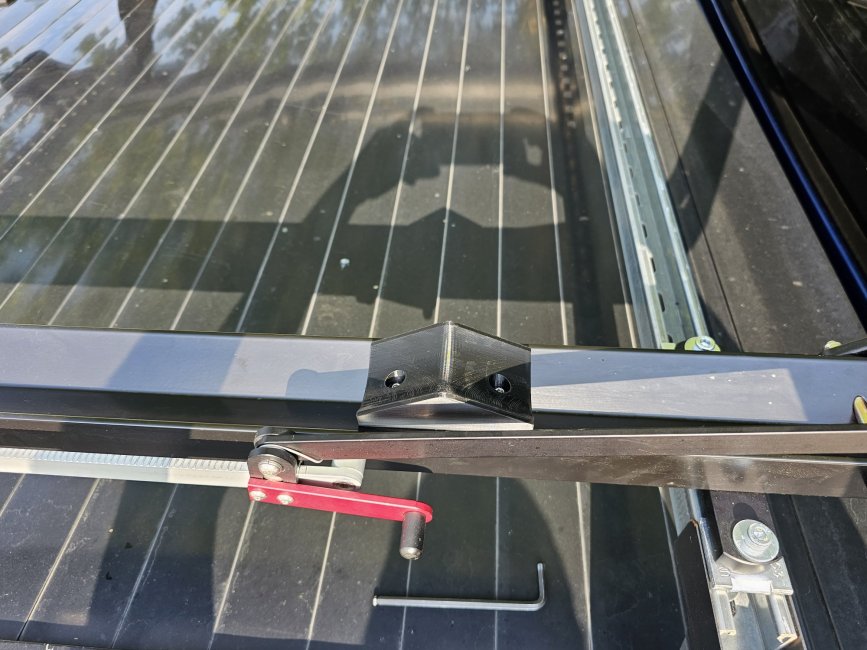

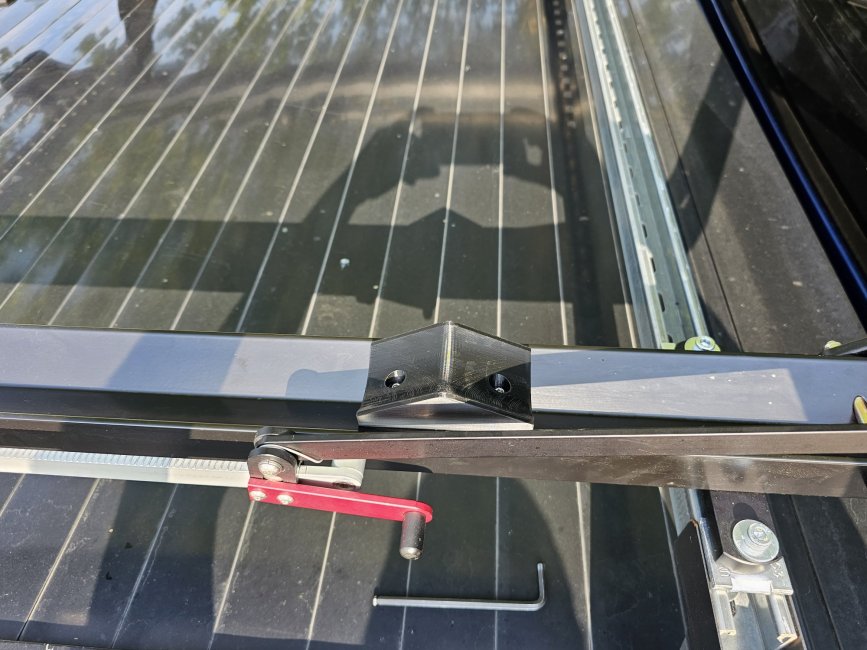

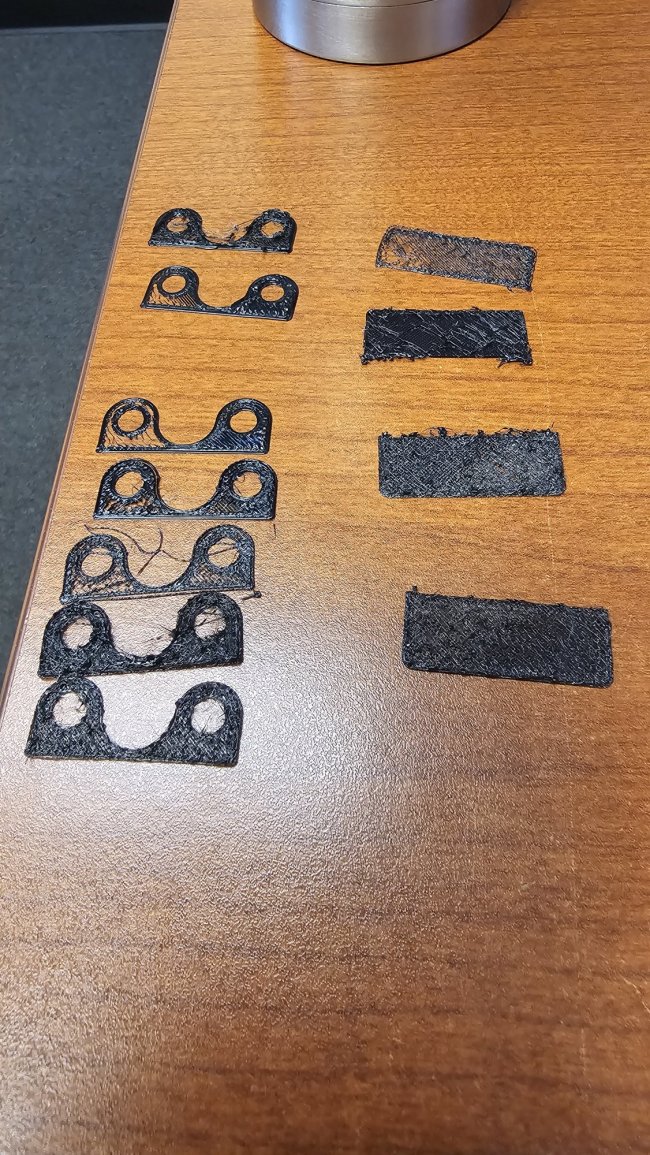

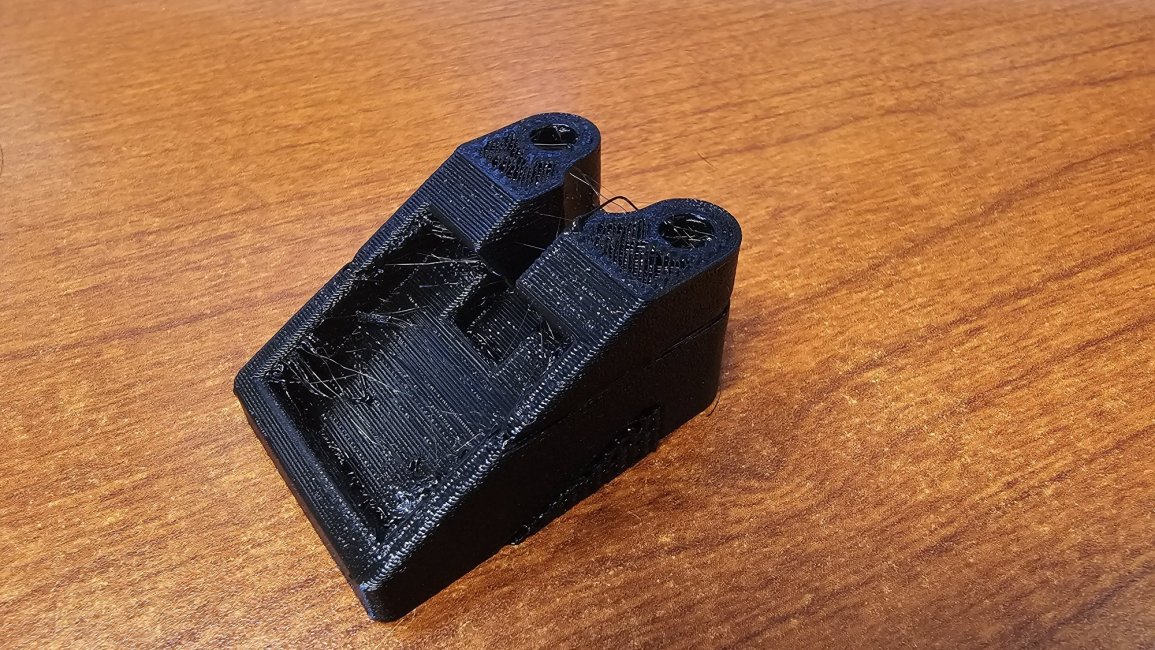

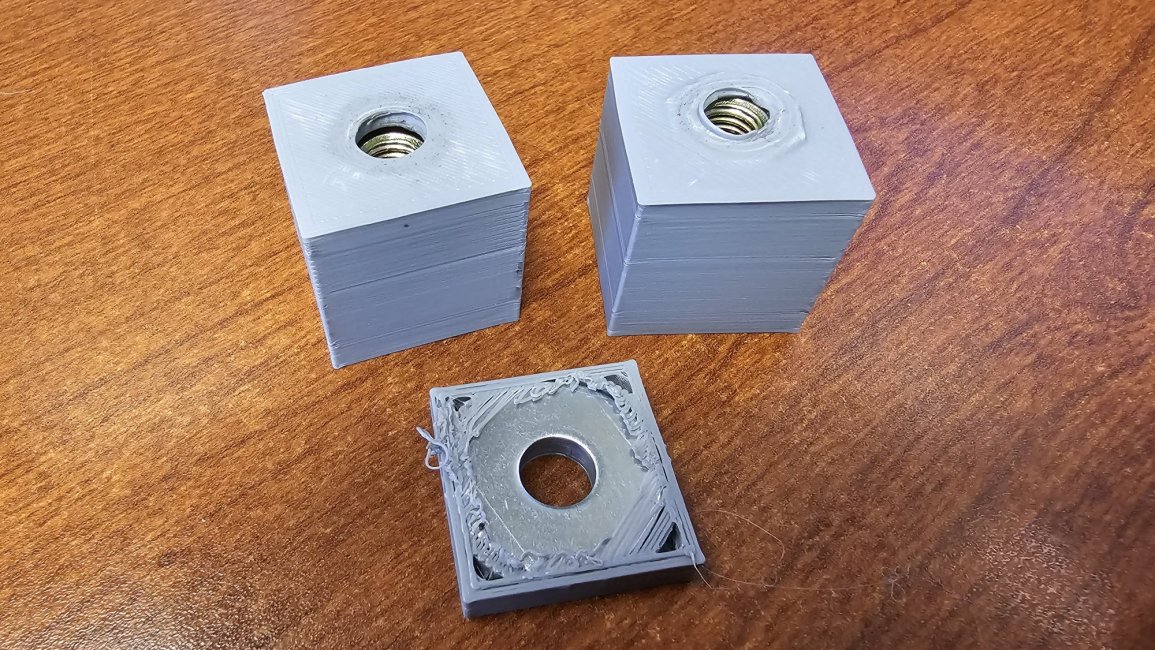

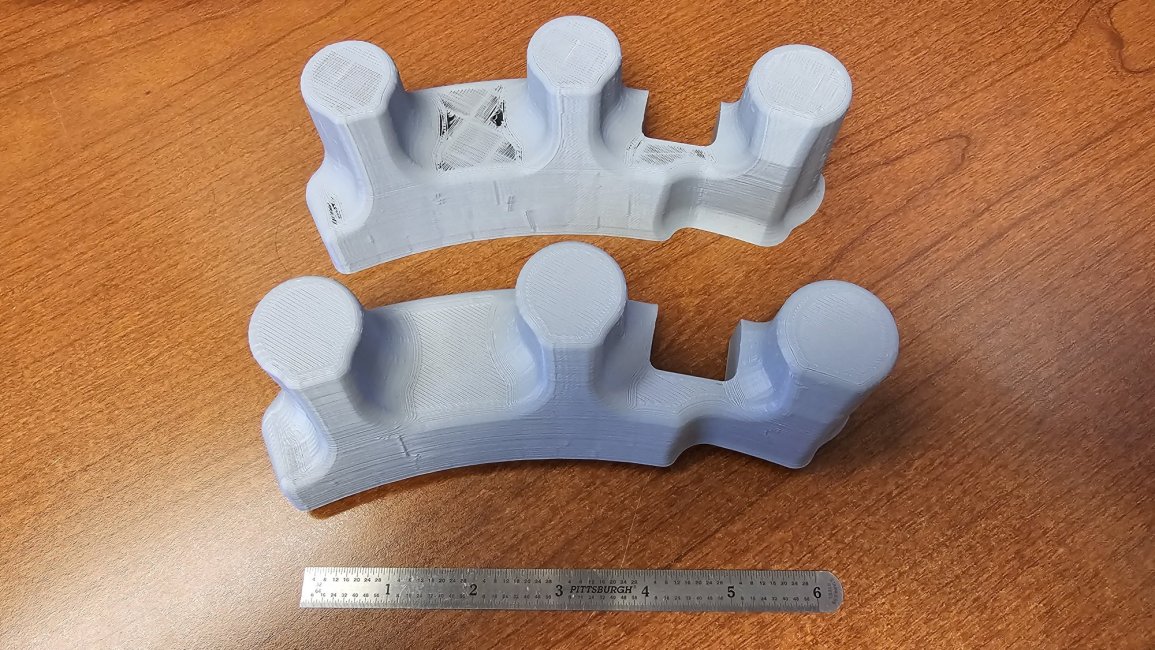

I have two different bike racks on my pickup. They are the same style of rack where they only clamp on the wheels of the bike. One has a wheel chock and the other doesn't. I decided that the one needed a wheel chock to make it easier to center the bike on the rack and make it so the wheel doesn't flop around when driving. Fired up Solidworks and spent a little time designing. Sent it over to the Raise3d printer and hit go. Very happy with the results.