Here's another fun project. A James Madison 80% polymer lower receiver and a 16 inch carbine upper. All built from kits.

The lower was designed to be able to be done with a mill or a drill press. I don't think I'd try this with a drill press. But it could be done. Just not by me! Especially since I have a mill!

The receiver is a James Madison 80% polymer. The upper kit came from a seller on weaponguild.com. It's a generic kit. The lower parts kit came from Remauto1187's parts stash. Thanks Mike! The buffer tube, butt stock and tooling came from JSE surplus. I bought the correct block to hold the receiver and the upper correctly. I bought a multi wrench to bolt the barrel and the buffer tube correctly. I doubt this will be my last build so the tools will be handy!

I used my 3:1 lathe/mill. It's an older Harbor Freight that I got a deal on a few ears ago. Basically was new when I got it. I have since added DRO's and a Aloris style tool post for the lathe side of things. It's a awesome machine for general gunsmithing stuff.

This is the lower with the milling jig. Picture courtesy of James Madison website.

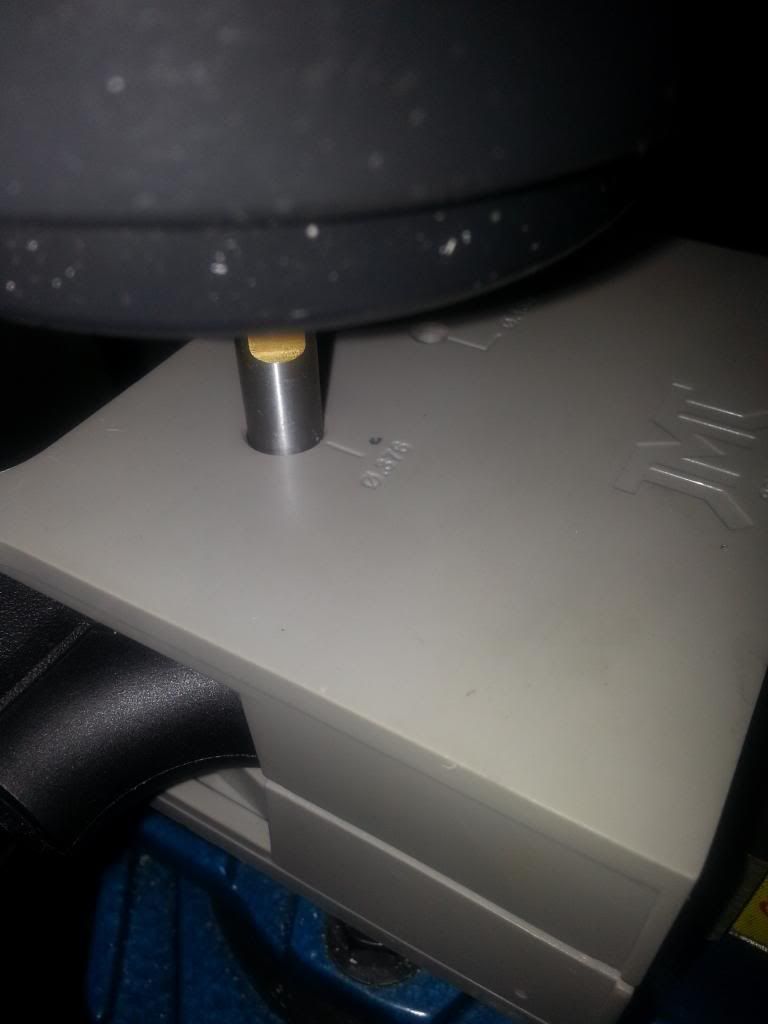

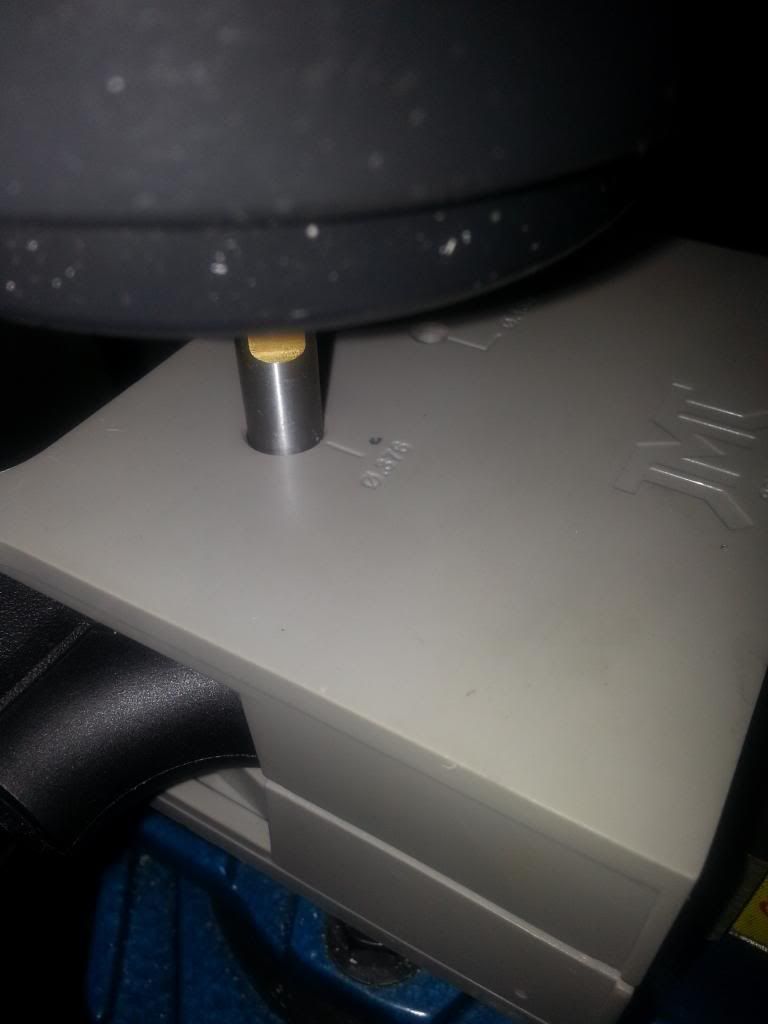

This receiver is from there first batch of production. There turned out to be errors with the jig. I lucky when to there website and got updated instructions before I got started. Here is the jig/receiver in the mill vice.

I am centering the bit in the hole. This it the selector switch hole. the original directions said to drill the holes 3/4 way threw the receiver and flip it over and drill the other side. The jig was made wrong. the New directions say the fix is to just drill all the way threw the receiver. The holes lined up perfectly. The new jigs/receivers have bend updated

I did not get any pics of milling the trigger pocket (hard to film and cut lol) but it is straight forward. Just mill inside the lines. The directions give the depth of the different areas. It came out great. the trigger and the selector fits and functions fine.

I forgot to mention my assistant. My son "J" He help a lot with the upper barrel assembly. He learn a new tool. A torque wrench. He did well. He lined the gas tube hole up perfectly. He is really interested in gunsmithing and mechanics in general. I am proud of that. he's getting to be just like the old man. He is even learning how to run the mill and the lathe.

He did not like the smell of the Moly Lube we used on the barrel and the barrel nut. I told him he'll get used to it if he's a real man lol.

Here it is! It shoots perfect. And J is a really happy! I still need to tinker with he flash hider. I need some index washers to line it up correctly.

I did have one PIA situation with the gas block. I could not get the roll pin in. I would get it started and it would bend. I shake to much due to some health issues :-( But I don't let it get me down! I ended up using the drill press as a arbor press. I flipped a drill bit upside down and us it as the punch. I was able to push my bent pin out and press the new pin in. It all worked out well. Problem solved.

The next AR 80% build will be a aluminum one. I learned a lot doing this one. It was fun to build another gun with my son! Hopefully we have many more builds in our future. Another Sten gun is ready to be welded but that a subject for another post...

The lower was designed to be able to be done with a mill or a drill press. I don't think I'd try this with a drill press. But it could be done. Just not by me! Especially since I have a mill!

The receiver is a James Madison 80% polymer. The upper kit came from a seller on weaponguild.com. It's a generic kit. The lower parts kit came from Remauto1187's parts stash. Thanks Mike! The buffer tube, butt stock and tooling came from JSE surplus. I bought the correct block to hold the receiver and the upper correctly. I bought a multi wrench to bolt the barrel and the buffer tube correctly. I doubt this will be my last build so the tools will be handy!

I used my 3:1 lathe/mill. It's an older Harbor Freight that I got a deal on a few ears ago. Basically was new when I got it. I have since added DRO's and a Aloris style tool post for the lathe side of things. It's a awesome machine for general gunsmithing stuff.

This is the lower with the milling jig. Picture courtesy of James Madison website.

This receiver is from there first batch of production. There turned out to be errors with the jig. I lucky when to there website and got updated instructions before I got started. Here is the jig/receiver in the mill vice.

I am centering the bit in the hole. This it the selector switch hole. the original directions said to drill the holes 3/4 way threw the receiver and flip it over and drill the other side. The jig was made wrong. the New directions say the fix is to just drill all the way threw the receiver. The holes lined up perfectly. The new jigs/receivers have bend updated

I did not get any pics of milling the trigger pocket (hard to film and cut lol) but it is straight forward. Just mill inside the lines. The directions give the depth of the different areas. It came out great. the trigger and the selector fits and functions fine.

I forgot to mention my assistant. My son "J" He help a lot with the upper barrel assembly. He learn a new tool. A torque wrench. He did well. He lined the gas tube hole up perfectly. He is really interested in gunsmithing and mechanics in general. I am proud of that. he's getting to be just like the old man. He is even learning how to run the mill and the lathe.

He did not like the smell of the Moly Lube we used on the barrel and the barrel nut. I told him he'll get used to it if he's a real man lol.

Here it is! It shoots perfect. And J is a really happy! I still need to tinker with he flash hider. I need some index washers to line it up correctly.

I did have one PIA situation with the gas block. I could not get the roll pin in. I would get it started and it would bend. I shake to much due to some health issues :-( But I don't let it get me down! I ended up using the drill press as a arbor press. I flipped a drill bit upside down and us it as the punch. I was able to push my bent pin out and press the new pin in. It all worked out well. Problem solved.

The next AR 80% build will be a aluminum one. I learned a lot doing this one. It was fun to build another gun with my son! Hopefully we have many more builds in our future. Another Sten gun is ready to be welded but that a subject for another post...

Last edited: