What is a farmer tolerance?? Tenthousanths? As in .010 or "tenths" as on .0001?? Most of the time ½ thou (.0005) is plenty close enough for me.......you guys forget I'm a die maker.Oh hi there you know about “farmer tolerance” too?

These guys that talk in tenthousanths can really be bothersome.

-

Be sure to read this post! Beware of scammers. https://www.indianagunowners.com/threads/classifieds-new-online-payment-guidelines-rules-paypal-venmo-zelle-etc.511734/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Milling and mounting for a red dot

- Thread starter ditcherman

- Start date

The #1 community for Gun Owners in Indiana

Member Benefits:

Fewer Ads! Discuss all aspects of firearm ownership Discuss anti-gun legislation Buy, sell, and trade in the classified section Chat with Local gun shops, ranges, trainers & other businesses Discover free outdoor shooting areas View up to date on firearm-related events Share photos & video with other members ...and so much more!

Member Benefits:

I'm sure there are plenty of people laughing for different reasons. I can't say I blame them either. I laugh at myself quite a bit.I have to laugh looking at what you are all getting done with the equipment you are using. We have all of the fancy stuff at work and still have guys whining to no end about how that can't do this, that, or the other.

It was in reference to a comment I made earlier - my father in law is a retired tool and die maker, I’ll be in my shop fabricating something and he’ll be over there asking what kind of tolerance I need, and I have to remind him about hitch pin tolerances. As in, not rattle around too much.What is a farmer tolerance?? Tenthousanths? As in .010 or "tenths" as on .0001?? Most of the time ½ thou (.0005) is plenty close enough for me.......you guys forget I'm a die maker.

I’m just learning, and I’ll also try to keep my sarcasm and joking in check.

All good! Kinda hard me to tell when someone is joking vs. Making fun of me.........It was in reference to a comment I made earlier - my father in law is a retired tool and die maker, I’ll be in my shop fabricating something and he’ll be over there asking what kind of tolerance I need, and I have to remind him about hitch pin tolerances. As in, not rattle around too much.

I’m just learning, and I’ll also try to keep my sarcasm and joking in check.

Want to bet? I've seen it done. I guess if the tap fits, it's good, according to some people.You can not thread an eccentric hole, thee entire hole is out of round. Normally you "turn " the shaft off center creating a cam or eccentric

Would I do it? No.

I think I would have failed my apprenticeship (and gotten beaten by on of the journeyman Toolmakers)Want to bet? I've seen it done. I guess if the tap fits, it's good, according to some people.

Would I do it? No.

We're did ya get the quill/spindle DRO?A few minor upgrades. Digital depth gauge, reads in 0.002" and was pretty easy to install. Some machinist jacks, better than my homemade socket thingies.

View attachment 257059

View attachment 257060

It's not that hard to learn, I taught myself, I need to learn 3d solid molding, (and post processing) so I can define tooling and optimize tool paths, thus generating cnc code, but I degress.......I can teach just about anyone to write programs I a short timeCNC is tough to learn, but you can do so much once you master it. Basically make anything.

Bought a real mill and decommissioned the drill press from milling duty.

Rockwell 21-122 "hobbyist" knee mill. Perfect size for my garage.

