Did that story go that it became a full restoration?I have many regrets in life. How the Ventura went down is one of them. I either should’ve moved on from it after the crash or fixed the quarter and kept the drivetrain as it was when I bought it.

-

Be sure to read this post! Beware of scammers. https://www.indianagunowners.com/threads/classifieds-new-online-payment-guidelines-rules-paypal-venmo-zelle-etc.511734/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Official Hot Rod Thread - Part 4: Burnouts for Distance

- Thread starter churchmouse

- Start date

The #1 community for Gun Owners in Indiana

Member Benefits:

Fewer Ads! Discuss all aspects of firearm ownership Discuss anti-gun legislation Buy, sell, and trade in the classified section Chat with Local gun shops, ranges, trainers & other businesses Discover free outdoor shooting areas View up to date on firearm-related events Share photos & video with other members ...and so much more!

Member Benefits:

ChristianPatriot

Grandmaster

I for sure lost big on the Ventura.

ChristianPatriot

Grandmaster

Did that story go that it became a full restoration?

No idea what happened to it after it left my driveway

No idea what happened to it after it left my driveway

Oh... Sold it wrecked?

ChristianPatriot

Grandmaster

Oh... Sold it wrecked?

Yeah I put the new drivetrain in it after the incident

femurphy77

Grandmaster

I've most of the fixins for a 393 stroker out in the shop; we set up a gofundme for the missing pieces and he can build it for ME!!Well, next time you're going to have to build him a SBF as a joke.

Of course then we'd have to do the same thing for the 410 Merc that's going in the Galaxie and I just don't seem to have any time for that 24 hp honda v twin into the golf cart project. . . . . . .

ChristianPatriot

Grandmaster

I’d definitely be some kind of machinist/engine builder if I could. I love that stuff.

The right converter and tune up would have made that one a heck of a lot more fun.I have many regrets in life. How the Ventura went down is one of them. I either should’ve moved on from it after the crash or fixed the quarter and kept the drivetrain as it was when I bought it.

Thing is it was a brute. It had a personality that is more fitting to me. You prefer the FI engines and the drivability of a Turbo.

Me.........Well you already know. Mean pissed off and ready to rumble is how I like my hot rods. I like that switch.

I forgot all about that 410.I've most of the fixins for a 393 stroker out in the shop; we set up a gofundme for the missing pieces and he can build it for ME!!

Of course then we'd have to do the same thing for the 410 Merc that's going in the Galaxie and I just don't seem to have any time for that 24 hp honda v twin into the golf cart project. . . . . . .

femurphy77

Grandmaster

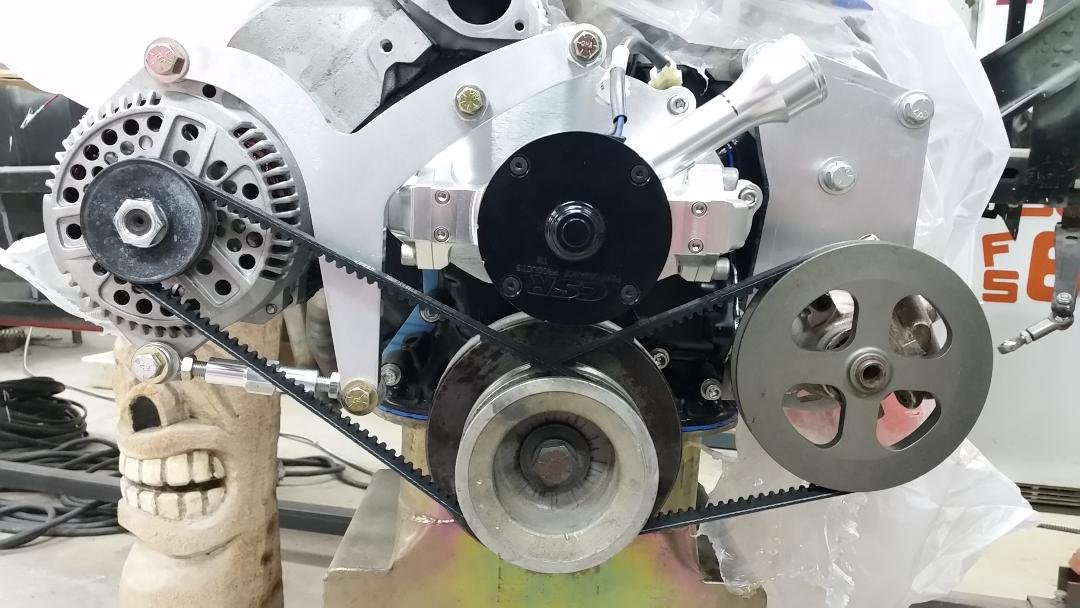

Ok is there some reason I can't do this?

Or more clearly this:

I'm having problems with belts, pulleys and electric water pumps. I've been working with a vendor of accessory mount and drive kits trying to bring my frankenstein drive system home and even if I start over and buy a complete system from them it still won't work with my engine due to the KRC race power steering pump I'm using. It'll work with a factory power steering pump but not an aftermarket race pump. WHY do I insist on using a KRC race pump you ask? Because I've fried countless factory pumps thru the years on my autocross cars at least until I ponied up for a purpose built pump.

So in getting all the belt driven equipment, alternator and ps pump, lined up on the crank pulley it causes those accessories to interfere with the outlet of the water pump. I was looking at it this morning and thought about flipping the pump upside down and having the outlet come out of the top of the pump instead of the bottom. The only downside I see is a long connection to the radiator, hence more hose to fail.

The solution to limit hose failure would just be to use stainless tubing bent to fit and use a short piece of hose on each end to connect to the pump and to the radiator.

I know it looks weird but at this point I'm open to almost anything that allows me to keep the electric water pump and KRC race PS pump. One more thing that plays into this is that I can't raise the pump or alternator any higher as the belt will hit the water pump.

Or more clearly this:

I'm having problems with belts, pulleys and electric water pumps. I've been working with a vendor of accessory mount and drive kits trying to bring my frankenstein drive system home and even if I start over and buy a complete system from them it still won't work with my engine due to the KRC race power steering pump I'm using. It'll work with a factory power steering pump but not an aftermarket race pump. WHY do I insist on using a KRC race pump you ask? Because I've fried countless factory pumps thru the years on my autocross cars at least until I ponied up for a purpose built pump.

So in getting all the belt driven equipment, alternator and ps pump, lined up on the crank pulley it causes those accessories to interfere with the outlet of the water pump. I was looking at it this morning and thought about flipping the pump upside down and having the outlet come out of the top of the pump instead of the bottom. The only downside I see is a long connection to the radiator, hence more hose to fail.

The solution to limit hose failure would just be to use stainless tubing bent to fit and use a short piece of hose on each end to connect to the pump and to the radiator.

I know it looks weird but at this point I'm open to almost anything that allows me to keep the electric water pump and KRC race PS pump. One more thing that plays into this is that I can't raise the pump or alternator any higher as the belt will hit the water pump.

You can make anything fit anywhere if you either....Ok is there some reason I can't do this?

View attachment 134882

Or more clearly this:

View attachment 134883

I'm having problems with belts, pulleys and electric water pumps. I've been working with a vendor of accessory mount and drive kits trying to bring my frankenstein drive system home and even if I start over and buy a complete system from them it still won't work with my engine due to the KRC race power steering pump I'm using. It'll work with a factory power steering pump but not an aftermarket race pump. WHY do I insist on using a KRC race pump you ask? Because I've fried countless factory pumps thru the years on my autocross cars at least until I ponied up for a purpose built pump.

So in getting all the belt driven equipment, alternator and ps pump, lined up on the crank pulley it causes those accessories to interfere with the outlet of the water pump. I was looking at it this morning and thought about flipping the pump upside down and having the outlet come out of the top of the pump instead of the bottom. The only downside I see is a long connection to the radiator, hence more hose to fail.

The solution to limit hose failure would just be to use stainless tubing bent to fit and use a short piece of hose on each end to connect to the pump and to the radiator.

I know it looks weird but at this point I'm open to almost anything that allows me to keep the electric water pump and KRC race PS pump. One more thing that plays into this is that I can't raise the pump or alternator any higher as the belt will hit the water pump.

A) drink enough beer and stare at it long enough or

B) Just dig in and make the spacers and such. And drink beer. It makes the engineering process flow along.

