IndyGunworks

Grandmaster

I am in the process of trying to learn all the machining skills required for gunsmithing. This is a long term goal and not something I expect to achieve overnight. This is a dovetail I cut into a piece of conduit because I didnt want to take a chance of 1. destroying a 50 dollar dovetail cutter before I even knew what i was doing, and 2. the material is softer and easily replaced if I had goofed something up.

I had a front sight sitting around that measured around .330 w/ a 60 degree dovetail, and around .075 high, which happens to be what dovetail cutter i had laying around, so thats what i decided to use. I dont know what it came off of but that doesnt really matter.

I started off by tramming in my vise to make sure the dovetail was going to be square. I used a .0005 test indicator and got the vise trammed in to w/in a half though of square.

Then i squared the end and sides of the conduit to make it look feel and act like a 1911 slide in the vice and during fitting/machining.

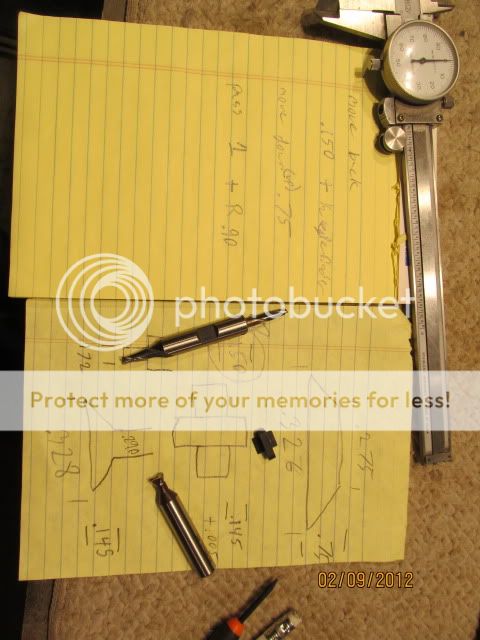

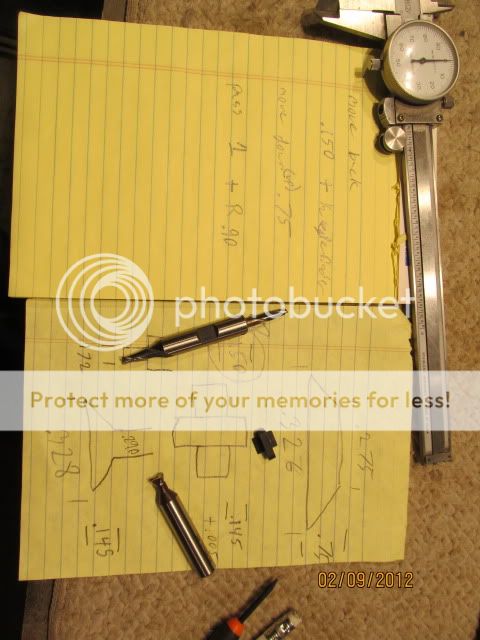

then i took notes down, and wrote a plan of action on how everything was going to work. (this kind of changed mid plan because i had not calculated center correctly. but it still all worked out.

I was lucky that all three tool, edge finder, end mill, and dovetail cutter all used the same collet (3/8) so i wouldnt have to do a ton of swapping of collets.

Then i leveled the piece

After i found the edge, and moved back as far as i needed to, i found the top of the work piece using a piece of paper that measure .003. this is the only measurement that i messed up on a little bit. I think when i found the top of the paper i went an extra thou or two down because when i was fitting the sight i had to remove a few thousands to keep it from rubbing on the top of the "slide". I need to find a better way to find the top of my workpiece more precisly and i think this issue will go away.

After lopping out most of the material I ran the dovetail cutter through. I dont have any pictures because this is where i thought i was really going to mess up after hearing lots of horror stories.

Per my math the sight was going to be about .001 undersized w/ one pass of the dovetail cutter, but the cutter was VERY hard to measure. so i made a pass and tried the sight. It wouldnt fit! oh well, removed another .002, and tried again, then another .001, then another .001. after that last pass the sight went about 1/3rd of the way into the dovetail so i knew i had hit the mark perfectly.

A little bit of fitting and here she is.

I had a front sight sitting around that measured around .330 w/ a 60 degree dovetail, and around .075 high, which happens to be what dovetail cutter i had laying around, so thats what i decided to use. I dont know what it came off of but that doesnt really matter.

I started off by tramming in my vise to make sure the dovetail was going to be square. I used a .0005 test indicator and got the vise trammed in to w/in a half though of square.

Then i squared the end and sides of the conduit to make it look feel and act like a 1911 slide in the vice and during fitting/machining.

then i took notes down, and wrote a plan of action on how everything was going to work. (this kind of changed mid plan because i had not calculated center correctly. but it still all worked out.

I was lucky that all three tool, edge finder, end mill, and dovetail cutter all used the same collet (3/8) so i wouldnt have to do a ton of swapping of collets.

Then i leveled the piece

After i found the edge, and moved back as far as i needed to, i found the top of the work piece using a piece of paper that measure .003. this is the only measurement that i messed up on a little bit. I think when i found the top of the paper i went an extra thou or two down because when i was fitting the sight i had to remove a few thousands to keep it from rubbing on the top of the "slide". I need to find a better way to find the top of my workpiece more precisly and i think this issue will go away.

After lopping out most of the material I ran the dovetail cutter through. I dont have any pictures because this is where i thought i was really going to mess up after hearing lots of horror stories.

Per my math the sight was going to be about .001 undersized w/ one pass of the dovetail cutter, but the cutter was VERY hard to measure. so i made a pass and tried the sight. It wouldnt fit! oh well, removed another .002, and tried again, then another .001, then another .001. after that last pass the sight went about 1/3rd of the way into the dovetail so i knew i had hit the mark perfectly.

A little bit of fitting and here she is.

Looking forward to part II.

Looking forward to part II.