-

Be sure to read this post! Beware of scammers. https://www.indianagunowners.com/threads/classifieds-new-online-payment-guidelines-rules-paypal-venmo-zelle-etc.511734/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dillon 550 handloading for accuracy

- Thread starter Paul 7.62

- Start date

The #1 community for Gun Owners in Indiana

Member Benefits:

Fewer Ads! Discuss all aspects of firearm ownership Discuss anti-gun legislation Buy, sell, and trade in the classified section Chat with Local gun shops, ranges, trainers & other businesses Discover free outdoor shooting areas View up to date on firearm-related events Share photos & video with other members ...and so much more!

Member Benefits:

Welcome to INGO @Paul 7.62

If you use spherical powder in a standard measure, you'll get +/- 0.1gn accuracy. Tool heads don't matter at all when it comes to powder drops. All bullet seating depths are constant even with TH flex.

If you use spherical powder in a standard measure, you'll get +/- 0.1gn accuracy. Tool heads don't matter at all when it comes to powder drops. All bullet seating depths are constant even with TH flex.

The only issue I have on my 550 is consistent powder throws with big charges, like over 45 grains or so. I weigh every one and trickle what is needed. Pistol and smaller rifle charges are on the nut.

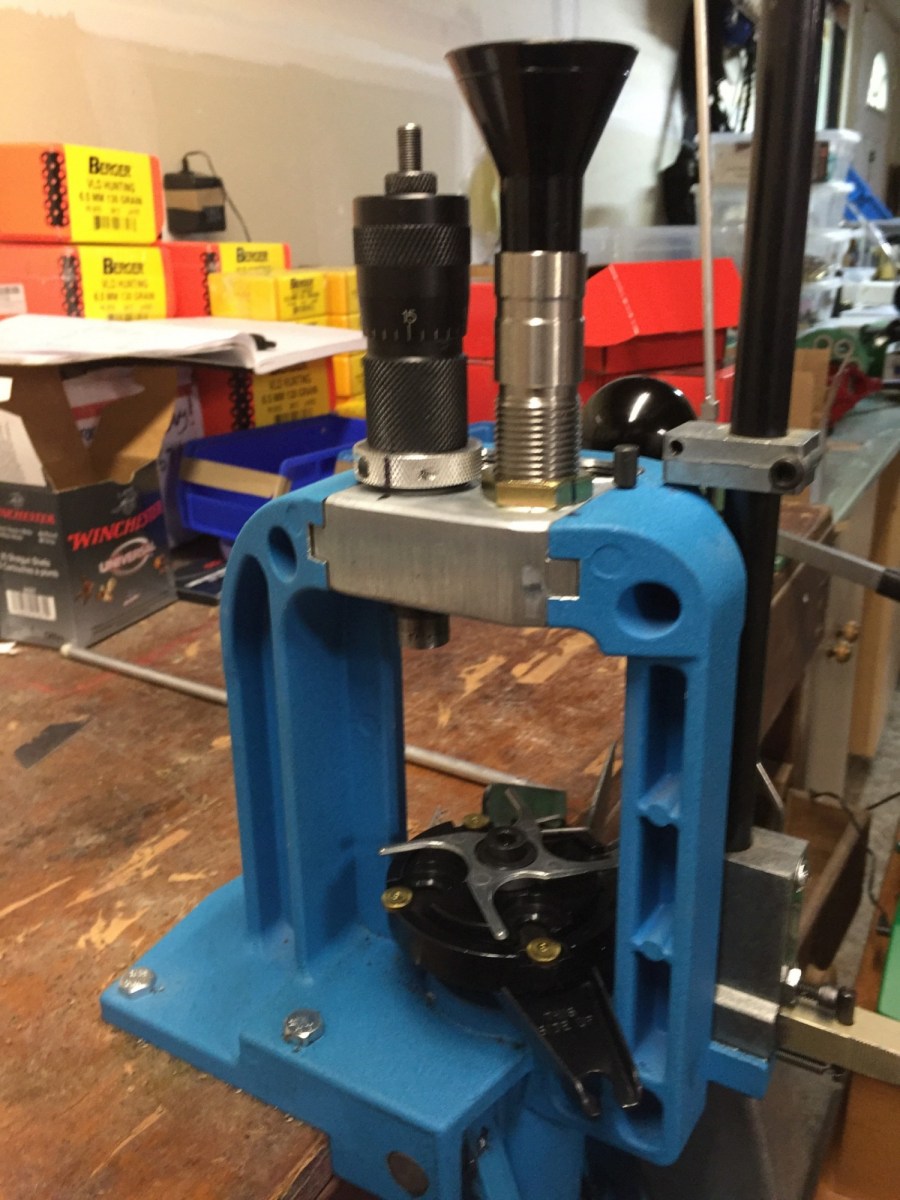

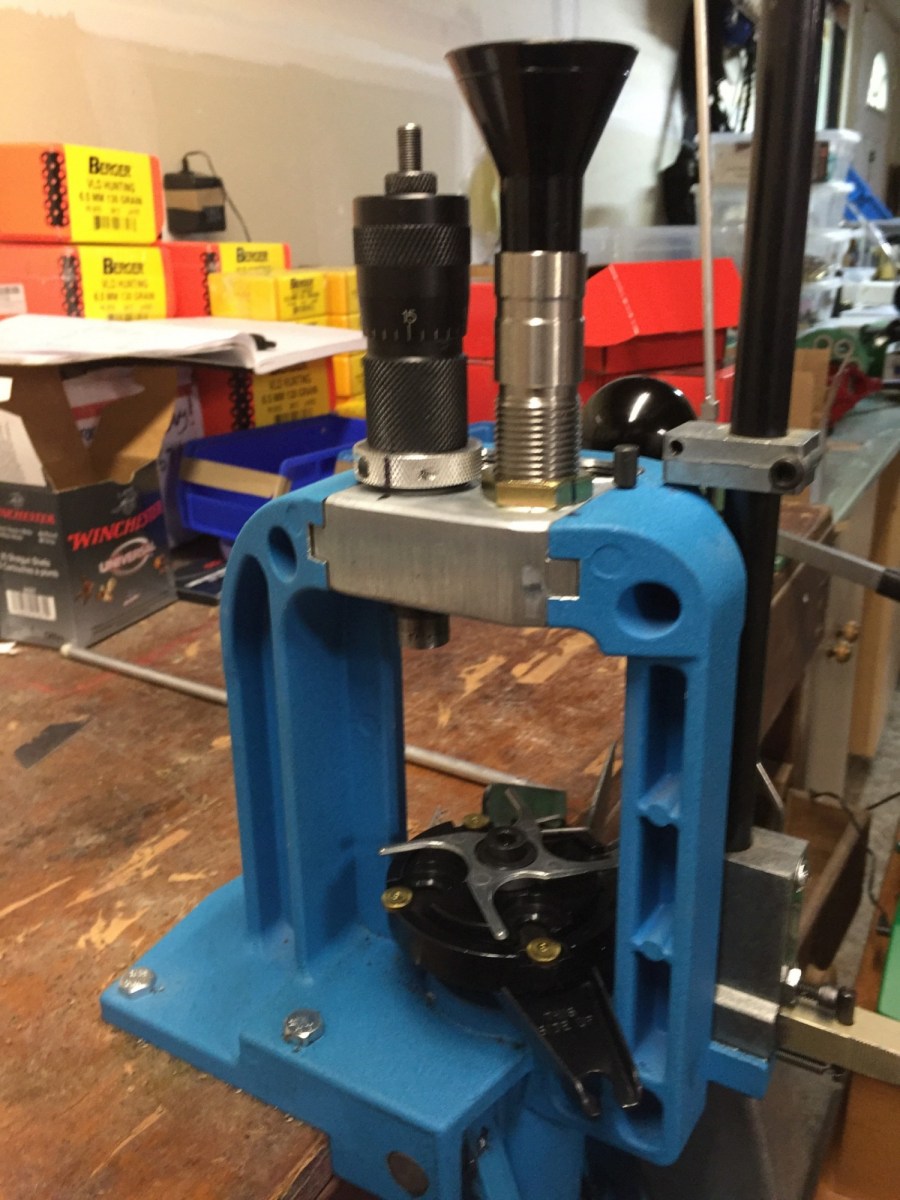

I don't handload with ball powder, as I prefer powders like H4895, IMR4064, H4350, H4831 and H4831 SC. My 550 is set up to size cases on the first tool head, then switch to weighted charges on the second tool head. I am using Armanov tool heads and die rings. Cases are primed on a Holland/RCBS primer seater 4 thousands below case head. All cases are neck turned, and primer pockets are cut to same depth.

Tool heads are set up as follows: Station 1 Body sizing die, Station Two open, Station 3 Bushing bump die, Station 4 Mandrel die.

Seating tool head: Station 1 blank, Station 2 powder drop (using a V4 to measure powder to .02 of a grain), Station 3 bullet seating.

Seating tool head: Station 1 blank, Station 2 powder drop (using a V4 to measure powder to .02 of a grain), Station 3 bullet seating.

Order a magnum powder bar from Dillon. Problem solved.The only issue I have on my 550 is consistent powder throws with big charges, like over 45 grains or so. I weigh every one and trickle what is needed. Pistol and smaller rifle charges are on the nut.

You are using your Dillon past it's capabilities. I applaud you.Tool heads are set up as follows: Station 1 Body sizing die, Station Two open, Station 3 Bushing bump die, Station 4 Mandrel die.

Seating tool head: Station 1 blank, Station 2 powder drop (using a V4 to measure powder to .02 of a grain), Station 3 bullet seating.

I've never seen someone use multiple tool heads - eight stages - on a four stage press. If you're trying to impress us, you have. And if you're trying to get fifty posts, you're doing a great job. Those are quality posts.

If I want to spend more time on reloading, I single stage reload on a Forster Co-Ax.

I have reloaded 223rem on my Dillon 550 by first prepping & sizing brass with a full length bushing die (no expander) on a single stage. Then brass has lube washed off/dried. Primer seating done off press.

On the 550, I would carbide mandrel neck expand (no lube needed), powder charge with Dillon measure, seat with Forster Bench Rest seater (not micrometer). They turned out good.

I tried that after reading about others using Dillon 550 for accuracy loads. Many referred to David Tubb reloading on a Dillon 550,

www.snipershide.com

www.snipershide.com

www.65guys.com

www.65guys.com

I have reloaded 223rem on my Dillon 550 by first prepping & sizing brass with a full length bushing die (no expander) on a single stage. Then brass has lube washed off/dried. Primer seating done off press.

On the 550, I would carbide mandrel neck expand (no lube needed), powder charge with Dillon measure, seat with Forster Bench Rest seater (not micrometer). They turned out good.

I tried that after reading about others using Dillon 550 for accuracy loads. Many referred to David Tubb reloading on a Dillon 550,

How good is a Dillon 550 for accuracy drive reloading?

I have a Dillon 550 and a few RCBS single stage Rockchuckers. I use the 550 for mainly 'bulk' type rounds like 45ACP and 223/5.56 for my carbine where I am the greatest factor in accuracy, not the round. Regardless, everything I've produced through the 550 is prepped and measured just like I...

Precision from a Progressive Reloader

We really enjoy our time at the reloading bench, but have more fun at the firing line. As part of our journey we have explored various methods to speed up the reloading process without sacrificing …

www.65guys.com

www.65guys.com

You are being redirected...

forum.accurateshooter.com

High Power matchammo

Greetings all, This is my first post here and I'm very happy I found this Dillon-forum as I have a 550 and 650 which I love to play around with. My main interest is High Power competition (100-600 meters). As you might know it is possible to load matchquality ammo on the 550, as demonstrated by J...

forums.brianenos.com

This guy is doing it RIGHT. Armanov floated and all. The dillons are more than able to load precision, setup like this. I’m running a 750 very similar, auto trickler V4 for powder (about to try out the super trickler), but I seat my bullets on an inline with an LE Wilson.

I am a P-dog shooter so need to load lots of ammo for a trip each year, about 3000 rounds. All rounds are loaded long and then seated in a arbor press with a inline seating die the day before they are used. So evening goes like this, clean up, eat dinner, then prep rifles for an hour soak, break out ammo for the next day and seat bullets, finish barrel cleaning with JB bore paste and Kroil. Run patch of denatures alcohol thru bore, let dry and then a patch of HBN2 mixed in a slurry of alcohol. Bullets are all coated in HBN2 to reduce copper fouling and keep carbon build up down.

I am a P-dog shooter so need to load lots of ammo for a trip each year, about 3000 rounds. All rounds are loaded long and then seated in a arbor press with a inline seating die the day before they are used. So evening goes like this, clean up, eat dinner, then prep rifles for an hour soak, break out ammo for the next day and seat bullets, finish barrel cleaning with JB bore paste and Kroil. Run patch of denatures alcohol thru bore, let dry and then a patch of HBN2 mixed in a slurry of alcohol. Bullets are all coated in HBN2 to reduce copper fouling and keep carbon build up down.

Had to look it up...

I have my 550's 223 toolhead set up as assembly only (powder fill, seater, factory crimp) and I do all my case prep on my single stage/hand prime. When I'm trying to build a load I throw/trickle and fill before I load them into the press.

With 223 you can increase production with the case feeder from DAA, Case feederI have my 550's 223 toolhead set up as assembly only (powder fill, seater, factory crimp) and I do all my case prep on my single stage/hand prime. When I'm trying to build a load I throw/trickle and fill before I load them into the press.

Yes I reload for accuracy on a Dillon 550. I use spherical powder and check the powder every 5 loads. I also got the Inline Fabrication tool head screw down kit and followed the direction to tap and die to the letter. Installed my dies after the tool head screw down was installed as instructed. Consistency of COAL improved dramatically. Concentricity also improved. Patience and carefulness is the key to consistently accurate loads. My  !

!

!

!Staff online

-

KellyinAvonBlue-ID Mafia Consigliere

-

GodFearinGunTotinSuper Moderator

-

d.kaufmanStill Here

Members online

- Lee9

- Fire Lord

- yeahbaby

- Bobby

- red_zr24x4

- edporch

- INgunowner

- Throwsstones

- dvd1955

- KellyinAvon

- freekforge

- flint stonez

- Cmustang

- Wolfhound

- opus1776

- johnb62

- Titanium_Frost

- wingrider1800

- Dave2393

- Ingomike

- ZurokSlayer7X9

- Firehawk

- daddyusmaximus

- JTL165

- actaeon277

- worddoer

- mshogren

- 10mm

- indyjohn

- sescbo

- Big Hank

- K9stang

- GodFearinGunTotin

- rxer

- Eagle

- Highstandard

- ruger44srh

- Mike227

- Gandalf

- 812 rimfire

- d.kaufman

- jh101

- Fallschirmjaeger

- KMaC

- buckwacker

- 2tonic

- Ark

- Zombie

- BOLTGUN

- littletommy

Total: 1,757 (members: 280, guests: 1,477)