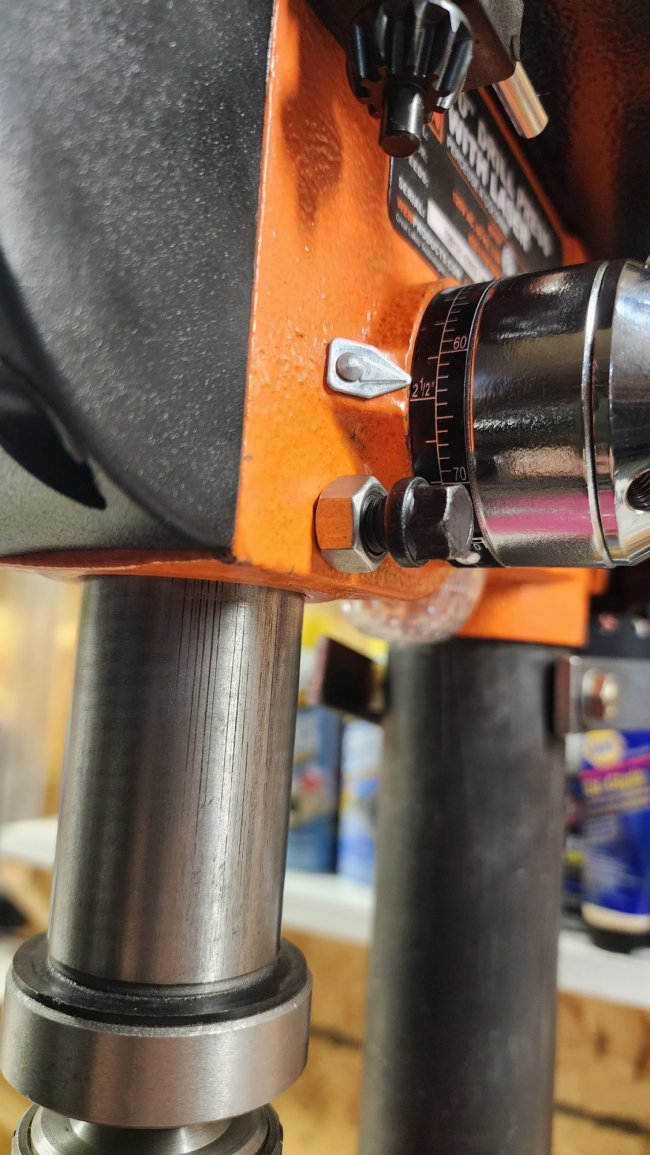

Think I'm going to do a few more optic cuts on a couple of guns eventually, but do some more practicing beforehand. Upgrading my pseudo mill to see just how much use I get doing milling operations until I decide I need a real mill. Ordered a 2-axis DRO kit, a digital depth gauge made for a drill press and some actual machinist jacks. Last night I reinforced the column by bracing it to the wall. Much better, but now the stuff on the wall vibrates depending on press rpm. Oh well.