INGO always provides well when it comes to spending other's money, right?

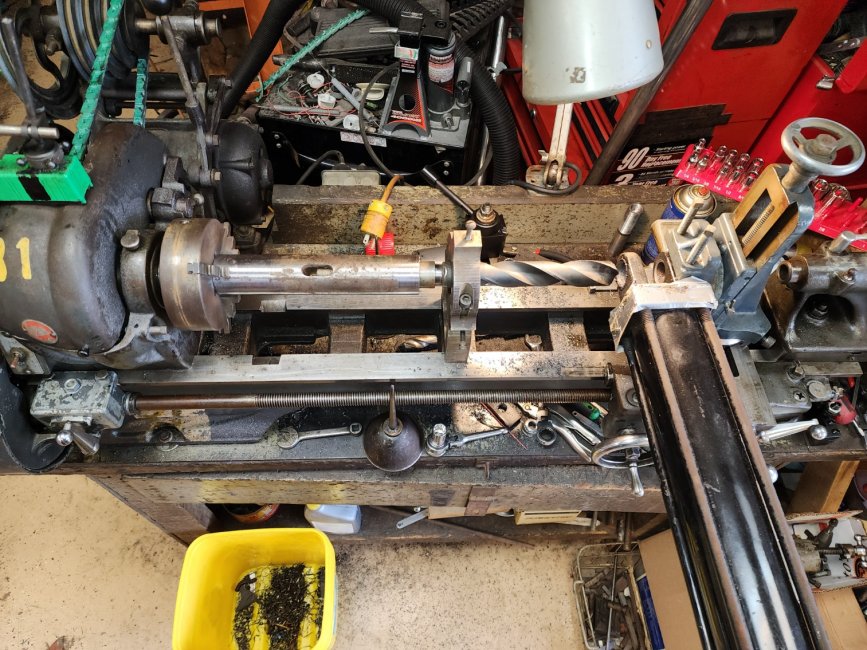

There are some machining type folks in here that I'm sure have a good answer for this. A few months ago I bought a well used lathe with almost as much weight in drill bits. Some of them are in better shape, some need a little love. I have a drill doc 750 that works up to 3/4", are there any good products out there for sharpening twist bits up to 1.5" (under $500)? I have a steady hand but like the consistency of a jig. Always second guessing if I have the right angles.

Google, of course, produces 50 bot-generated listicles for the same 5 products: 3 drill doc models and 2 Chinesium grinder jigs. With some tinkering with the phrasing, I did come across some that might work... starting at $1800. or this DIY jig: https://www.christofix.com/everyone-can-sharpen-drill-bits-with-this-jig/ (best viewed with adblocker, seems like a solid article but 2x the ads as article space)

There are some machining type folks in here that I'm sure have a good answer for this. A few months ago I bought a well used lathe with almost as much weight in drill bits. Some of them are in better shape, some need a little love. I have a drill doc 750 that works up to 3/4", are there any good products out there for sharpening twist bits up to 1.5" (under $500)? I have a steady hand but like the consistency of a jig. Always second guessing if I have the right angles.

Google, of course, produces 50 bot-generated listicles for the same 5 products: 3 drill doc models and 2 Chinesium grinder jigs. With some tinkering with the phrasing, I did come across some that might work... starting at $1800. or this DIY jig: https://www.christofix.com/everyone-can-sharpen-drill-bits-with-this-jig/ (best viewed with adblocker, seems like a solid article but 2x the ads as article space)