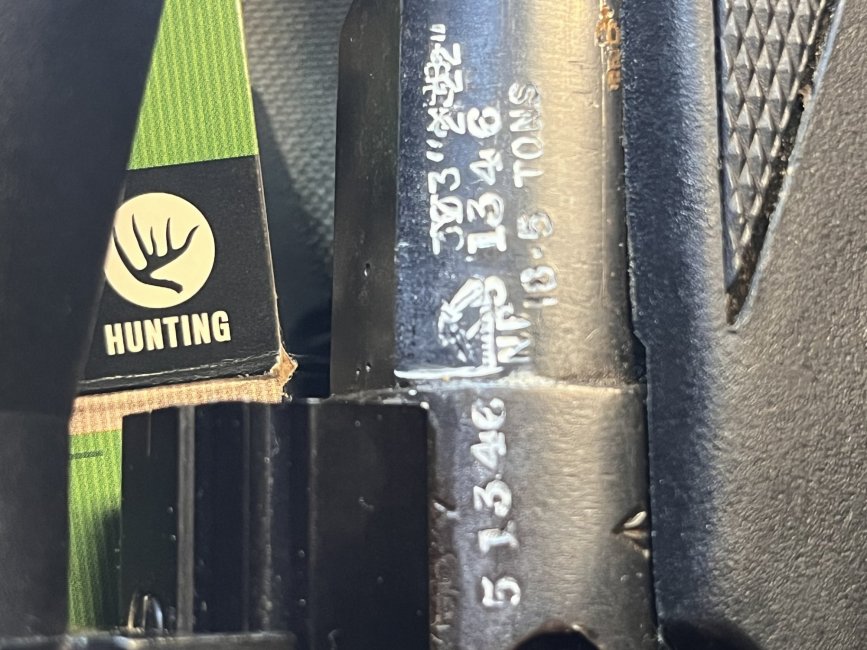

Bought a SMLE no1 mkIII for my son. everything works well BUT a couple of rounds, .303 British, were split around the base. It had a headspace gauge on it but......

Also the person I bought it from thought but was not certain, it may have been rechambered in .308. Did not find any proof there.

From what I have read and researched it may be a headspace issue. Looking for a gunsmith or experienced Lee Enfield person to help out. Thoughts and advice are appreciated.

PM me please if you are gunsmith familiar with Enfields, Thank you.

Also the person I bought it from thought but was not certain, it may have been rechambered in .308. Did not find any proof there.

From what I have read and researched it may be a headspace issue. Looking for a gunsmith or experienced Lee Enfield person to help out. Thoughts and advice are appreciated.

PM me please if you are gunsmith familiar with Enfields, Thank you.

Attachments

Last edited: