I took the FCD apart this evening to clean and prep for shortening. One thing I notice is, on the picture of Djones' FCD you can see some of the "45-70" stamping left on the end. They must have changed the design somewhat because when I take .305 off the whole stamp will be gone. My collet is held in the die by the tension of the split fingers and I think maybe the old ones were held by a split ring affair. Anyway, off in the morning to sight the new gun in and generate some brass for shortening.

-

Be sure to read this post! Beware of scammers. https://www.indianagunowners.com/threads/classifieds-new-online-payment-guidelines-rules-paypal-venmo-zelle-etc.511734/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Question for you folks reloading the 45-70 1.8 inch cartridges for Indiana deer

- Thread starter Flinttim

- Start date

The #1 community for Gun Owners in Indiana

Member Benefits:

Fewer Ads! Discuss all aspects of firearm ownership Discuss anti-gun legislation Buy, sell, and trade in the classified section Chat with Local gun shops, ranges, trainers & other businesses Discover free outdoor shooting areas View up to date on firearm-related events Share photos & video with other members ...and so much more!

Member Benefits:

17 squirrel

Shooter

- May 15, 2013

- 4,427

- 63

Ahhh. Can't you run the adjustment screw down ????

17 squirrel

Shooter

- May 15, 2013

- 4,427

- 63

Ahhhhh, now I understand. in most cases I don't do Lee. but for some uses I do like Lees collet crimp die. I would believe that you will have to machine the bottom of that die also.

I don't use a expander either, I ream the inside of the neck with a 30 degree ? chamfer tool and I seat with a Meacham Inline Bullet seater.

http://www.meachamtool.com/

is the expander die you have a powder through expander die ????

I don't use a expander either, I ream the inside of the neck with a 30 degree ? chamfer tool and I seat with a Meacham Inline Bullet seater.

http://www.meachamtool.com/

is the expander die you have a powder through expander die ????

Yes, it's a thru die. I thought maybe a 5/8-18 bolt in there would keep the expander from going up too far. But I dug out some 45-70 cases that I looked at my calipers wrong and cut them off at 1.7 ", reamed them and the bullet goes in by finger pressure. I hope at 1.8 they load a bit harder than that. May have to bump 'em in the crimp die before loading.

Hey guys. The last batch I loaded I used the Lee universal case expander with a NOE expander plug.

.460 x .456 Exp. Plug, NOE Bullet Moulds

.460 x .456 Exp. Plug, NOE Bullet Moulds

17 squirrel

Shooter

- May 15, 2013

- 4,427

- 63

I would think that just the universal expander would do what he needs.

What county do you live in Flint ?

I have a set of rcbs 45-70 dies that I just use for lever action rifles. They really size the necks down. If I get a chance on Monday I'll cut off a case and see how well they resize and flair a short case. I also have Redding dies but I will not be around them for a week or so. Heck, now I'm curious.

With using a inline seater I never have had these problems. And I use longer / heavier bullet and they make up for the difference in cutting off the cases.

Good thread Gentlemen.

What county do you live in Flint ?

I have a set of rcbs 45-70 dies that I just use for lever action rifles. They really size the necks down. If I get a chance on Monday I'll cut off a case and see how well they resize and flair a short case. I also have Redding dies but I will not be around them for a week or so. Heck, now I'm curious.

With using a inline seater I never have had these problems. And I use longer / heavier bullet and they make up for the difference in cutting off the cases.

Good thread Gentlemen.

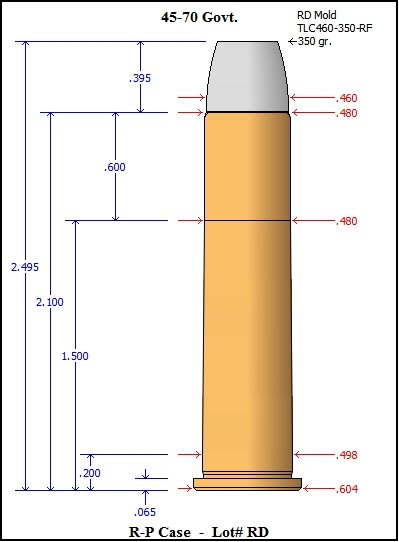

I'm down in Seymour 17. I'm not adverse to turning the neck expander die down I assume you would cut it down the same .305 as the crimp die. But due to the fact that a 45-70 case has some small taper to it , not sure how that would affect things. (if anyone knows the answer to this please advise). Here's the low down. A 45-70 case at full length has an inside the neck diameter of "X" amount. When we prune it back to 1.79-1.8, that ID gets larger. There should be minimal neck expanding needed.. I took one full length case, not resized, cut it off too short , about 1.740, junk at that point. Anyway, after chamfering the outside and inside I could push the bullet in by finger. There could not be that much neck expanding needed.

17 squirrel

Shooter

- May 15, 2013

- 4,427

- 63

When you size the trimmed brass in the sizing die that's been shortened the neck of the trimmed brass should end up with the same X you had with full size brass and a untrimmed die.

With cutting off the bottom of the die shouldn't change what happens at the top of the die. Are you sure you trimmed off enough ?

With cutting off the bottom of the die shouldn't change what happens at the top of the die. Are you sure you trimmed off enough ?

I've only turned down the crimp die. You turn down the crimp die the difference between a 1.8" case and a full length case (.305), so it would make sense to shorten the neck expander die the same amount so the ram is traveling the same distance in both. But you are right about one thing. My 1.8 case comes up .305 short from engaging the neck expander in the expander die so taking the .305 off it won't change the relationship of the case to the expander. I looked into the actual measurements of a 45-70 case someone had on the Internet. The case is straight back for some distance before it gets larger in diameter. The 1.8 case is till inside that area ie: the mouth opening is the same whether it's long or short.

17 squirrel

Shooter

- May 15, 2013

- 4,427

- 63

Yes, and unless you trim the sizer die you will not size down the neck to get good tension required to hold the bullet tight.

You might not have to trim off as much, but you will have to trim off some.

Another option is to slug the bore and see the diameter you actually have. And with that you may can shoot a larger diameter bullet. Like a as cast bullet that doesn't need to get sized. I shoot in two rifles with a as cast ( .459) bullet, I lube it in a .460 sizer die, and the bullet doesn't touch the die, it just gets lubed.

And if you can use a larger bullet, you will not have to size the brass down so much.

You might not have to trim off as much, but you will have to trim off some.

Another option is to slug the bore and see the diameter you actually have. And with that you may can shoot a larger diameter bullet. Like a as cast bullet that doesn't need to get sized. I shoot in two rifles with a as cast ( .459) bullet, I lube it in a .460 sizer die, and the bullet doesn't touch the die, it just gets lubed.

And if you can use a larger bullet, you will not have to size the brass down so much.

Last edited:

Well, I turned the neck expanding die down after church today. Cuts easy on the lathe. Now the whole thing works as it would work on a full length case and by adjusting the die in the press you can still use it on full length cases. I had a case already cut down too much (1.750) and give it a go in the expander and set the bullet seating die up for the short cases too. No cutting down on it, just a bit of initial adjusting, maybe a it more than a full length case would take but not bad at all. Soon as my large case cutter gets here and my bullet sizing die , I'm ready. One thing on my agenda is to look into reworking a standard 45-70 case length gauge to fit the short cases. The 460S&W will work but does not have as much supporting surface for the 45-70 cases. I have a regular 45-70 gauge coming so we will see.

The 45-70 trim gauge and large cutter came today. I turned the trim gauge down to result in a case 1.793". Chuck the cutter and gauge in my lathe, put a case in a collet and lock nut and in less than 20seconds you have an Indiana legal deer case.

I just have a small 19" lathe David. Mostly I use it to make screws , ramrod tips, cleaning jags etc for my flintlocks I build. But it works perfectly for this too. One thing I recommend is the large Lee cutter for the 45-70. Works way better than the small one. Also the 460 Smith trim gauge is not as big in diameter as the 45-70 and it tends to "wiggle" the cases a bit , not cutting as clean a cut. On the 45-70 trim gauge I just set my lathe bit at the same angle as the factory angle . cut it back .305 and left the small part that goes thru the primer pocket long. I did not want to take the chance of cutting it down with the lathe. I just slid the gauge into a case already cut down and then nipped the guide off with side cutters and then fine tuned the length with a file while it turned in the lathe till I got the length I wanted. A better machinist than I could do it all with the lathe I imagine. Merry Christmas.

Members online

- El Conquistador

- jspy5

- SEIndSAM

- Reece'sPieces

- AndreusMaximus

- Geoman1

- slims2002

- jbm1521

- Tradesylver

- m4_dave

- SOUP

- JoeBear44

- 812 rimfire

- WhitleyStu

- BrettonJudy7

- tim7431

- Dutchmaster

- shootersix

- Tac.ticalJoe

- Snapdragon

- gcfireman

- papa6x

- drgnrobo

- MCgrease08

- Aggar

- HD1

- 63PGP

- Steve

- Colt556

- hunt4fun

- Floivanus

- led4thehed2

- 257robertsimp

- indydrummer

- syntax357

- Steel and wood

- HoosierHunter07

- ranger04

- LeftyGunner

- Ozark1897

Total: 1,855 (members: 46, guests: 1,809)