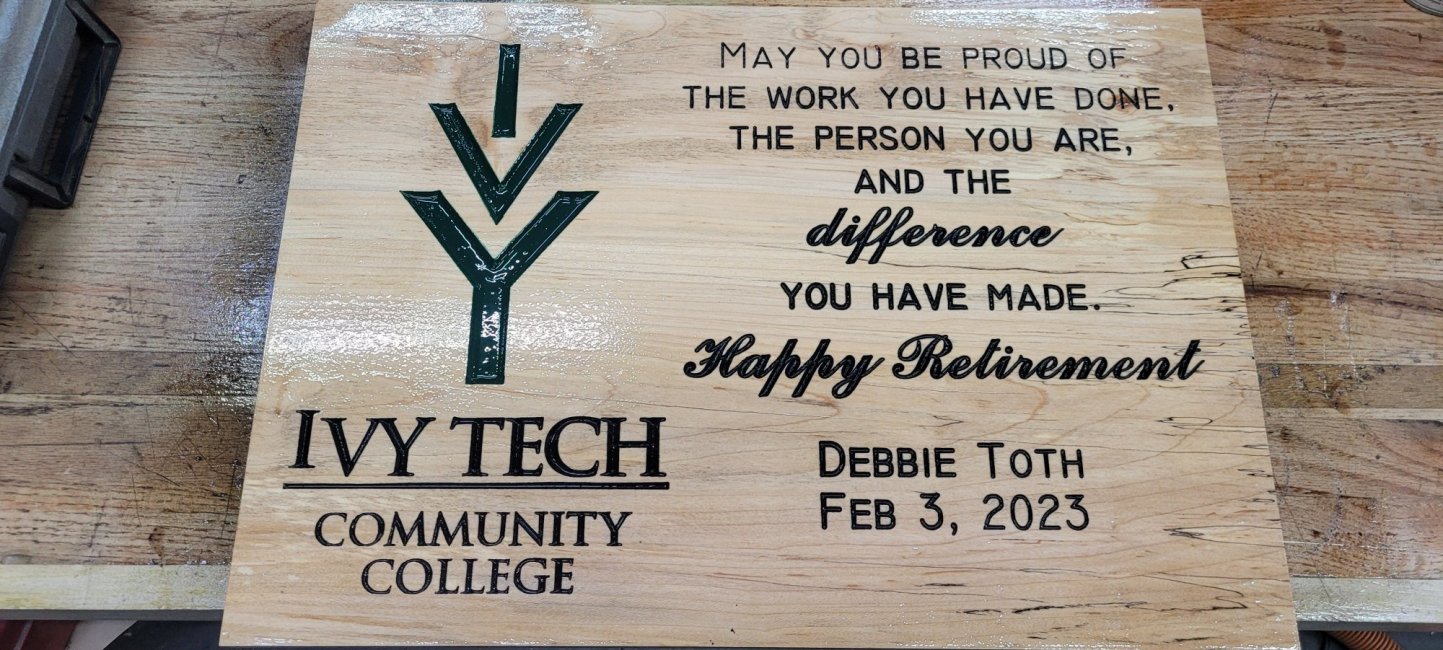

Veneered spalted maple on walnut, then VCarved the words:

https://photos.google.com/album/AF1.../AF1QipOaEyLzrhgzG3f29kGSbsOHV_MqDdyWV4_awgQH

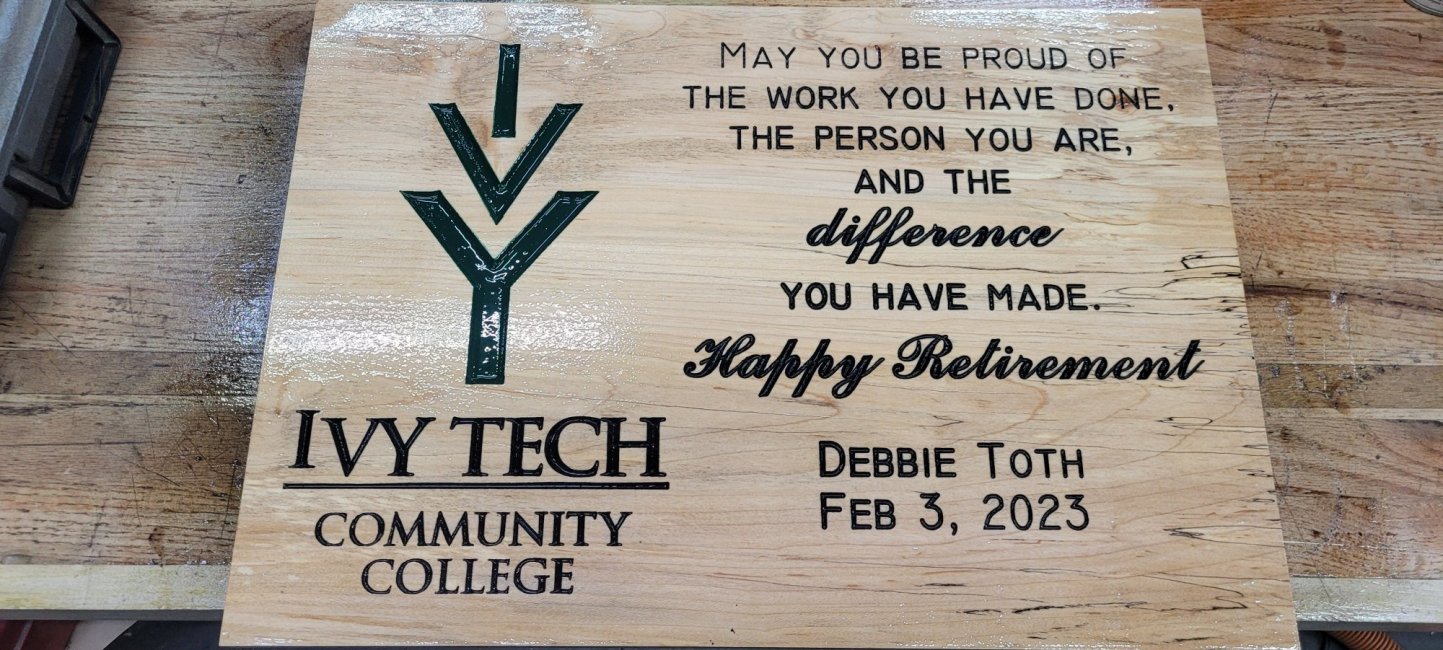

A retirement sign - Being critical, you can see the deflection in middle in the first 2 words at the top.

https://photos.google.com/album/AF1.../AF1QipOaEyLzrhgzG3f29kGSbsOHV_MqDdyWV4_awgQH

Finally, used it for LIGHT machining of a screwed up wheel!

https://photos.google.com/album/AF1.../AF1QipOaEyLzrhgzG3f29kGSbsOHV_MqDdyWV4_awgQH

https://photos.google.com/album/AF1.../AF1QipOaEyLzrhgzG3f29kGSbsOHV_MqDdyWV4_awgQH

Let me know if you'd like to see more or even a demo of what I have.

--Rick

Cut the stars from the background, inverse carved inlay stars and glued in place..

https://photos.google.com/album/AF1.../AF1QipOaEyLzrhgzG3f29kGSbsOHV_MqDdyWV4_awgQH

https://photos.google.com/album/AF1.../AF1QipOaEyLzrhgzG3f29kGSbsOHV_MqDdyWV4_awgQH

Veneered spalted maple on walnut, then VCarved the words:

https://photos.google.com/album/AF1.../AF1QipOaEyLzrhgzG3f29kGSbsOHV_MqDdyWV4_awgQH

A retirement sign - Being critical, you can see the deflection in middle in the first 2 words at the top.

https://photos.google.com/album/AF1.../AF1QipOaEyLzrhgzG3f29kGSbsOHV_MqDdyWV4_awgQH

Finally, used it for LIGHT machining of a screwed up wheel!

https://photos.google.com/album/AF1.../AF1QipOaEyLzrhgzG3f29kGSbsOHV_MqDdyWV4_awgQH

https://photos.google.com/album/AF1.../AF1QipOaEyLzrhgzG3f29kGSbsOHV_MqDdyWV4_awgQH

Let me know if you'd like to see more or even a demo of what I have.

--Rick

Technically, the hobbyist machines are very capable of making raised panel doors, with the correct software and knowledge.You say "routing cabinet doors" which can mean a ton of different things. If you are wanting to route the edges of raised panel doors, not gonna happen w/ these machines. However, since you mentioned laser engraver or silk screen, they may work fine. I've made the following on my machine:

There are several guys, that make MDF doors (that you would never know weren't solid wood) as their business.

As for machines that are capable of cutting 4x8 without tiling, are going to set you back.

CNC isn't inexpensive, and if it's for a business, you will want a welded steel frame, with several amendments.

There are several companies that build capable machines in the size you require, but the prices have gotten crazy.

The one company I was hoping to build my next machine, has eliminated the line I was interested in, and now their entry level machine starts at $34K.

You may want to search the used market, but again, the prices are near new.

A hobbyist machine isn't going to run production quantities, and they all have issues.

Most programs have a trial version, so be sure to give them a try before committing to them.

I love my machine, and can run cabinets all day, but that doesn't interest me. I've done a few, but it's almost as fast using a table saw, shaper, and a couple jigs.

Be prepared for the learning curve.

You say "routing cabinet doors" which can mean a ton of different things. If you are wanting to route the edges of raised panel doors, not gonna happen w/ these machines. However, since you mentioned laser engraver or silk screen, they may work fine. I've made the following on my machine:

Cut the stars from the background, inverse carved inlay stars and glued in place..

https://photos.google.com/album/AF1.../AF1QipOaEyLzrhgzG3f29kGSbsOHV_MqDdyWV4_awgQH

View attachment 293607

https://photos.google.com/album/AF1.../AF1QipOaEyLzrhgzG3f29kGSbsOHV_MqDdyWV4_awgQH

Veneered spalted maple on walnut, then VCarved the words:

View attachment 293608

https://photos.google.com/album/AF1.../AF1QipOaEyLzrhgzG3f29kGSbsOHV_MqDdyWV4_awgQH

A retirement sign - Being critical, you can see the deflection in middle in the first 2 words at the top.

View attachment 293615

https://photos.google.com/album/AF1.../AF1QipOaEyLzrhgzG3f29kGSbsOHV_MqDdyWV4_awgQH

Finally, used it for LIGHT machining of a screwed up wheel!

View attachment 293616

https://photos.google.com/album/AF1.../AF1QipOaEyLzrhgzG3f29kGSbsOHV_MqDdyWV4_awgQH

https://photos.google.com/album/AF1.../AF1QipOaEyLzrhgzG3f29kGSbsOHV_MqDdyWV4_awgQH

Let me know if you'd like to see more or even a demo of what I have.

--Rick

I would love to see some demo vids, this is turning into a great thread. One of my goals is to somehow etch/mill/laser/??? a logo/company name/ visual enhancement into a panel

Staff online

-

d.kaufmanStill Here

Members online

- Matt 22

- Tankerdave

- Gravyman

- fullauto 45

- Rebel Jack

- clelaj

- 63PGP

- Blazer90

- tomcat13

- d.kaufman

- Larry!!!

- cute_rascal

- Gaffer

- hoosier88

- Snapdragon

- Tom Threetoes

- DoggyDaddy

- bigretic

- mkgr22

- wtburnette

- rhamersley

- LeftyGunner

- Malware

- ghunter

- Destro

- DDadams

- Dutchmaster

- Mongo59

- Jmtbug21

- TacOpsGuy320

- Kirk Freeman

- efd1295

- renauldo

- TLHelmer

- sumphead

- prentman

- spencer rifle

- BeDome

- Ark

- red_zr24x4

- m82mike

- opus1776

- BigBoxaJunk

- ghuns

- Itchytriggerfinger

- crookcountygo

- medavis428@

- mmpsteve

- Cavman

- OneBadV8

Total: 1,699 (members: 198, guests: 1,501)