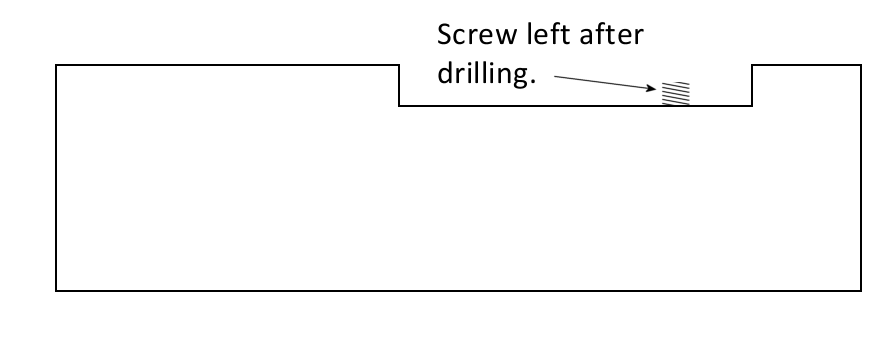

So I bought a TORO upgrade slide for my G3c, and a Vortex Venom red dot. Attempting to install the red dot this morning and 1 of the 2 screws on the optics cover plate must've been installed at the auto dealership with an impact wrench, because I just can't get it to budge.

Any suggestions how to get this screw to break loose?

TIA

Any suggestions how to get this screw to break loose?

TIA