Putting the impossible next to the improbable and expecting perfection.

femurphy77

Grandmaster

DAMMIT! That's where I screwed up. I FORGOT THE BEER!!You can make anything fit anywhere if you either....

A) drink enough beer and stare at it long enough or

B) Just dig in and make the spacers and such. And drink beer. It makes the engineering process flow along.

Putting the impossible next to the improbable and expecting perfection.

Anything is possible.DAMMIT! That's where I screwed up. I FORGOT THE BEER!!

If you need special bushings/spacers shoot me the specs and I will spin them up for you. I am not above making parts for a Ford.....

Jaybird1980

Grandmaster

That should be the inlet of the water pump not outlet right? Unless it's some sort of reverse flow, I don't think it is. The inlet needs to be flooded to prevent starving the pump and causing cavitation. That's why it is lower than the top of the fluid level. The fluid pressure will fill the pump instead of the pump trying to suck fluid to it.Ok is there some reason I can't do this?

View attachment 134882

Or more clearly this:

View attachment 134883

I'm having problems with belts, pulleys and electric water pumps. I've been working with a vendor of accessory mount and drive kits trying to bring my frankenstein drive system home and even if I start over and buy a complete system from them it still won't work with my engine due to the KRC race power steering pump I'm using. It'll work with a factory power steering pump but not an aftermarket race pump. WHY do I insist on using a KRC race pump you ask? Because I've fried countless factory pumps thru the years on my autocross cars at least until I ponied up for a purpose built pump.

So in getting all the belt driven equipment, alternator and ps pump, lined up on the crank pulley it causes those accessories to interfere with the outlet of the water pump. I was looking at it this morning and thought about flipping the pump upside down and having the outlet come out of the top of the pump instead of the bottom. The only downside I see is a long connection to the radiator, hence more hose to fail.

The solution to limit hose failure would just be to use stainless tubing bent to fit and use a short piece of hose on each end to connect to the pump and to the radiator.

I know it looks weird but at this point I'm open to almost anything that allows me to keep the electric water pump and KRC race PS pump. One more thing that plays into this is that I can't raise the pump or alternator any higher as the belt will hit the water pump.

That should be the inlet of the water pump not outlet right? Unless it's some sort of reverse flow, I don't think it is. The inlet needs to be flooded to prevent starving the pump and causing cavitation. That's why it is lower than the top of the fluid level. The fluid pressure will fill the pump instead of the pump trying to suck fluid to it.

I believe this is correct.

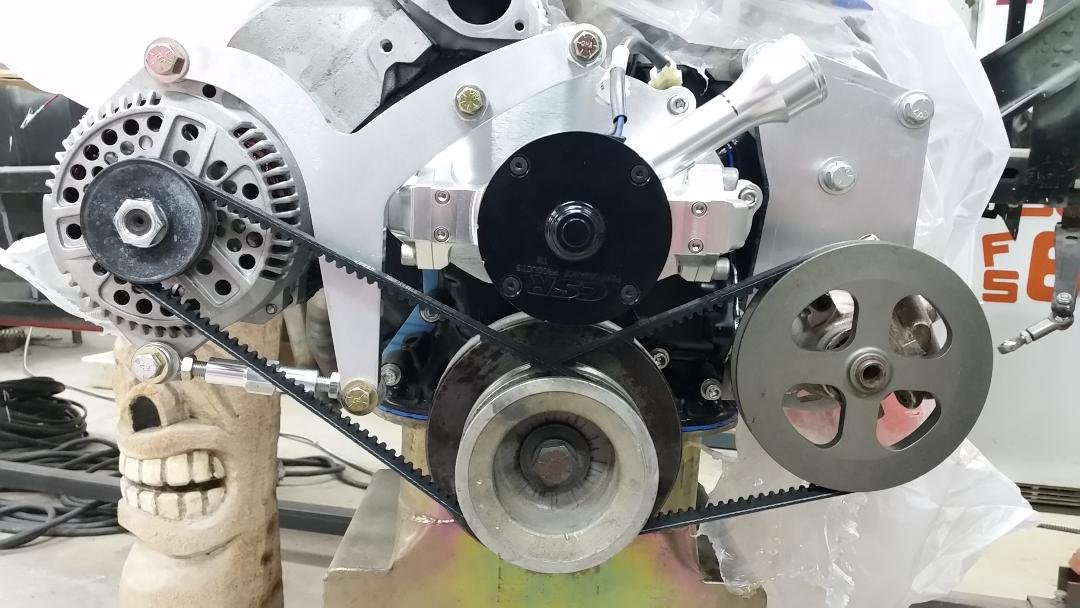

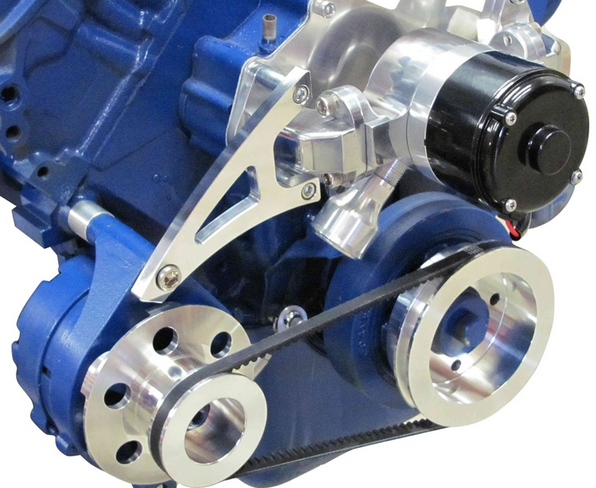

Also... You have a country mile to drop the alternator if you want to and it seems like getting the CG down would be nice anyhow. Drop the alternator and go with a hose neck that isn't a yard long and it should package a little easier, as shown below. If CSR doesn't offer a neck for sale, it shouldn't be too tough for any machine shop to cut yours down and re-thread it.

Jaybird1980

Grandmaster

I'm not sure if the alternator bracket is in the way or what. If there was a pic of it fit up the other way to show where the interference is would help. The alt. bracket you have shown differs from FemurphyI believe this is correct.

Also... You have a country mile to drop the alternator if you want to and it seems like getting the CG down would be nice anyhow. Drop the alternator and go with a hose neck that isn't a yard long and it should package a little easier, as shown below. If CSR doesn't offer a neck for sale, it shouldn't be too tough for any machine shop to cut yours down and re-thread it.

View attachment 134894

I'm not sure if the alternator bracket is in the way or what. If there was a pic of it fit up the other way to show where the interference is would help. The alt. bracket you have shown differs from Femurphy

Correct. What I showed above is a low mount alternator bracket setup. What he has now is what I would think of as a mid-mount, maybe approaching a high-mount.

I believe if he flips the pump over the hose connection will interfere with the belt on his current setup. By dropping the alternator with a low mount kit, and shortening the barb, it should clear.

femurphy77

Grandmaster

That should be the inlet of the water pump not outlet right? Unless it's some sort of reverse flow, I don't think it is. The inlet needs to be flooded to prevent starving the pump and causing cavitation. That's why it is lower than the top of the fluid level. The fluid pressure will fill the pump instead of the pump trying to suck fluid to it.

Good point I hadn't thought of that. Man you gotta love the INGO hotrod mensa group!

femurphy77

Grandmaster

I believe this is correct.

Also... You have a country mile to drop the alternator if you want to and it seems like getting the CG down would be nice anyhow. Drop the alternator and go with a hose neck that isn't a yard long and it should package a little easier, as shown below. If CSR doesn't offer a neck for sale, it shouldn't be too tough for any machine shop to cut yours down and re-thread it.

View attachment 134894

I have looked into lowering the alternator and the opportunity to lower the CG especially of that heavy ass 4g alternator is enticing but my block doesn't have the threaded boss that this one is mounted to. Of course it's no problem fab a mount that bolts to the head to get that lower mounting point. I'd prefer to have that engine, if I'm right that's a Boss 302!

Correct. What I showed above is a low mount alternator bracket setup. What he has now is what I would think of as a mid-mount, maybe approaching a high-mount.

I believe if he flips the pump over the hose connection will interfere with the belt on his current setup. By dropping the alternator with a low mount kit, and shortening the barb, it should clear.

