I was approached by an INGO'er several weeks ago about custom loading 300 Savage ammo for a Savage Model 99 lever action. He noted he didn't have any brass to provide, and after searching, I found that it was upwards of $2 per casing. A little more research and some thinking, I realized I could make the brass out of 308 Win brass, cut down and trimmed, and it would be significantly less expensive (although much harder on the hands.)

I started with PPU virgin 308 brass.

Using a table top chop saw (not shown) to remove 0.025" from the neck of the 308 Win brass, the brass was formed with the Redding 300 Savage die. Afterward, it was trimmed down in the Lyman Xtreme trimmer to 1.861" OAL.

Each case was then checked for uniform mouth trimming and even shoulders.

Each case was then chamfered and deburred - inside and out.

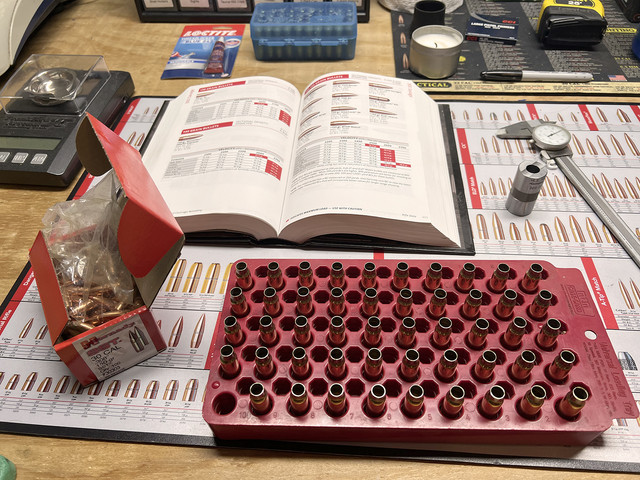

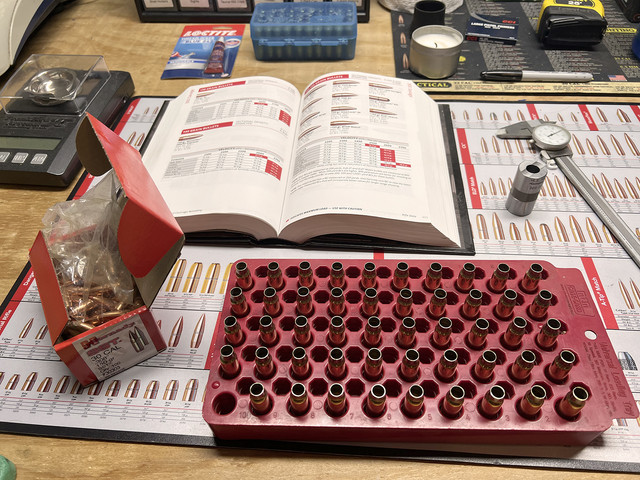

After a quick spin in the tumbler to remove all the shavings and case forming lube, they were on to the bench.

Federal 210 Large Rifle primers, and 44.0gns of RL-17 for an approximate velocity of 2500fps.

I wanted this project to be fun, so I tracked down the Hornady 150gn SST that's made specifically for the 300 Savage. Hard to find but really good bullets.

Finish it all up with the Lee Factory Crimp (for the rotary magazine in the Savage Model 99)

Final OAL and quality control checks - at this point each piece of brass has been through the case gauge four times.

Last and final check:

And packaged, ready to go out.

This was a particularly satisfying project due completely to making the brass from scratch. It was difficult and my hands are hurting, but this is the magic of reloading. If you can't find what you need, make it yourself.

I'm excited to get reviews from the purchaser. I'm sending 50 rounds to start for function testing in his rifle, then more once I get a report.

Happy Thanksgiving, and thanks for reading.

I started with PPU virgin 308 brass.

Using a table top chop saw (not shown) to remove 0.025" from the neck of the 308 Win brass, the brass was formed with the Redding 300 Savage die. Afterward, it was trimmed down in the Lyman Xtreme trimmer to 1.861" OAL.

Each case was then checked for uniform mouth trimming and even shoulders.

Each case was then chamfered and deburred - inside and out.

After a quick spin in the tumbler to remove all the shavings and case forming lube, they were on to the bench.

Federal 210 Large Rifle primers, and 44.0gns of RL-17 for an approximate velocity of 2500fps.

I wanted this project to be fun, so I tracked down the Hornady 150gn SST that's made specifically for the 300 Savage. Hard to find but really good bullets.

Finish it all up with the Lee Factory Crimp (for the rotary magazine in the Savage Model 99)

Final OAL and quality control checks - at this point each piece of brass has been through the case gauge four times.

Last and final check:

And packaged, ready to go out.

This was a particularly satisfying project due completely to making the brass from scratch. It was difficult and my hands are hurting, but this is the magic of reloading. If you can't find what you need, make it yourself.

I'm excited to get reviews from the purchaser. I'm sending 50 rounds to start for function testing in his rifle, then more once I get a report.

Happy Thanksgiving, and thanks for reading.

Last edited: