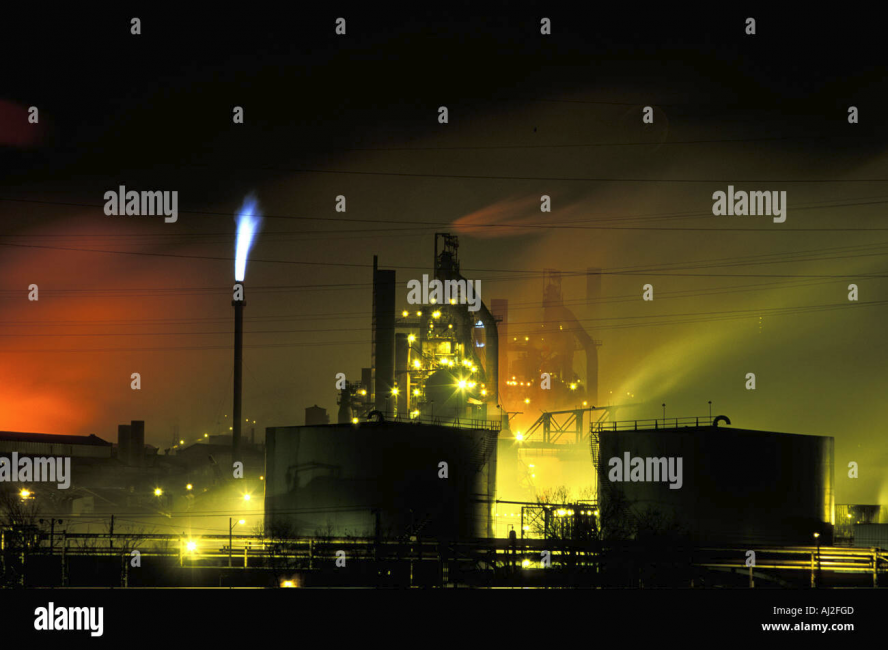

Power outage at BP oil refinery in Indiana prompts evacuation, temporary shutdown

Authorities say BP's sprawling oil refinery in northwest Indiana was hit by a power outage that prompted the company to shut it down and evacuate workers.

www.newsday.com

Drove by there this morning taking my brother to the University of Chicago hospital. Glad we missed that mess.