I have found a shorter barb to replace the long one I have that I'm going to try to use with my existing set up but I believe that it will put the radiator hose up against the backside of my current alternator bracket right where the tensioner bolt goes thru. I've also found a threaded 45 degree elbow that I've ordered that would move the outlet enough to provide clearance but it may be to weak for my use.

Jaybird1980

Grandmaster

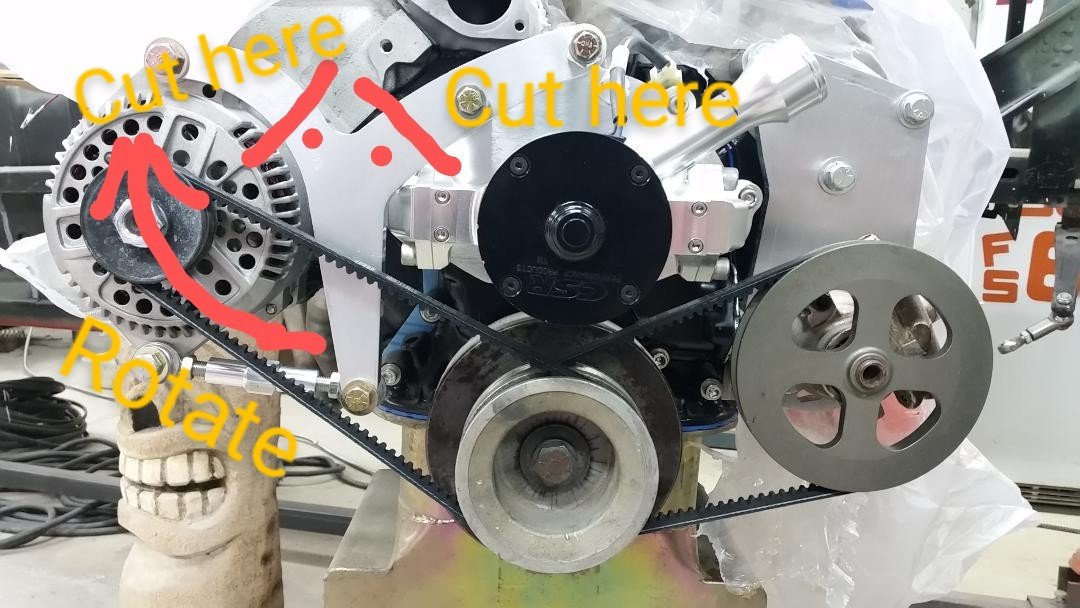

This is what I think I would do. And just looking at it you may be able to mod the bracket you already have, and use the lower head bolt.I have looked into lowering the alternator and the opportunity to lower the CG especially of that heavy ass 4g alternator is enticing but my block doesn't have the threaded boss that this one is mounted to. Of course it's no problem fab a mount that bolts to the head to get that lower mounting point. I'd prefer to have that engine, if I'm right that's a Boss 302!

I even will provide a detail blueprint to show you what I mean. Just follow these carefully laid out plans.

You're welcome.

Latest posts

-

NWI INGO General Thread #27 - Fresh Pink Air On US-30 smells like...

- Latest: Ballstater98

-

-

-

Staff online

-

KellyinAvonBlue-ID Mafia Consigliere

-

mom45Momerator

Members online

- diverjes06

- INP8riot

- Michigan Slim

- lrdudley

- KellyinAvon

- CheeseRat

- russc2542

- Bosshoss

- Batchief909

- Brian 45

- ypayton134

- BluePig

- freekforge

- johnb62

- Ziggidy

- Wolfhound

- OutdoorDad

- Splagt

- Reale1741

- jtbriles

- Jeronimo

- CB1911

- Timjoebillybob

- Jimbo74

- nhgluff

- EvilElmo

- williamsburg

- Creedmoor

- mom45

- Damdamdon

- Work

- Jdr308

- Talkinghalls

- Highstandard

- Noble Sniper

- Super Bee

- Luke9455

- cbickel

- REM299

- ChrisK

- rbhargan

- ars

- PSOD

- x34822

- MDpolo

- bking1340

- Bollorollo

- dmeadlo

- Ark

- Trapper Jim

Total: 1,855 (members: 303, guests: 1,552)