You work in Kokomo?Super Alloys , recently got promoted so now I am a supervisor at 27. Specializing in Nickle Cobalt stuff that does not melt and cannot corrode. Very expensive used in aerospace applications. We make the legendary Stellite 6K too

-

Be sure to read this post! Beware of scammers. https://www.indianagunowners.com/threads/classifieds-new-online-payment-guidelines-rules-paypal-venmo-zelle-etc.511734/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How much do you spend on an EDC

- Thread starter Edged Tools

- Start date

The #1 community for Gun Owners in Indiana

Member Benefits:

Fewer Ads! Discuss all aspects of firearm ownership Discuss anti-gun legislation Buy, sell, and trade in the classified section Chat with Local gun shops, ranges, trainers & other businesses Discover free outdoor shooting areas View up to date on firearm-related events Share photos & video with other members ...and so much more!

Member Benefits:

Correct , got hired on right out of college, I am very fortunate to love my job.You work in Kokomo?

I would have loved to worked in Tipton just for the metal knowledge that was available.Correct , got hired on right out of college, I am very fortunate to love my job.

As you know, The rest of it just sucked.

My limited knowledge stops after T1, 4140 round and DM stock, AR 400 and AR500.

When first drilling AR500 plate the engineers at Champion Drill and I became phone friends. I ended up buying a Jauncy 4x4 and using flooded carbide tipped annular cutters and lock drills.

Part of my business was building and rebuilding Vibratory Plow Blades.

Some metals are darn smart. lol

I carry different knifes on different days depending on if there is a Special Task I need to do

Favorite is a Stanley Mini 3.5" ... great for opening boxes and under $5 if I loose it ...

View attachment 211008

I think I just discovered a new EDC? Just what I want. Affordable and easily replaceable that I'm not shy of using roughly to take away from precision sharpness needed for the next thing...

Honestly though, it was the bitholder that sold me to start with.

Last edited:

I would love a utility knife like that one that's assisted opening. Milwaukee could probably find a way to fit a battery on there too. Or at least some pack out clips...I think I just discovered a new EDC? Just what I want. Affordable and easily replaceable that I'm not shy of using roughly to take away from precision sharpness needed for the next thing...

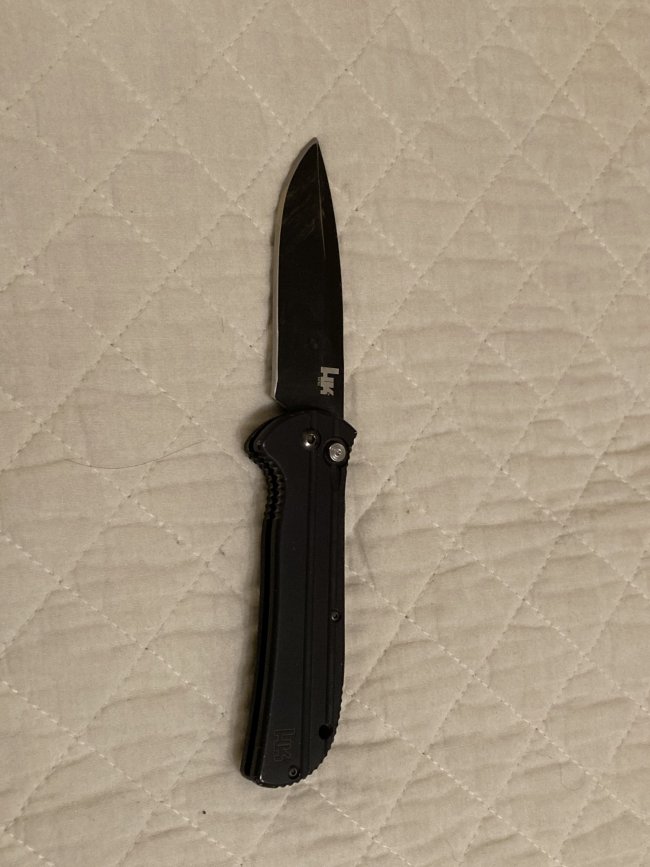

View attachment 239806

I would love a utility knife like that one that's assisted opening...

Might be a money making oportunity for the aftermarket?

.

So in true INGO fashion (see avatar), I’m going to jack this thread…I would have loved to worked in Tipton just for the metal knowledge that was available.

As you know, The rest of it just sucked.

My limited knowledge stops after T1, 4140 round and DM stock, AR 400 and AR500.

When first drilling AR500 plate the engineers at Champion Drill and I became phone friends. I ended up buying a Jauncy 4x4 and using flooded carbide tipped annular cutters and lock drills.

Part of my business was building and rebuilding Vibratory Plow Blades.

Some metals are darn smart. lol

Wondering if you could help me out?

I’ve been pondering a wear question on a piece of equipment for a while… it’s a wheel trencher, Hydromaxx 2600 company link - https://portindustries.com/

On the side of the digging wheel, made up of ‘buckets’, there is a tooth holder that accepts a backhoe bucket tooth. These teeth are wearing faster than normal, and getting more expensive. They do take some serious impacts from rocks, while digging out the trench to the right width.

My question is would it be feasible to weld a 2 1/2” wide by 4” long piece of AR 500 to the tooth holder and build that up as needed?

How do you build up plow blades and would any of that apply?

My everyday carry for many years has been a Spyderco Endura, either partially or fully serrated. Very hard working knife.

I’ll also carry a Gerber Warrant now discontinued, at work during the winter.

at work during the winter.

I’ll also carry a Gerber Warrant now discontinued,

at work during the winter.

at work during the winter.Ive seen plate welded or bolted with body fit or snowplow edge bolts and nuts across the teeth of a bucket to help with wear.So in true INGO fashion (see avatar), I’m going to jack this thread…

Wondering if you could help me out?

I’ve been pondering a wear question on a piece of equipment for a while… it’s a wheel trencher, Hydromaxx 2600 company link - https://portindustries.com/

On the side of the digging wheel, made up of ‘buckets’, there is a tooth holder that accepts a backhoe bucket tooth. These teeth are wearing faster than normal, and getting more expensive. They do take some serious impacts from rocks, while digging out the trench to the right width.

My question is would it be feasible to weld a 2 1/2” wide by 4” long piece of AR 500 to the tooth holder and build that up as needed?

How do you build up plow blades and would any of that apply?

View attachment 239823

I have a bunch of Vermeer LM 35.40 and 42 AR500 plow blanks in 1/2" thick and are ?? 6 1/2" wide and say 30 +" long.

If you would like a few to cut and try I would be more than glad to toss a few in a large flat rate box and ship them to you?

Or if your close a meet and eat?

I can snap a few pics of one tomorrow if your interested.

With smaller plow blades like the walk beside Vermeers, Berkeens, Ditch Witch and other smaller machines I would normally use a plasma and cut out the bullet and wear portion and weld in a new piece of flat stock and bullet.

Larger blades I would add AR flat plate in the needed thickness and then the never ending 7018 buildup and finish with hardface wear bars.

I’ll let you know I’m really don’t have any metallurgy knowledge at all…Ive seen plate welded or bolted with body fit or snowplow edge bolts and nuts across the teeth of a bucket to help with wear.

I have a bunch of Vermeer LM 35.40 and 42 AR500 plow blanks in 1/2" thick and are ?? 6 1/2" wide and say 30 +" long.

If you would like a few to cut and try I would be more than glad to toss a few in a large flat rate box and ship them to you?

Or if your close a meet and eat?

I can snap a few pics of one tomorrow if your interested.

With smaller plow blades like the walk beside Vermeers, Berkeens, Ditch Witch and other smaller machines I would normally use a plasma and cut out the bullet and wear portion and weld in a new piece of flat stock and bullet.

Larger blades I would add AR flat plate in the needed thickness and then the never ending 7018 buildup and finish with hardface wear bars.

Do I assume correctly I could plasma cut the pieces you have into 3”ish by 4”ish pieces without taking the wear or hardness properties out of the AR?

If so I’d be happy to buy your lunch and buy some steel.

I actually have my usual steel supplier checking into what these cut pieces would cost, but they’ll probably be high. Great service, will do whatever, but you pay for it.

We do quite a bit of buildup/hardfacing and would commit to doing that on these teeth as that would be about as quick as changing them out.

I cut most of my plate out myself then on a 4'x4' plasma table. I never noticed any excessive wear or problems with what I cut.I’ll let you know I’m really don’t have any metallurgy knowledge at all…

Do I assume correctly I could plasma cut the pieces you have into 3”ish by 4”ish pieces without taking the wear or hardness properties out of the AR?

If so I’d be happy to buy your lunch and buy some steel.

I actually have my usual steel supplier checking into what these cut pieces would cost, but they’ll probably be high. Great service, will do whatever, but you pay for it.

We do quite a bit of buildup/hardfacing and would commit to doing that on these teeth as that would be about as quick as changing them out.

O'neals saleman stopped in one day and I was cutting some AR and he asked why I didnt get these parts cut by them on a enhanced gang plasma. Back then I was charged just under a buck a cutting foot. I could spend that almost in just consumables much less with adding dry air and elect.

I'll post a few pics tomorrow. At minimum you can cut and try a few different styles for almost nothing.

I cut most of my plate out myself then on a 4'x4' plasma table. I never noticed any excessive wear or problems with what I cut.

O'neals saleman stopped in one day and I was cutting some AR and he asked why I didnt get these parts cut by them on a enhanced gang plasma. Back then I was charged just under a buck a cutting foot. I could spend that almost in just consumables much less with adding dry air and elect.

I'll post a few pics tomorrow. At minimum you can cut and try a few different styles for almost nothing.

Welding Rod

Same vein, how do you feel about hard facing? I know back in the 40's/50's it was a very popular thing to do with our Alloy. 6B would definitely work well for that application

I know The Kennametal name for some reason. I want to say ive used there replacable carbide tipped cutters used on some chain trenchers and asphalt grinders.Welding Rod

www.stellite.com

Same vein, how do you feel about hard facing? I know back in the 40's/50's it was a very popular thing to do with our Alloy. 6B would definitely work well for that application

One plow blade co Triple D uses there cutters as replacable plow blade bullets.

Most of the hard face rod I have is "Stoody" rod.

I have some hardface with chunks of carbide in it that you braze on.

I used it on 12" to 24" percussion drill bits.

This is all very interesting. Not to be a dick or anything, but why don't you gents start a thread in an appropriate forum to discuss it?

You could even post a link to your new thread and visa versa, if you think folks interested in heavy equipment and ditching discussion might be interested in pocket knives and the opposite?

You could even post a link to your new thread and visa versa, if you think folks interested in heavy equipment and ditching discussion might be interested in pocket knives and the opposite?

I mean, it is an edged tool, but yea I get it. Sorry.This is all very interesting. Not to be a dick or anything, but why don't you gents start a thread in an appropriate forum to discuss it?

You could even post a link to your new thread and visa versa, if you think folks interested in heavy equipment and ditching discussion might be interested in pocket knives and the opposite?

Hardface conversation moved over here, albeit awkwardly…

www.indianagunowners.com

www.indianagunowners.com

Redemption of a threadjack gone wrong, or All Things AR500 and Hardfacing.

Moving from the edges tools section, we were having a discussion of impact and abrasive wear on backhoe bucket teeth tips. Will try to quote the relevant conversation and move forward over here.

Members online

- DoggyDaddy

- hhi7410

- Magyars

- gotguns

- DDadams

- TJ Kackowski

- Dirty Steve

- CallSign Snafu

- INPatriot

- jgarcia87

- efd1295

- thedreamer

- Born2vette

- Bosshoss

- BeDome

- Mongo59

- SEIndSAM

- 76caprice

- blain

- Twinks46975

- hoosier21

- Lassiter

- tge45

- slims2002

- OneBadV8

- x34822

- Ozzy17

- Creedmoor

- Merk

- mkgr22

- Steve

- Midwestjimbo

- LeftyGunner

- Jerry downey

- EODFXSTI

- Joegrz308

- jackwagon

- Colt556

- bowhunter_1978

- yotehunt

- syntax357

- Joniki

- S8MS-01904

- SnoopLoggyDog

- morve80

- Mgderf

- JimH

- stndnvn1

- danatkins

- deo62

Total: 1,269 (members: 58, guests: 1,211)