In 2018 I replaced all my Dillon Reloading machines with new 550C machines. 2 years into these, I thought it time to review them. RL 550C Reloader (14261): Reloading: Reloading Machines (dillonprecision.com)

Becoming woke on something that we have redundantly done all of our lives can sometimes be interesting. For instance, it was just this year that I became woke to the fact that the Independent Order of Oddfellows logo reads IOOF instead of my lifetime belief it was 100F. I never slowed down enough to know what the heck it was as I passed graveyards and lodge buildings displaying IOOF. This experience was kind of like realizing all of your life that you had the wrong lyrics to your favorite song as a kid.

My first progressive Dillon was a 450. Being forced to be frugal with my money in those days meant that I used it a lot for everything. Switching between small and large primers, lots of tool heads laying around and a powder hopper that turned black with contaminates was the norm. This machine paid for itself many times over but it was not perfect. I still chuckle at the choice of the name Dillon Precision. When I think of precision, an Indy racecar engine comes to mind, or the CNC fit of moving parts so common in today’s precise manufacturing. I don’t know about you but when working any of today’s progressive presses, they feel and sound more like my old Gleaner combine when bringing in the harvest.

A one size fits all market place machine is needed to keep the cost down for volume production. I get that. However, with the advancement that we have made in automobiles and so many other industries today, I do not believe we have reached the pinnacle of thrashing machines..whoops, I meant reloading machines. I am not an engineer but some Purdue Grad should come up with a CNC Linear small footprint short throw machine for pistol and another for rifles. The precision gear driven case line would keep all ducks in a row so to speak and would be easier to add a power drive. Real precision milled steel die heads taking standard dies would be easy to manufacture as well. Start up would take a huge investment and the engineering would have to be forward thinking. But the end game would be a much better machine that is currently offered in the marketplace today. And it would be a precision machine.

When I was in full gun racing mode back in the day, raising a family and working retail, I had to set up 6 machines in my shop to keep up with my supply of ammo. When the 650 came out I set all six up as caliber specific and kept my 550B’s for special runs. A lot of allowance money was earned by my kids as they got to pull the handle after school to keep me in cartridges. The case feeders and auto indexing of the 650 made my shooting possible and I do not regret those machines. However, as I have been slowing down in my old age, there came some things that I became woke to. I began disliking auto indexing as, whenever there was a stoppage, a round was likely to get in my bin without being crimped. I never had to gauge very much as I kept everything in check so looking for this one uncrimped round always ticked me off and wasted my time. Then there was the high primer issues that plagued my 650’s. Dillon or myself could never ever get the circular primer feed system on a 650 to be consistent. No matter what we did. Again, time wasted, not happy. And finally, the cheesy plastic cams on the 650, would break, wear out, hang up and just simply waste my time some more.

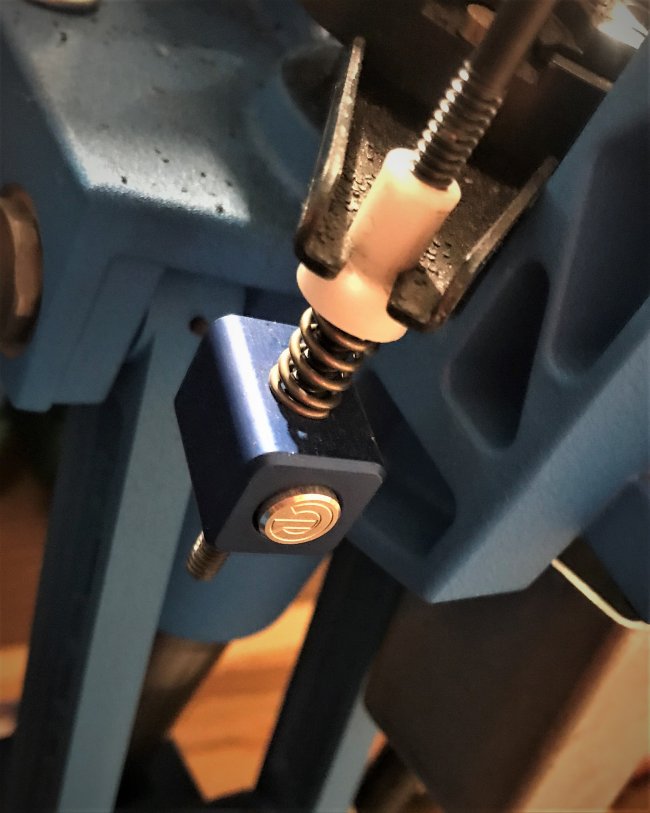

This is why, I outfitted my bench with only 3 550C’s and of course my RCBS RockChucker. Rock Chucker Supreme Press | RCBS. Since I run 4 Dillon powder measures between the three Dillon machines, I added the adjustable powder knobs for easier and quicker adjustments. 5-Pack Dillon Powder Control / Measurement / Adjustment Knobs! Free Ship! | eBay . Moving forward, since I am running less machines, my process of powder and tool head swapping was made easier by a quick release powder funnel collar and rod wingnut. Dillon 550 – EntirelyCrimson. By marking the name of powder on the end of my powder bushing, I can change complete calibers for reloading in about 3 minutes. I have two 550C’s dedicated to large primers and the other one to small primers, so that I do not have to waste time with primer setups.

The primer catch on the 550C is the same as they have been and requires tweaking from time to time but I can live with that. I have tried the catches with clear hoses that drop into a can on the floor prefer to just dump the bin when it’s time.

The new 550C machines come with easier ways to lubricate by using a small grease gun. The 550C also includes a few small changes in the frame casting. It is important to follow the guidelines by Dillon to lubricate the main shaft with 30 SAE motor oil as you do not want to use a penetrating oil on a reloading machine. I have tried all the Dillon accessories like bullet trays, roller handles and such but I like to maintain smaller footprints on my bench as the more calibers you load, the more bullets and cases you have taking up space as it is. Do I miss the case feeders? I would if I was still shooting 40,000 rounds a year and working full time. The nice thing about the manual 550C is, I get to handle each case which promotes inspection and such. I like handling the bullets as well. My rate for quality trouble free ammo is about 400 an hour and I can live with that these days.

I see constantly on Facebook, you tube reviews and here in this forum that many hand loaders try to get by with an insecure bench for their machines. The machines are sloppy enough without having to worry about floppy movement and flex. I use solid Southern Yellow Pine and 4x4 supports for any handloading bench I have made. I do not like weeble wobble benches. The 550C’s base go directly onto the 2z12’s.

Sometimes I am slow to catch on but I like the set up that I have now. With 5 grandkids I am trying to stay up with being Rad and adopting to the new generation. However, with my hearing challenge, at the range when the Asian shooter was telling me he was woke, I offered to loan him some money. My bad. Waking up to a new era for me in going with manual indexing machines is okay going forward. Perhaps that makes me an OddFellow.

Good Shooting

View attachment 94245 View attachment 94246 View attachment 94247 View attachment 94248 View attachment 94249 View attachment 94250 View attachment 94251 View attachment 94252 View attachment 94253

Becoming woke on something that we have redundantly done all of our lives can sometimes be interesting. For instance, it was just this year that I became woke to the fact that the Independent Order of Oddfellows logo reads IOOF instead of my lifetime belief it was 100F. I never slowed down enough to know what the heck it was as I passed graveyards and lodge buildings displaying IOOF. This experience was kind of like realizing all of your life that you had the wrong lyrics to your favorite song as a kid.

My first progressive Dillon was a 450. Being forced to be frugal with my money in those days meant that I used it a lot for everything. Switching between small and large primers, lots of tool heads laying around and a powder hopper that turned black with contaminates was the norm. This machine paid for itself many times over but it was not perfect. I still chuckle at the choice of the name Dillon Precision. When I think of precision, an Indy racecar engine comes to mind, or the CNC fit of moving parts so common in today’s precise manufacturing. I don’t know about you but when working any of today’s progressive presses, they feel and sound more like my old Gleaner combine when bringing in the harvest.

A one size fits all market place machine is needed to keep the cost down for volume production. I get that. However, with the advancement that we have made in automobiles and so many other industries today, I do not believe we have reached the pinnacle of thrashing machines..whoops, I meant reloading machines. I am not an engineer but some Purdue Grad should come up with a CNC Linear small footprint short throw machine for pistol and another for rifles. The precision gear driven case line would keep all ducks in a row so to speak and would be easier to add a power drive. Real precision milled steel die heads taking standard dies would be easy to manufacture as well. Start up would take a huge investment and the engineering would have to be forward thinking. But the end game would be a much better machine that is currently offered in the marketplace today. And it would be a precision machine.

When I was in full gun racing mode back in the day, raising a family and working retail, I had to set up 6 machines in my shop to keep up with my supply of ammo. When the 650 came out I set all six up as caliber specific and kept my 550B’s for special runs. A lot of allowance money was earned by my kids as they got to pull the handle after school to keep me in cartridges. The case feeders and auto indexing of the 650 made my shooting possible and I do not regret those machines. However, as I have been slowing down in my old age, there came some things that I became woke to. I began disliking auto indexing as, whenever there was a stoppage, a round was likely to get in my bin without being crimped. I never had to gauge very much as I kept everything in check so looking for this one uncrimped round always ticked me off and wasted my time. Then there was the high primer issues that plagued my 650’s. Dillon or myself could never ever get the circular primer feed system on a 650 to be consistent. No matter what we did. Again, time wasted, not happy. And finally, the cheesy plastic cams on the 650, would break, wear out, hang up and just simply waste my time some more.

This is why, I outfitted my bench with only 3 550C’s and of course my RCBS RockChucker. Rock Chucker Supreme Press | RCBS. Since I run 4 Dillon powder measures between the three Dillon machines, I added the adjustable powder knobs for easier and quicker adjustments. 5-Pack Dillon Powder Control / Measurement / Adjustment Knobs! Free Ship! | eBay . Moving forward, since I am running less machines, my process of powder and tool head swapping was made easier by a quick release powder funnel collar and rod wingnut. Dillon 550 – EntirelyCrimson. By marking the name of powder on the end of my powder bushing, I can change complete calibers for reloading in about 3 minutes. I have two 550C’s dedicated to large primers and the other one to small primers, so that I do not have to waste time with primer setups.

The primer catch on the 550C is the same as they have been and requires tweaking from time to time but I can live with that. I have tried the catches with clear hoses that drop into a can on the floor prefer to just dump the bin when it’s time.

The new 550C machines come with easier ways to lubricate by using a small grease gun. The 550C also includes a few small changes in the frame casting. It is important to follow the guidelines by Dillon to lubricate the main shaft with 30 SAE motor oil as you do not want to use a penetrating oil on a reloading machine. I have tried all the Dillon accessories like bullet trays, roller handles and such but I like to maintain smaller footprints on my bench as the more calibers you load, the more bullets and cases you have taking up space as it is. Do I miss the case feeders? I would if I was still shooting 40,000 rounds a year and working full time. The nice thing about the manual 550C is, I get to handle each case which promotes inspection and such. I like handling the bullets as well. My rate for quality trouble free ammo is about 400 an hour and I can live with that these days.

I see constantly on Facebook, you tube reviews and here in this forum that many hand loaders try to get by with an insecure bench for their machines. The machines are sloppy enough without having to worry about floppy movement and flex. I use solid Southern Yellow Pine and 4x4 supports for any handloading bench I have made. I do not like weeble wobble benches. The 550C’s base go directly onto the 2z12’s.

Sometimes I am slow to catch on but I like the set up that I have now. With 5 grandkids I am trying to stay up with being Rad and adopting to the new generation. However, with my hearing challenge, at the range when the Asian shooter was telling me he was woke, I offered to loan him some money. My bad. Waking up to a new era for me in going with manual indexing machines is okay going forward. Perhaps that makes me an OddFellow.

Good Shooting

View attachment 94245 View attachment 94246 View attachment 94247 View attachment 94248 View attachment 94249 View attachment 94250 View attachment 94251 View attachment 94252 View attachment 94253

************************

Original Thread Here

https://www.indianagunowners.com/fo...ng/489428-dillon-550c-review.html#post8522173

Original Thread Here

https://www.indianagunowners.com/fo...ng/489428-dillon-550c-review.html#post8522173

Attachments

-

IMG_0630 (002).jpg1 MB · Views: 6

IMG_0630 (002).jpg1 MB · Views: 6 -

IMG_0616 (002).jpg614.1 KB · Views: 5

IMG_0616 (002).jpg614.1 KB · Views: 5 -

IMG_0618 (002).jpg586.2 KB · Views: 5

IMG_0618 (002).jpg586.2 KB · Views: 5 -

IMG_0620 (002).jpg641 KB · Views: 5

IMG_0620 (002).jpg641 KB · Views: 5 -

IMG_0619 (002).jpg576.4 KB · Views: 5

IMG_0619 (002).jpg576.4 KB · Views: 5 -

IMG_0622 (002).jpg796.9 KB · Views: 4

IMG_0622 (002).jpg796.9 KB · Views: 4 -

IMG_0623 (002).jpg753.7 KB · Views: 4

IMG_0623 (002).jpg753.7 KB · Views: 4 -

IMG_0627 (002).jpg754.9 KB · Views: 5

IMG_0627 (002).jpg754.9 KB · Views: 5 -

IMG_0632 (002).jpg711.9 KB · Views: 5

IMG_0632 (002).jpg711.9 KB · Views: 5

Last edited by a moderator: