This is going to be pretty long. Hopefully someone reads it. I wanted to post this to show how I approached it and ask a few questions about the experience so far. I think I’m off to a good start, but have run in to some hiccups and have a few questions. We’ve used the press on three or four different occasions. The first couple times were just playing around with different loads which I’ll detail later. The last two sessions were production runs of about 6,000 rounds each. So we’ve probably loaded about 13 or 14,000 rounds on the press so far. If anyone has comments on the approach or process, or ways to improve, please provide input.

Background

Last year with the ammo price increases and scarcity, my shooting buddy (Jason) and I decided it was time to get in to reloading. We do a big chunk of our practice, training classes, and other shooting activities together. We had considered just going it on our own, and buying presses individually. We thought if we bought a bigger press and tag-teamed it we could put out significant amounts of ammo in short bursts. One person could load primer tubes, keep the case feeder topped off, and QC the ammo as it comes out. We both primarily shoot 9mm and that’s what we’d be reloading.

Neither of us really wanted to reload and are only doing it to save on the cost of ammunition. We want to spend as little time as possible reloading and get as much ammo as we can out of the effort we expend. If we could load three or four times a year and get all the ammo we need, that’s our goal. A few years ago we were each shooting around 10-15k rounds a year on average. It’s definitely on the lower side the last couple years. So 5k to 7k per loading session was the goal. We split the cost of components and split the ammo evenly when we’re finished.

At the time, we decided we could reload for about $0.15 per round of 9mm ammunition based on component prices found online. The prevailing price for a case of brass-cased 9mm ammunition was about $250, or $0.25 per round. So we were figuring our break-even cost at $0.10 per round savings. This is using a plated or jacketed bullet and just whatever prices I found on the internet at the time. I know it can be done cheaper by looking for deals, using lead bullets, etc. Before the most recent price increases I could find cases of 9mm for 20 cents a round and it just wasn’t worth it to reload. After the price increases the savings went up to $0.10 or better and it started to look more attractive. (Of course, the prices of cased ammo are coming back down. So that’s cutting in to the B/E analysis.) Here’s what I found for current component prices with a quick search (we’ve been buying brass locally for around $0.03-0.035 per round and assume about a 40-50% pickup rate):

We had looked at three different press setups: The Hornady Lock n Load, the Dillon 650, and the Dillon 1050. I have still never really seen the Hornady fully set up and in use. INGO user (Fourtrax) was kind enough to show me his Dillon 650 when he invited me over to shoot. For a while I thought we were going to get the Dillon 650. At $970 to get set up, it was much cheaper than the Dillon 1050 ($1800.00). I had never actually reloaded on any of them, or any press for that matter.

Then I found Aszerigan selling a used Dillon 1050 at Profire and decided to go big or go home. I got the 1050, powder scale, calipers, case gauge, a partial jug of titegroup powder (maybe 2 or 3lbs), 9mm brass left in the case feeder, primer tubes, and some other odds n ends for around 1800 bucks out the door. It seemed like a good deal at the time. The 1050 was attractive to me for two reasons. First, the priming on the down stroke seems like it would be faster and more consistent. Secondly, the tool head moves up and down rather than moving the shell plate. This just seems like it would be smoother. While I haven’t used a 650 or a Hornady enough to be sure that’s the case, it seems likely. Other online discussions and reviews seem to indicate this as well. I am convinced the LnL or 650 could be almost as fast, if not just as fast as a 1050, but we were hoping for smooth, event-free operations out of the 1050. I am figuring about 20,000 rounds to break even on the press and other start-up costs.

The Setup

I’ll throw a few pics of the setup in here for fun. I keep the press at my house and want it to take up as little space as possible when it’s not in use. No reloading rooms or permanent setups. I mounted the press to a rolling cabinet. When it’s time to load I set up a folding table and put some boards across saw horses. When we’re done I break it down and roll the cabinet in to the corner of the garage. The ergonomics of this setup really kinda suck. The cabinet is just a few inches too short to be comfortable operating the press for several hours at a time. So this may change in the future.

Load Development

We really didn’t know where to start here. So we started gathering as much data as we could. Probably more than we needed. Then we began looking at and testing different loads using the Titegroup supplied with the press. We also tried a couple other powders (700X, 4756, and Rex) but we like the Titegroup the best. We are hoping to find one good load and just run it as long as those components are available.

We started with a couple reloading manuals and got the following info:

From Modern Reloading; Second Edition by Richard Lee 2003

From the Lyman Reloading Handbook 49[SUP]th[/SUP] ed

And then from the Hodgdon Website

We also measured and chronographed some factory ammunition we each had laying around. We wanted to see what kind of velocity we were getting from the ammo we were already using. We also wanted to see what kind of OAL this stuff had to get a baseline. The sample sizes are fairly small. Most of it was pulled from mixed cans. We’d been dumping new ammo in them and taking it to the range. So we dug around and pulled out as many different head stamps as we could fine. Aguila and Remington seemed to be shorter than the others. Of the 6 brands, 4 had an OAL around 1.15”. This was longer than quoted in the reloading manuals above. So we assume the reloading manuals were giving the minimum. I still don’t think we’ve determined what is optimal, or even know how to determine that.

Based on the above we started on the low side of the powder and the long side of OAL just to be safe. Our first batch was 10 rounds at 3.8gr of Titegroup at an average 1.16” OAL. This was similar to the WWB OAL, but the powder was so low it barely cycled. We had an average velocity of 971fps. We played around a bit more with different charges and lengths to see how that would affect the velocity.

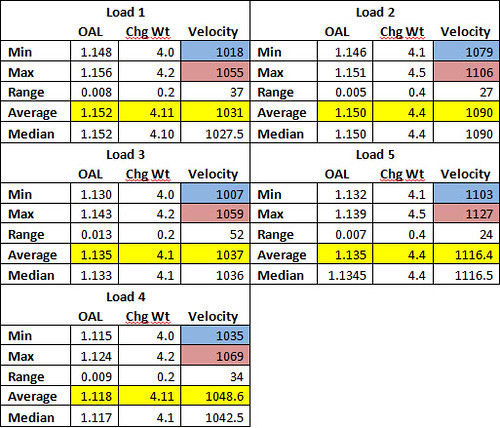

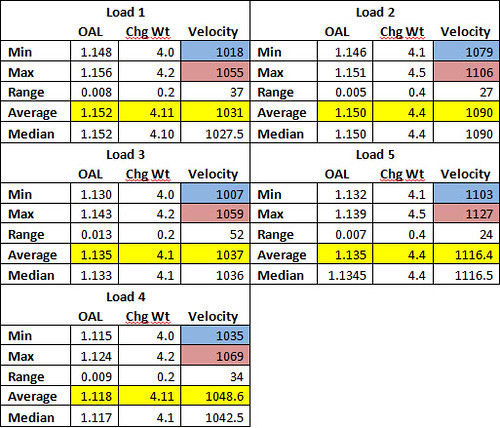

The chart below is a sampling of those results as we got closer to the goal. Each chart represents a sample of 10. Our first production run (~6k rnds) was based on load 2. The second production run was based on load 5. We shortened it up a bit because I have noticed some infrequent feeding issues. I am wondering if the length could be a contributor. This pushed the velocity consistently up over 1100. If anyone can comment on the 9mm OAL they are using that would be helpful.

Production

After we had a load developed, we decided to move into mass production. We basically run it as outlined in the background section. One guy operates the press while the other does everything else like load primer tubes, lube brass, gauge and inspect the ammo as it comes out, etc. We switch off every thousand rounds or so. Then we sort the ammo in to trays from factory ammo boxes, visually inspect the primers and look for any abnormal lengths or anything that looks funny. The trays help us give them a good visual inspection and also help with counting for splitting the ammo.

This will probably seem like huge overkill, but I wanted to get an idea what kind of repeatability we were getting from the press. I started keeping a run chart showing in-process measurements of OAL and powder charge. We tend to take one measurement for powder and OAL in every one or two primer tubes. So around 60 or 70 measurements in a 6k production run. This gives us some data to trend and see how things are running. Since we’re new at reloading and trying to do relatively large volumes quickly, we want to identify any problems before we make a whole batch of bad ammo.

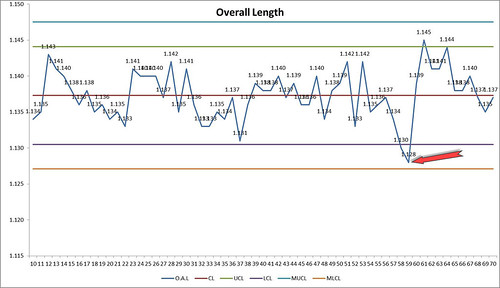

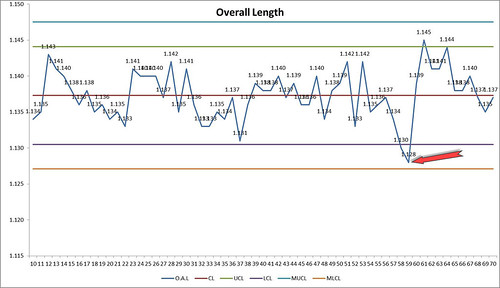

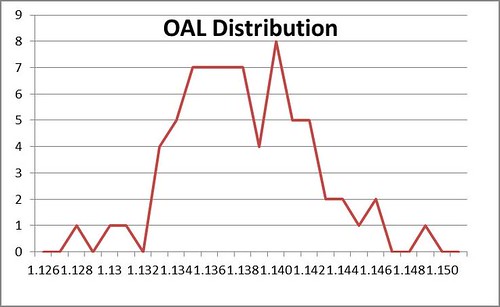

Below is the overall length measurements. If there are any quality engineers readings this, I know this probably isn’t a proper run chart, but it’s the best I could do. The chart shows 60 measurements numbered 10 to 70 (the first 10 were some early adjustments). The measurements have an average OAL of 1.137 (min 1.128, max 1.145, range .017, std dev .0034).

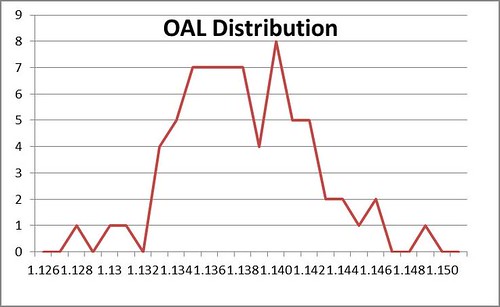

Note around measurement 60 (marked by the red arrow) there is a low trend and then a jump to the high side. We noticed this trend and took the die out to clean and adjust it. That brought the measurements back in line around the average. I also put up a distribution chart of the measurements. While not a perfect curve, it approximates a normal distribution.

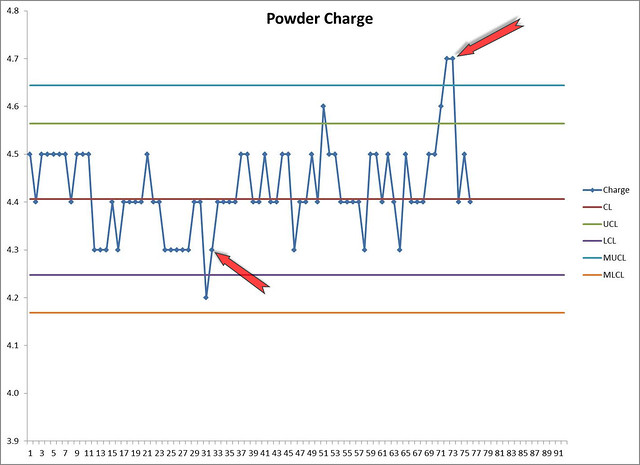

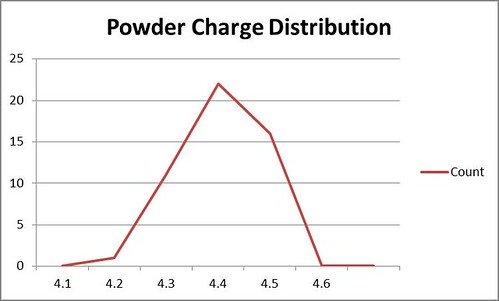

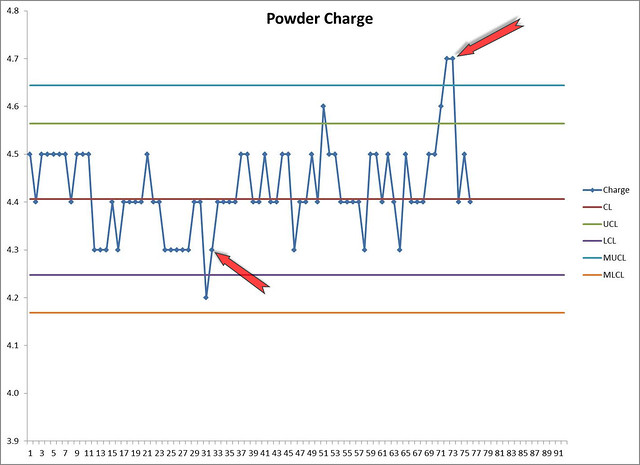

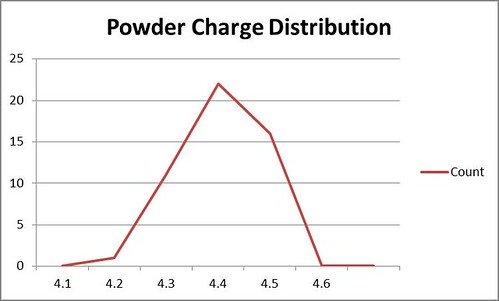

We run the same thing for the powder. The below charts show 76 measurements throughout the production. The distribution is pretty normal, and leans a little to the high side. The average (and target) was 4.4. (min 4.2, max 4.5, range 0.3, std dev 0.079). We made adjustments at two points. The first was around measurement 33 after it had trended low for several measurements then dropped below the control limit. Then around measurement 73 where it jumps up across the maximum upper control limit.

We aren’t certain what lead to the second change. I believe we switched powder lots (finished one 8lb jug and switched over to a 1lb bottle) just before this. It was the same powder, of course, but there could have been some difference in how it metered. The first change was too early in the production for me to remember if anything might have affected the measurements. The scale we are using is only precise to 0.1. So we notice the changes in trends and relatively big jumps.

Issues We’ve Had

The biggest and most prevalent problem we’ve encountered so far is depriming. We couldn’t figure out what was happening at first, but cases were making it around to the swaging and/or priming stations with spent primers still in the pocket. After some reading and observation of the press we determined the primers were riding the decapping pin back in to the primer pocket. They would then move around to the swaging station and get smashed back in to the primer hole.

When it first started happening we weren’t smooth enough to catch it by feel and it would sometimes move to the priming station which would seriously jam up the press. After some experience we knew to watch closely for the primer and when it didn’t fall out we would have to take the brass out and check it. We also learned to feel it at the swaging station better and pull it out if it got to that point. This reduced jams but seriously impacted production rates. We were probably having this issue at least five times for every hundred rounds. We probably loaded 10K rounds this way before we found what we believe has been a workable solution.

This picture shows what the primer looks like when it gets pulled back in:

I did a little reading online and found that some folks that grind the end of the decapping pin to a point. I did this with one to test out and it seems to have solved or significantly reduced the problem. If anyone has any other thoughts or suggestions on why this happens or how to deal with it, I would really like to hear them.

We had some issues early on with bulged brass not chambering properly. An adjustment to the sizing die seems to have fixed the issue, but we still run every round through a Glock 19 chamber (with the barrel removed from the gun) just to verify. This check process takes a fair amount of time.

Another issue we had early on, and I hear is common, is the primer seating depth. We had a number of high primers in our testing phase (we did a couple 200 round test runs of the production ammo before we went all out). We thought this was a little odd because we understood the press to be set up and running when it was at Profire. Nonetheless, a little adjustment seemed to fix the problem. When troubleshooting this issue we noticed it was more common in some brands of casings than others. I measured primer pockets from casings with different head stamps. Some were up to .005” deeper than others.

We also notice a significant amount of brass shavings/filings on the press after a run. The photo below shows what it looks like after we finish (6K rounds or so). I don’t know if this is typical or if we’re somehow damaging the casings with all this wear. I believe the sizing die is a just a typical Dillon. We also use Dillon case lube. If anyone can comment on the brass residue, I would appreciate it.

The second run also had some issues with the case collator dropping in to the tube. We tightened up the plate and tried to get it adjusted. I’m not sure if it helped.

Thoughts and Conclusions

I still don’t really care for reloading. I think it can be a cost saving measure but not so much as some people seem to claim. I know with lead bullets I could push the cost down, but I shoot factory Glocks. So I need the jacketing or plating. I also believe the cost savings is more significant in other cartridges. .45 ACP for example goes for close to $0.40 per round and can probably be reloaded for $0.20. That is a lot better savings than reloading 9mm.

Reloading is also a time-consuming pain in the rear unless you just enjoy the process. I believe as we continue to refine things it will go smoother and much faster. I expect production run number 3 will be much faster than run 2 (assuming the depriming issue is solved). Without any hiccups I can run a primer tube out in about 5-5.5 minutes. That’s easily 1000 rounds an hour if I can do it consistently. So far, I haven’t been able to do that consistently. Something has always held me up (usually the depriming issue).

As for the Dillon 1050, most people don’t recommend it for a new user. I was brand new to reloading and it’s the only press I’ve ever used. I’ve never used a single stage or a turret. I’ve never used a smaller progressive. Mechanically, the press is not that complicated. I think most people could figure it out. I can’t really compare it to the 650 or Hornady, but other than the depriming issue I’m very happy with it. It seems like this is common enough that Dillon should change the design to fix it. (There was a point where I wanted to smash the crap out of it in a fit of rage over the depriming issue. )

)

Background

Last year with the ammo price increases and scarcity, my shooting buddy (Jason) and I decided it was time to get in to reloading. We do a big chunk of our practice, training classes, and other shooting activities together. We had considered just going it on our own, and buying presses individually. We thought if we bought a bigger press and tag-teamed it we could put out significant amounts of ammo in short bursts. One person could load primer tubes, keep the case feeder topped off, and QC the ammo as it comes out. We both primarily shoot 9mm and that’s what we’d be reloading.

Neither of us really wanted to reload and are only doing it to save on the cost of ammunition. We want to spend as little time as possible reloading and get as much ammo as we can out of the effort we expend. If we could load three or four times a year and get all the ammo we need, that’s our goal. A few years ago we were each shooting around 10-15k rounds a year on average. It’s definitely on the lower side the last couple years. So 5k to 7k per loading session was the goal. We split the cost of components and split the ammo evenly when we’re finished.

At the time, we decided we could reload for about $0.15 per round of 9mm ammunition based on component prices found online. The prevailing price for a case of brass-cased 9mm ammunition was about $250, or $0.25 per round. So we were figuring our break-even cost at $0.10 per round savings. This is using a plated or jacketed bullet and just whatever prices I found on the internet at the time. I know it can be done cheaper by looking for deals, using lead bullets, etc. Before the most recent price increases I could find cases of 9mm for 20 cents a round and it just wasn’t worth it to reload. After the price increases the savings went up to $0.10 or better and it started to look more attractive. (Of course, the prices of cased ammo are coming back down. So that’s cutting in to the B/E analysis.) Here’s what I found for current component prices with a quick search (we’ve been buying brass locally for around $0.03-0.035 per round and assume about a 40-50% pickup rate):

We had looked at three different press setups: The Hornady Lock n Load, the Dillon 650, and the Dillon 1050. I have still never really seen the Hornady fully set up and in use. INGO user (Fourtrax) was kind enough to show me his Dillon 650 when he invited me over to shoot. For a while I thought we were going to get the Dillon 650. At $970 to get set up, it was much cheaper than the Dillon 1050 ($1800.00). I had never actually reloaded on any of them, or any press for that matter.

Then I found Aszerigan selling a used Dillon 1050 at Profire and decided to go big or go home. I got the 1050, powder scale, calipers, case gauge, a partial jug of titegroup powder (maybe 2 or 3lbs), 9mm brass left in the case feeder, primer tubes, and some other odds n ends for around 1800 bucks out the door. It seemed like a good deal at the time. The 1050 was attractive to me for two reasons. First, the priming on the down stroke seems like it would be faster and more consistent. Secondly, the tool head moves up and down rather than moving the shell plate. This just seems like it would be smoother. While I haven’t used a 650 or a Hornady enough to be sure that’s the case, it seems likely. Other online discussions and reviews seem to indicate this as well. I am convinced the LnL or 650 could be almost as fast, if not just as fast as a 1050, but we were hoping for smooth, event-free operations out of the 1050. I am figuring about 20,000 rounds to break even on the press and other start-up costs.

The Setup

I’ll throw a few pics of the setup in here for fun. I keep the press at my house and want it to take up as little space as possible when it’s not in use. No reloading rooms or permanent setups. I mounted the press to a rolling cabinet. When it’s time to load I set up a folding table and put some boards across saw horses. When we’re done I break it down and roll the cabinet in to the corner of the garage. The ergonomics of this setup really kinda suck. The cabinet is just a few inches too short to be comfortable operating the press for several hours at a time. So this may change in the future.

Load Development

We really didn’t know where to start here. So we started gathering as much data as we could. Probably more than we needed. Then we began looking at and testing different loads using the Titegroup supplied with the press. We also tried a couple other powders (700X, 4756, and Rex) but we like the Titegroup the best. We are hoping to find one good load and just run it as long as those components are available.

We started with a couple reloading manuals and got the following info:

From Modern Reloading; Second Edition by Richard Lee 2003

| 115 Gr Lead | � | ||||||

| Powder | Start Gr | Vel | N/E | Vel | Press | Units | Min OAL |

| Titegroup | 3.9 | 1075 | 4.3 | 1151 | 30500 | CUP | 1.1 |

From the Lyman Reloading Handbook 49[SUP]th[/SUP] ed

| 115gr JHP | 1.090 OAL | � | ||||

| Powder | Start | Vel | Pressure | Max | Vel | Pressure |

| Titegroup | 4.0 | 1046 | 27,100 | 4.5 | 1119 | 31,400 |

And then from the Hodgdon Website

| 115gr JHP | 1.125 oal | |||||

| Powder | start | vel | Pressure | max | vel | Pressure |

| Titegroup | 4.5 | 1135 | 29500 | 4.8 | 1158 | 30500 |

| 115gr LRN | 1.100 OAL | � | ||||

| Titegroup | 3.9 | 1075 | 25800 | 4.3 | 1151 | 30500 |

We also measured and chronographed some factory ammunition we each had laying around. We wanted to see what kind of velocity we were getting from the ammo we were already using. We also wanted to see what kind of OAL this stuff had to get a baseline. The sample sizes are fairly small. Most of it was pulled from mixed cans. We’d been dumping new ammo in them and taking it to the range. So we dug around and pulled out as many different head stamps as we could fine. Aguila and Remington seemed to be shorter than the others. Of the 6 brands, 4 had an OAL around 1.15”. This was longer than quoted in the reloading manuals above. So we assume the reloading manuals were giving the minimum. I still don’t think we’ve determined what is optimal, or even know how to determine that.

| Velocity | � | |||||

| Blazer Brass | Win White Box | Freedom Reman | Federal Bulk | Remington UMC | Aguila | |

| Sample Size | 10 | 8 | 10 | 5 | 5 | 5 |

| Min | 1015 | 1100 | 1072 | 1078 | 1043 | 1027 |

| Max | 1061 | 1175 | 1107 | 1117 | 1084 | 1072 |

| Range | 46 | 75 | 35 | 39 | 41 | 45 |

| Average | 1040.9 | 1143.5 | 1086.8 | 1101 | 1070.8 | 1047.8 |

| Median | 1042 | 1149 | 1087 | 1109 | 1073 | 1042 |

| Std. Dev | 12.4137 | 26.3764 | 11.02321 | 16.04681 | 16.42255 | 17.71158 |

| Overall Length | � | |||||

| Blazer Brass | Win White Box | Freedom Reman | Federal Bulk | Remington UMC | Aguila | |

| Sample Size | 10 | 8 | 10 | 5 | 5 | 5 |

| Min | 1.148 | 1.155 | 1.146 | 1.146 | 1.094 | 1.105 |

| Max | 1.151 | 1.163 | 1.155 | 1.150 | 1.110 | 1.110 |

| Range | 0.003 | 0.008 | 0.009 | 0.004 | 0.016 | 0.005 |

| Average | 1.149 | 1.160 | 1.151 | 1.148 | 1.107 | 1.107 |

| Median | 1.150 | 1.160 | 1.152 | 1.148 | 1.110 | 1.106 |

| Std. Dev | 0.000966 | 0.002925 | 0.003048 | 0.001789 | 0.00705691 | 0.002168 |

Based on the above we started on the low side of the powder and the long side of OAL just to be safe. Our first batch was 10 rounds at 3.8gr of Titegroup at an average 1.16” OAL. This was similar to the WWB OAL, but the powder was so low it barely cycled. We had an average velocity of 971fps. We played around a bit more with different charges and lengths to see how that would affect the velocity.

The chart below is a sampling of those results as we got closer to the goal. Each chart represents a sample of 10. Our first production run (~6k rnds) was based on load 2. The second production run was based on load 5. We shortened it up a bit because I have noticed some infrequent feeding issues. I am wondering if the length could be a contributor. This pushed the velocity consistently up over 1100. If anyone can comment on the 9mm OAL they are using that would be helpful.

Production

After we had a load developed, we decided to move into mass production. We basically run it as outlined in the background section. One guy operates the press while the other does everything else like load primer tubes, lube brass, gauge and inspect the ammo as it comes out, etc. We switch off every thousand rounds or so. Then we sort the ammo in to trays from factory ammo boxes, visually inspect the primers and look for any abnormal lengths or anything that looks funny. The trays help us give them a good visual inspection and also help with counting for splitting the ammo.

This will probably seem like huge overkill, but I wanted to get an idea what kind of repeatability we were getting from the press. I started keeping a run chart showing in-process measurements of OAL and powder charge. We tend to take one measurement for powder and OAL in every one or two primer tubes. So around 60 or 70 measurements in a 6k production run. This gives us some data to trend and see how things are running. Since we’re new at reloading and trying to do relatively large volumes quickly, we want to identify any problems before we make a whole batch of bad ammo.

Below is the overall length measurements. If there are any quality engineers readings this, I know this probably isn’t a proper run chart, but it’s the best I could do. The chart shows 60 measurements numbered 10 to 70 (the first 10 were some early adjustments). The measurements have an average OAL of 1.137 (min 1.128, max 1.145, range .017, std dev .0034).

Note around measurement 60 (marked by the red arrow) there is a low trend and then a jump to the high side. We noticed this trend and took the die out to clean and adjust it. That brought the measurements back in line around the average. I also put up a distribution chart of the measurements. While not a perfect curve, it approximates a normal distribution.

We run the same thing for the powder. The below charts show 76 measurements throughout the production. The distribution is pretty normal, and leans a little to the high side. The average (and target) was 4.4. (min 4.2, max 4.5, range 0.3, std dev 0.079). We made adjustments at two points. The first was around measurement 33 after it had trended low for several measurements then dropped below the control limit. Then around measurement 73 where it jumps up across the maximum upper control limit.

We aren’t certain what lead to the second change. I believe we switched powder lots (finished one 8lb jug and switched over to a 1lb bottle) just before this. It was the same powder, of course, but there could have been some difference in how it metered. The first change was too early in the production for me to remember if anything might have affected the measurements. The scale we are using is only precise to 0.1. So we notice the changes in trends and relatively big jumps.

Issues We’ve Had

The biggest and most prevalent problem we’ve encountered so far is depriming. We couldn’t figure out what was happening at first, but cases were making it around to the swaging and/or priming stations with spent primers still in the pocket. After some reading and observation of the press we determined the primers were riding the decapping pin back in to the primer pocket. They would then move around to the swaging station and get smashed back in to the primer hole.

When it first started happening we weren’t smooth enough to catch it by feel and it would sometimes move to the priming station which would seriously jam up the press. After some experience we knew to watch closely for the primer and when it didn’t fall out we would have to take the brass out and check it. We also learned to feel it at the swaging station better and pull it out if it got to that point. This reduced jams but seriously impacted production rates. We were probably having this issue at least five times for every hundred rounds. We probably loaded 10K rounds this way before we found what we believe has been a workable solution.

This picture shows what the primer looks like when it gets pulled back in:

I did a little reading online and found that some folks that grind the end of the decapping pin to a point. I did this with one to test out and it seems to have solved or significantly reduced the problem. If anyone has any other thoughts or suggestions on why this happens or how to deal with it, I would really like to hear them.

We had some issues early on with bulged brass not chambering properly. An adjustment to the sizing die seems to have fixed the issue, but we still run every round through a Glock 19 chamber (with the barrel removed from the gun) just to verify. This check process takes a fair amount of time.

Another issue we had early on, and I hear is common, is the primer seating depth. We had a number of high primers in our testing phase (we did a couple 200 round test runs of the production ammo before we went all out). We thought this was a little odd because we understood the press to be set up and running when it was at Profire. Nonetheless, a little adjustment seemed to fix the problem. When troubleshooting this issue we noticed it was more common in some brands of casings than others. I measured primer pockets from casings with different head stamps. Some were up to .005” deeper than others.

We also notice a significant amount of brass shavings/filings on the press after a run. The photo below shows what it looks like after we finish (6K rounds or so). I don’t know if this is typical or if we’re somehow damaging the casings with all this wear. I believe the sizing die is a just a typical Dillon. We also use Dillon case lube. If anyone can comment on the brass residue, I would appreciate it.

The second run also had some issues with the case collator dropping in to the tube. We tightened up the plate and tried to get it adjusted. I’m not sure if it helped.

Thoughts and Conclusions

I still don’t really care for reloading. I think it can be a cost saving measure but not so much as some people seem to claim. I know with lead bullets I could push the cost down, but I shoot factory Glocks. So I need the jacketing or plating. I also believe the cost savings is more significant in other cartridges. .45 ACP for example goes for close to $0.40 per round and can probably be reloaded for $0.20. That is a lot better savings than reloading 9mm.

Reloading is also a time-consuming pain in the rear unless you just enjoy the process. I believe as we continue to refine things it will go smoother and much faster. I expect production run number 3 will be much faster than run 2 (assuming the depriming issue is solved). Without any hiccups I can run a primer tube out in about 5-5.5 minutes. That’s easily 1000 rounds an hour if I can do it consistently. So far, I haven’t been able to do that consistently. Something has always held me up (usually the depriming issue).

As for the Dillon 1050, most people don’t recommend it for a new user. I was brand new to reloading and it’s the only press I’ve ever used. I’ve never used a single stage or a turret. I’ve never used a smaller progressive. Mechanically, the press is not that complicated. I think most people could figure it out. I can’t really compare it to the 650 or Hornady, but other than the depriming issue I’m very happy with it. It seems like this is common enough that Dillon should change the design to fix it. (There was a point where I wanted to smash the crap out of it in a fit of rage over the depriming issue.

)

)