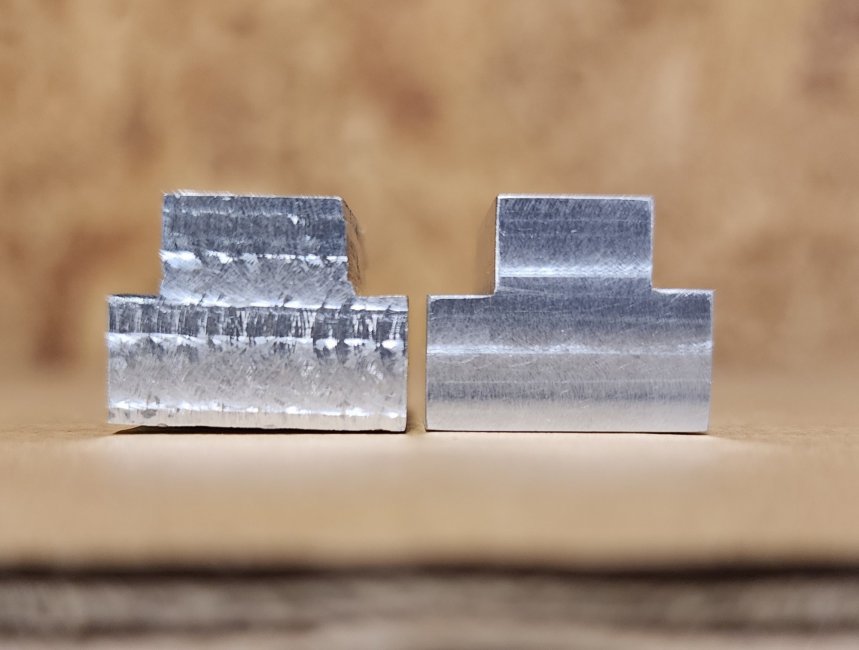

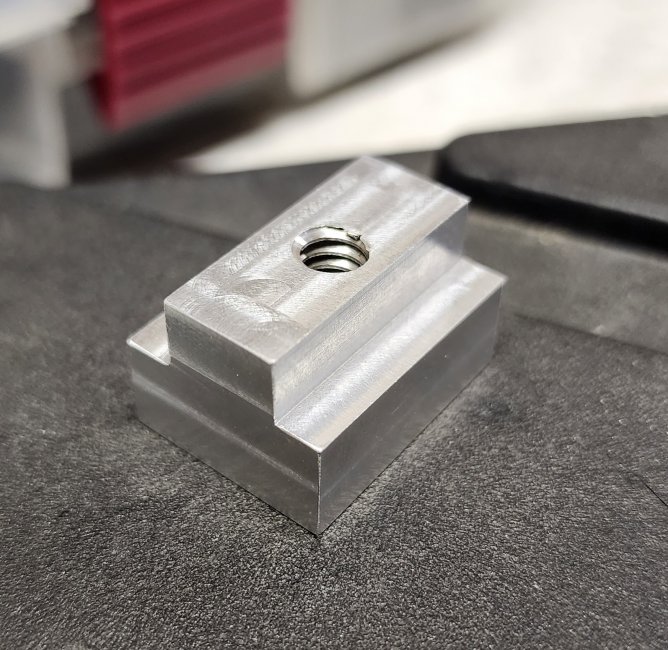

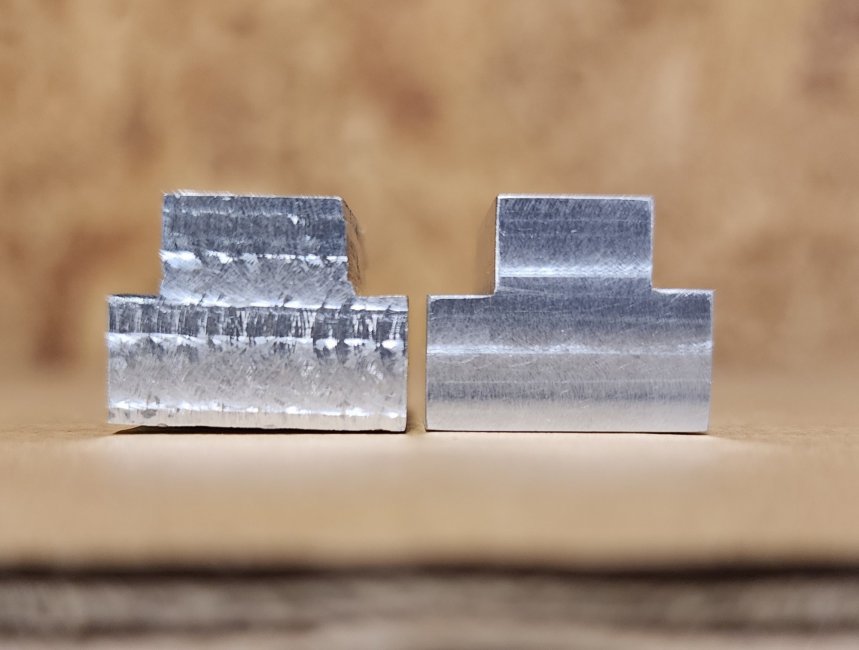

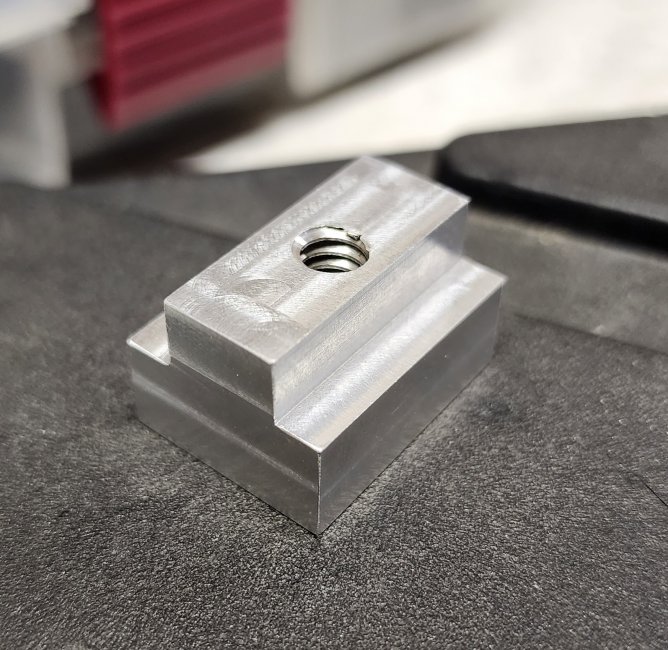

First chips made today. Much better than the drill press setup. Two aluminum scrap pieces used for practice work, left is drill press and right is mill.

I see a few more optics cuts in my future, amongst whatever I else I decide to dive into.

Rockwell 21-122 "hobbyist" knee mill. Perfect size for my garage.

First chips made today. Much better than the drill press setup. Two aluminum scrap pieces used for practice work, left is drill press and right is mill.

I see a few more optics cuts in my future, amongst whatever I else I decide to dive into.

Last edited:

Hello, I’d like to talk to you about the breaker panel behind the millBought a real mill and decommissioned the drill press from milling duty.

Rockwell 21-122 "hobbyist" knee mill. Perfect size for my garage.

View attachment 261839

View attachment 261840

First chips made today. Much better than the drill press setup. Two aluminum scrap pieces used for practice work, left is drill press and right is mill.

I see a few more optics cuts in my future, amongst whatever I else I decide to dive into.

View attachment 261841

View attachment 261842

View attachment 261843

View attachment 261844

-osha

And you have started your apprenticeship.....looks good !Bought a real mill and decommissioned the drill press from milling duty.

Rockwell 21-122 "hobbyist" knee mill. Perfect size for my garage.

View attachment 261839

View attachment 261840

First chips made today. Much better than the drill press setup. Two aluminum scrap pieces used for practice work, left is drill press and right is mill.

I see a few more optics cuts in my future, amongst whatever I else I decide to dive into.

View attachment 261841

View attachment 261842

View attachment 261843

View attachment 261844

Not OSHA ... NEC, National Electrical Code. *** Sheesh *** You'd have thought that I've been speaking a foreign language al this time.Hello, I’d like to talk to you about the breaker panel behind the mill

-osha

OSHA would like to speak to you about the failure to secure the mill to the floor...

Staff online

-

GodFearinGunTotinSuper Moderator

Members online

- sadclownwp

- mcoppers

- spencer rifle

- ryanbr

- EODFXSTI

- Malware

- nettinyahoo

- Bennettjh

- GunsCarsPlanes

- nad63

- littletommy

- crumbflicker

- WhitleyStu

- Work

- KLB

- red_zr24x4

- Snapdragon

- WillH

- JHB

- jim b

- Creedmoor

- Judamonster

- gpasp101

- peterock

- DoggyDaddy

- Hkindiana

- 85Cosmo

- VERT

- jdadkins87

- res04

- GodFearinGunTotin

- rhamersley

- wtburnette

- slims2002

- BeDome

- Timjoebillybob

- rosejm

- BrettonJudy7

- Twangbanger

- Ingomike

- edwea

- snapping turtle

- koenig clone

- Edged Tools

- SouthernStar25

- OneBadV8

- jsx1043

- STAGE 2

- TRL

- Angrysauce

Total: 1,410 (members: 234, guests: 1,176)