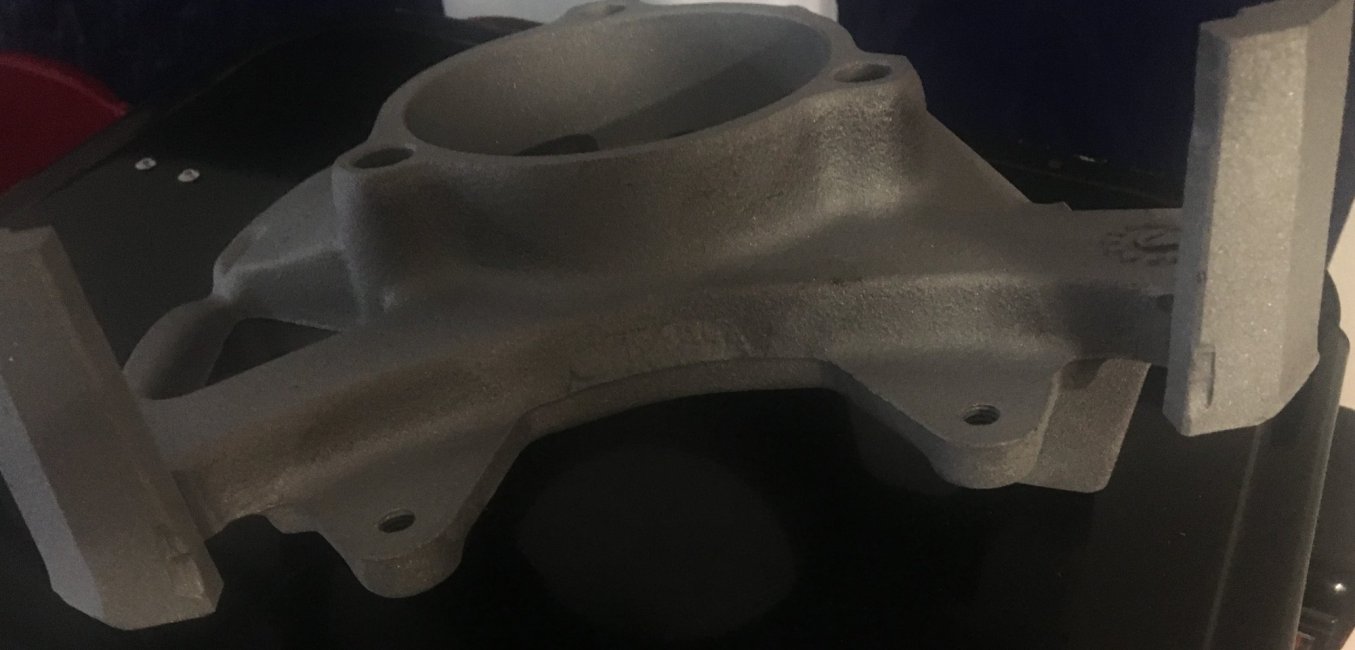

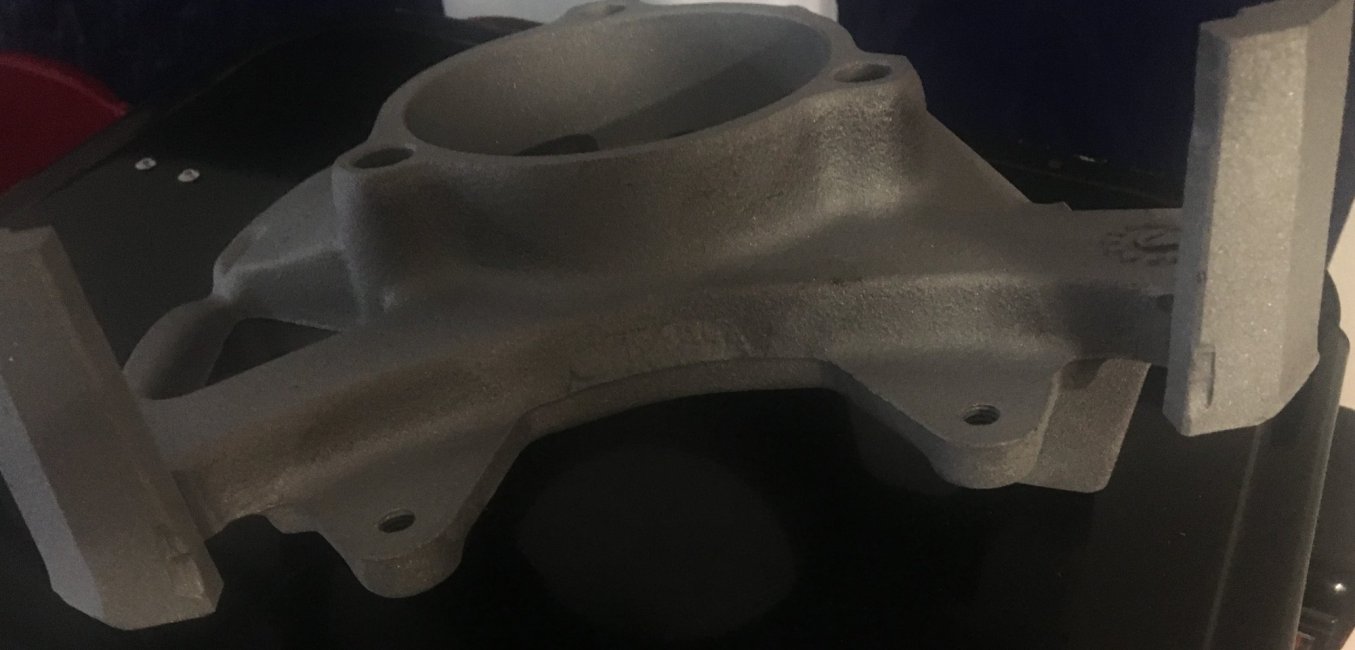

I'm looking to see if someone would be willing to weld a small bead on a cast iron steering knuckle to fill a divot. I would grind it down smooth after. I just need someone who is willing to heat up the part, put a bead on. I'll help if there is such a thing. You can see the divot in the pic, lower right and left portion where the brake pads ride. I'm coming to Evansville this weekend so I could bring them with me if someone down there would do it on Saturday or Sunday morning. Thanks.